Injury caused by closing fire flap

- Safety Flash

- Published on 6 December 2020

- Generated on 2 March 2026

- IMCA SF 33/20

- 2 minute read

Jump to:

What happened?

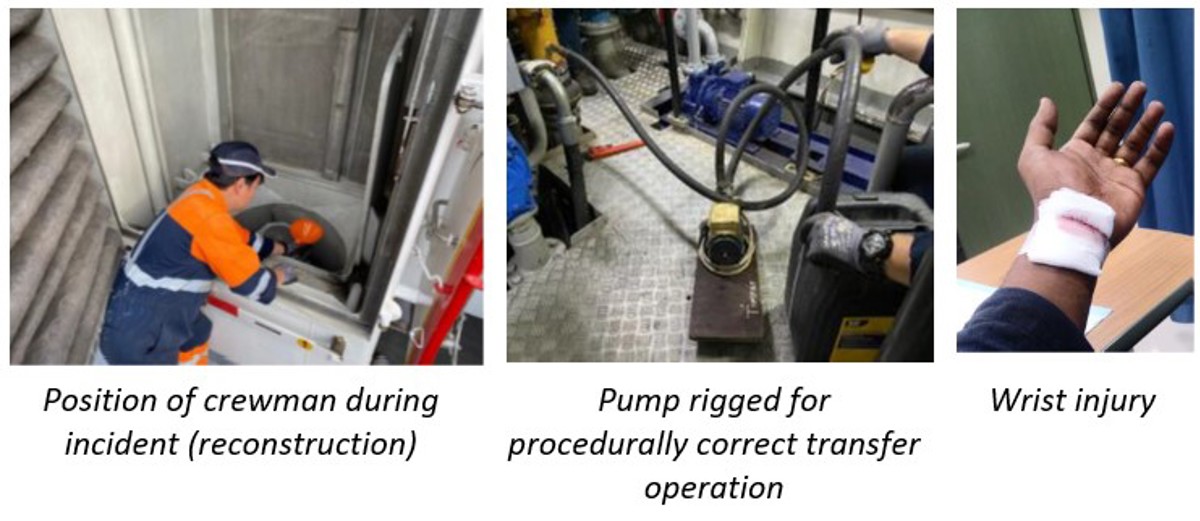

A crewman was injured when there was an uncontrolled and unplanned closure of a fire flap.

The crewman was filling an expansion tank through the engine room ventilation trunking, when the release mechanism for the fire damper was activated unintentionally, causing the fire damper to close on his left wrist, resulting in a wound.

What went wrong?

The injured person filled the expansion tank in a way not detailed in procedures, via the filler cap from above, through the induction fan trunking.

There was a company standard operating procedure for this and he did not follow it.

The procedure for filling/topping up the high-temperature cooling system was via a portable pump with suction direct from a 20/25 litre drum.

This system was in place due to the problematic location of the expansion tank filling cap in the engine room.

What were the causes?

- No physical action was taken on board to locate the pump.

- There was no risk assessment into this nonstandard way of conducting the activity.

- The available transfer system available in the engine room was not used.

- Uncontrolled release of the fire damper.

- The man’s arm was in the line of fire.

Actions

- Ensure no improvisations are replacing designed, approved systems on board. Where not functional, work orders/defects should be documented and if in doubt, assistance sought for clarification or suitable management of change process.

- Risk assessment should be conducted for non-routine tasks.

- Don’t cut corners – crew should be reminded of the dangers of skipping or avoiding steps important to a task.

Members may wish to refer to the following injuries, both arising from taking short-cuts:

- Serious Finger Injury During Valve Installation

- LTI: Finger Injury During Work With Rotating Machinery

See also:

- IMCA HSS001 Guidelines for management of change

- Line of fire (‘Be prepared to work safely’ video)

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.