Side scuttle (porthole) knocked out by wave impact

- Safety Flash

- Published on 31 July 2024

- Generated on 11 January 2026

- IMCA SF 15/24

- 3 minute read

Jump to:

A large wave hit a vessel and a side scuttle (porthole) in one of the cabins broke loose from its frame.

What happened?

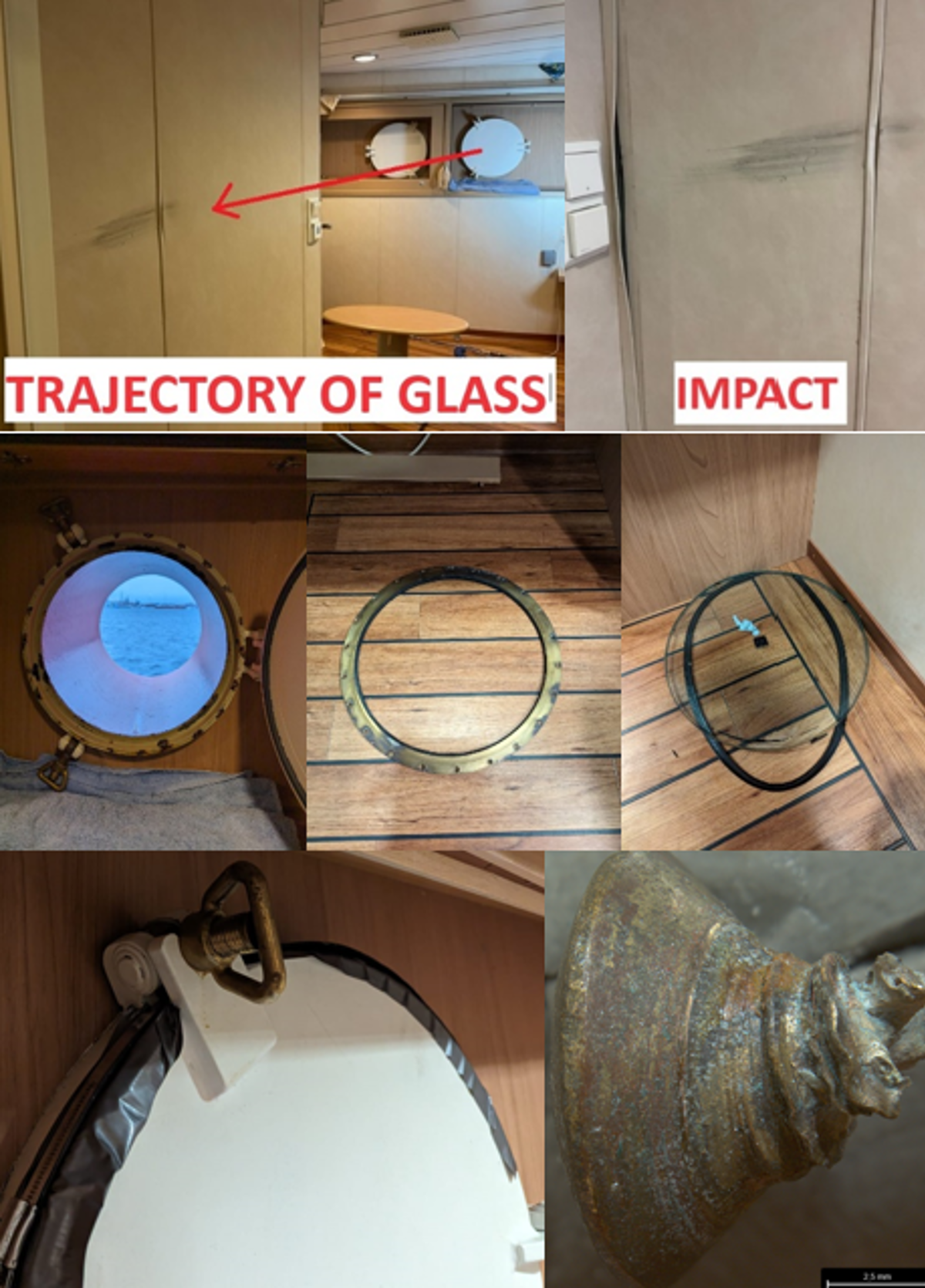

While a platform supply vessel was on passage through heavy seas, a large wave hit the vessel and a side scuttle (porthole) in one of the cabins broke loose from its frame, and was violently propelled across the cabin. A crew member sleeping in the cabin at the time was awakened by the impact and ingress of cold water. Personal effects were destroyed and significant repairs were required to the cabin and the scuttle.

Our member notes that under slightly different circumstances the incident could easily have been a fatality, had someone been in the line of fire of the glass pane, frame, and screw heads. The weight of the glass pane was over 6kg and it was projected over 3m by the pressure of air and water.

What went right?

- The crew member immediately closed the deadlight over the missing glass pane.

- The vessel crew acted promptly – within 30 minutes – to clean up approximately 150 litres of water and all the debris.

What went wrong?

- The vessel was hit by what was considered to be an extra large wave. Conditions at the time Beaufort gale force 8 from the south, seas 2.5m-4m. The vessel was steaming 138° at about 6 knots. Our member noted “wind direction, wind wave direction and swell direction being almost 90 degrees apart, it is not unlikely that a joining of wave energy might have formed hitting the vessel at a worst-case angle to starboard bow and scuttle.”

- With water and air pushing into recess and pipe of the scuttle, all 22 screws sheared simultaneously, and the pressure built up sent the glass, glass retainer ring and screw heads across the cabin;

- When glass and glass retainer ring broke loose, there was nothing for the deadlight to seal against and duct tape had to be used for temporary weatherproofing.

- There had been previous maintenance of some scuttles following slight leakage, but nothing on record for the one that failed in this incident. It is however possible that at some point, someone with good intentions has taken upon themselves to tighten up the screws if observing minor leaks or drops. With specified max torque for brass screws per maker advice being 4N, there is not much force needed before the screws become overtightened.

What was the cause?

Following detailed metallurgical investigation of failed screws/bolts, it was felt that the cause the incident was that the 22 screws holding the glass and glass frame did not have adequate strength to withstand the force of the wave that hit the way it did. The screws provided were poorly manufactured and had been overtightened during installation or during service life.

Actions

- Checked all other scuttle glass holder screws.

- Overhauled all scuttles during next dry dock which was scheduled a few months after the incident.

- Detailed discussions with metallurgists relating to metal screws.

- Discussions with both the supplier of the scuttle and the original designer of the vessel.

- Amended procedure for required use of cabin deadlights in heavy weather.

- Added signage to discourage overtightening screws of the glass retainer ring.

Related Safety Flashes

-

IMCA SF 05/24

27 February 2024

-

-

IMCA SF 19/19

12 August 2019

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.