Near miss: Worker temporarily trapped in confined space

- Safety Flash

- Published on 21 December 2017

- Generated on 25 January 2026

- IMCA SF 32/17

- 2 minute read

Jump to:

On a vessel in a shipyard, a member of the painting team accessed a tank to perform an inspection. Around three hours later, a worker was assigned to close this tank, and this was done – but the painter was still inside.

What happened?

The painter only noticed he was trapped in the tank around 15 minutes after the manhole cover was closed. Fortunately, in less than an hour, personnel assigned to cleaning duties outside the tank’s surrounding could hear knocking sounds from inside the tank and called for assistance to investigate.

The manhole cover was opened, and the painter was able to exit the tank unharmed. Further check-ups with a doctor confirmed no impacts to his health and safety.

What went wrong? What were the causes?

- There was no stand-by person outside the tank.

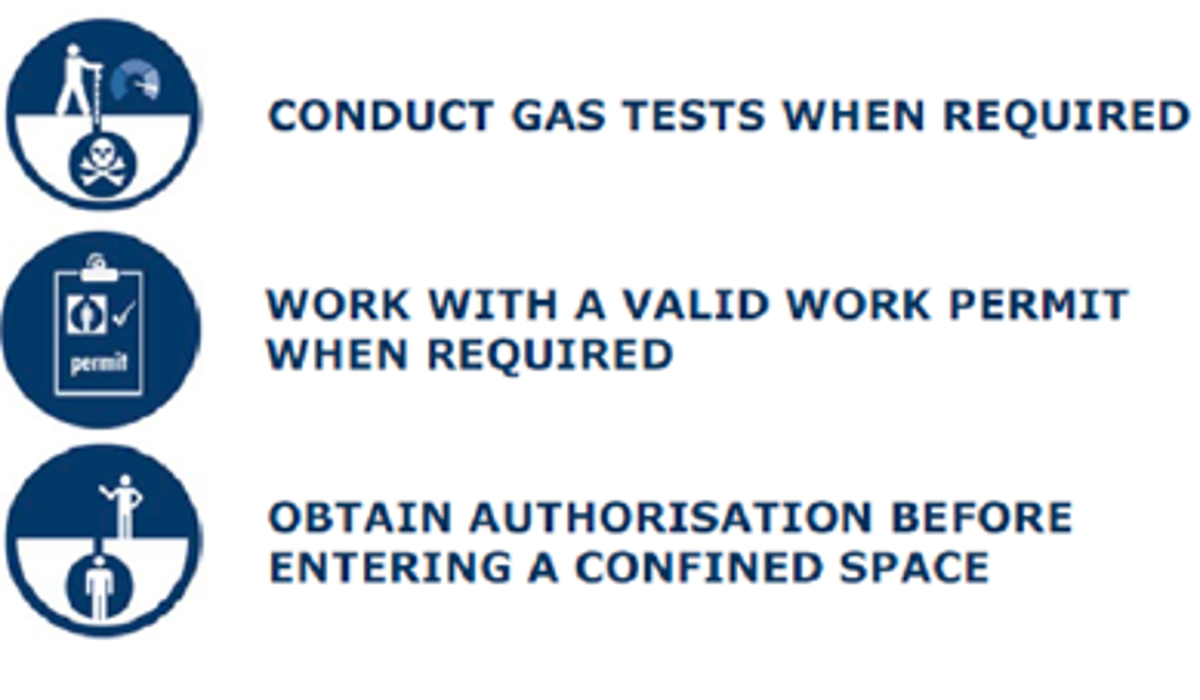

- The painter entered the tank alone, even though the ‘buddy system’ was a practice expected by the shipyard.

- The painter accessing the tank was a team leader and as such, had specific training for confined space entry, but still disregarded the implementation of control measures.

- There was no valid permit to work (PTW) in place for the task, and hence there were no control measures in place, such as safe atmosphere monitoring, ventilation, or illumination.

Lessons learnt

A safety stand-down was led and conducted by the shipyard management with their employees. While this incident happened to shipyard workers during shipbuilding, the lessons learnt are applicable to all IMCA members operations.

This incident is under investigation and further updates may be communicated in future.

Members may wish to review the following IMCA documentation and safety promotional material:

- IMCA HSS032 – Guidance on safety in shipyards

- Short video – Confined spaces: The dangers

- Short video – Permit to work

Related safety flashes

-

IMCA SF 22/15

15 December 2015

-

IMCA SF 14/15

2 October 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.