IN 1681 – Human and organisational performance

- Information Note

- Published on 30 May 2024

- 7 minute read

Jump to:

1. Executive summary

In recent years, interest in Human and Organisational Performance (HOP) has increased with both client and Member organisations adopting this as an approach to improving safety and operational outcomes. HOP is the most common name for several similar schools of thought that include ‘Safety Differently’; ‘Safety I Safety II’ and to a certain extent, ‘High Reliability Organisations’ and ‘Resilience Engineering’.

The historical view of safety has been that organisations considered their technologies, operational procedures, and safety management systems as being robust, reliable, and fit for purpose. Incidents and accidents only occurred when workers interacted with them and so drew the conclusion that the problem must lie with the worker. This approach gave rise to Human Factor (HF) Engineering (matching the worker with the technology) and Behaviour-based Safety (BBS) (fix the worker). HF and BBS played their role through the 1970s, 80s and 90s but once again, injury statistics started to plateau.

HOP was born out of the safety science community and took a fresh approach to how the worker is viewed. In essence, HOP is about learning and understanding how humans and organisations interact to accomplish work. HOP is a philosophy that allows organisations to build error-tolerant systems. HOP accepts that it is not realistic to expect perfection from workers or processes.

2. Background

Building on the earlier work of Jens Rasmussen, James Reason and David Woods; Erik Hollnagel, Sidney Dekker, and Todd Conklin proposed new ways of understanding how work is performed.

3. Safety II

Professor Erik Hollnagel proposed his Safety II theory in 2010. He stated that organisations traditionally focused on what goes wrong in safety and then investigated these to improve. He suggested that if we want to learn about safety, we should be studying things that are safe, and the work which goes well, to understand why that is the case, so that we can support work better in the future.

3. Safety differently

Professor Sidney Dekker in 2012 proposed Safety Differently as an extension of the ideas within Resilience Engineering (the capabilities of a safety system to deal with unanticipated events) and Safety II, and suggested three key changes that organisations should make in relation to how they conceptualise and approach safety management:

- People are the solution, not a problem to control.

- Safety is an ethical responsibility, not bureaucratic accountability.

- Safety is the presence of positive capacities, not the absence of negative events.

4. Human and Organisational Performance (HOP)

Building on work on Human Performance by the US Department of Energy, in the early 2000s, Dr Todd Conklin promoted Human and Organisational Performance. Dr Conklin proposes five core principles of Human and Organisational Performance:

- Error is normal.

- Management response matters.

- Systems drive behaviour.

- Blame fixes nothing.

- Learning is vital.

5. Work as imagined vs. work as performed

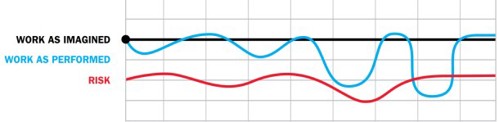

One of the basic tenets of HOP is ‘Work as Imagined vs. Work as Performed’ and can be depicted in a model known as ‘Black Line Blue Line’, as illustrated below.

In this model, a task or procedure is depicted as a black line. The line is very straight and denotes the way that the task is performed in the planner’s mind; each time the planner runs the task through their mind, the task is performed in the same optimal way, every time. The blue line denotes how the task is actually performed. It can either be above the black line, indicating that the task was performed better than the planner imagined, or below the black line indicating that the task was not performed how the planner imagined.

Risk is represented by a red line. Risk is not a constant; it ebbs and flows as stages of the task progress and conditions change. Where the risk increases and the blue line deviates from the task plan or risk assessment and meet, is where incidents occur. The black line can represent any expectation we set for workers such as housekeeping, procedures, risk assessments, etc.

The HOP philosophy accepts that this work variability exists and may be caused by a number of factors that may or may not be within the control of the worker and/or the organisation. By acknowledging and trying to understand the blue line, organisations will start to understand where the blue line is, rather than believing that all work is conducted on the black line and then being surprised to learn, post-incident, that it was not.

6. HOP is a philosophy

HOP is not a suite of tools or procedures that can be purchased off-the-shelf. HOP is a philosophy based upon the work of the professors mentioned above and the growing HOP community who have progressed the ideas further. HOP training and education should be provided to an organisation’s management so that the philosophy can be used to influence revision of the organisation’s policies and procedures, and used when creating new programmes to better learn from everyday work, not just from failures. It should not be required to train frontline workers in HOP principles. Frontline workers should experience HOP through the new ways of engagement they encounter due to the organisation’s new way of thinking.

7. HOP tools

Traditionally, organisations only learnt from the outputs of incident investigations. As previously mentioned, Erik Hollnagel observed that work results in success considerably more often than it results in a failure. By limiting learning to failures, organisations limit the opportunities to learn and improve. The challenge in the HOP community is to develop tools that will enable organisations to learn from normal work (the blue line).

Some tools that have been developed include:

- Leadership / Gemba walk.

- Useful questions.

- After action reviews.

- Work insight / observations.

- Walk-through / talk-throughs.

- Procedure walkdowns.

- Learning teams.

8. Bibliography

Books

- Pre-Accident Investigations: An Introduction to Organizational Safety, Todd Conklin.

- The Field Guide to Understanding Human Error, Sidney Dekker.

- Safety I and Safety II, The Past and Future of Safety Management, Erik Hollnagel.

- Resilience Engineering, Concepts and Precepts, David D Woods, edited by Eril Hollnagel.

- Risk-Based Thinking, Tony Muschara.

- 10 ideas to make safety suck less, Sam Goodman.

Papers – essentials

- Jim Howie: “The New View of Health and Safety”: Safety Solutions: January 2015:

www.newviewhs.com - Gantt, Ron. “Safety Differently: A New View of Safety Excellence.” Paper presented at the ASSE

Professional Development Conference and Exposition, Denver, Colorado, USA, June 2017

Human and organisational performance.

Papers – a “shallow” dive

- Cook, Matt “Deploying Human Performance: Where Do We Start?” Paper presented at the SPE

Health, Safety, Security, Environment, & Social Responsibility Conference – North America, New

Orleans, Louisiana, USA, April 2017. doi: https://doi.org/10.2118/184468-MS. - Brent L Sutton, Brent Robinson, Jeffery Lyth, Todd E Conklin “Learning from Everyday Work: New View of Safety Discussion White-paper”: Learning Teams Inc, November 1, 2021.

Papers – Deep Dive

- David J. Provan, Andrew J. Rae, Sidney W.A. Dekker, “An ethnography of the safety professional’s

dilemma: Safety work or the safety of work?”, Safety Science, Volume 117, 2019, Pages 276-289,

ISSN 0925-7535, https://doi.org/10.1016/j.ssci.2019.04.024. - US Department of Energy: DOE Standard: Human Performance Improvement Handbook Volumes

1 & 2: DOE-HDBK-1028-2009: June 2009.

Websites and podcasts

- Safety Differently.

- Pre-accident Podcast.

- HOP Coach.

- Safety on Tap.

- Safety of Work.

- Forge Works.

- The HOP Nerd.

Videos

- YouTube – Safety Differently – The Movie.

- YouTube – 2018 USW HSE Conference: The New View of Safety with Todd Conklin.

- Being human | Toolbox (energyinst.org).