MSF: Dropped object during cargo discharge operations

- Safety Flash

- Published on 18 November 2021

- Generated on 10 February 2026

- IMCA SF 31/21

- 2 minute read

Jump to:

The Marine Safety Forum (MSF) has published Safety Alert 21-14 relating to a dropped object during cargo discharge operations

What happened?

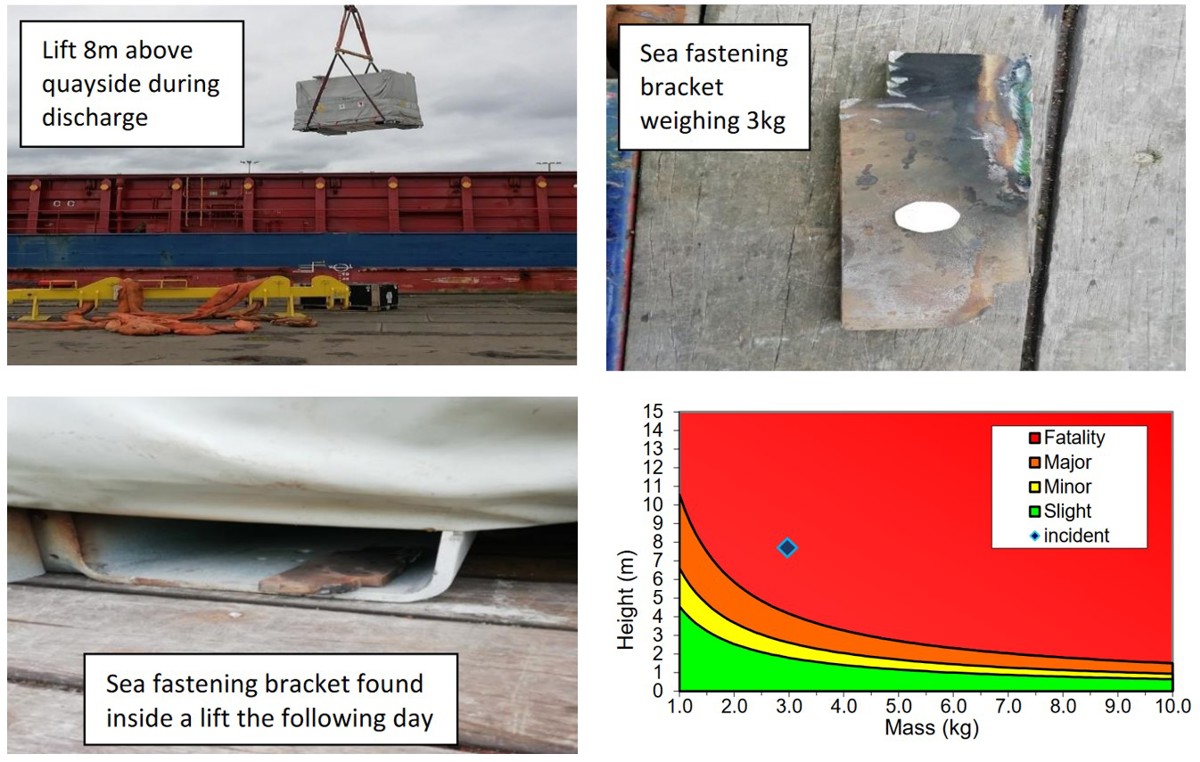

A cargo ship loaded with cargo for the renewables sector was being discharged using a mobile shore crane when a sea fastening bracket weighing about 3 kg fell out of a forklift pocket from a generator that was being offloaded and landed onto a trailer on the quayside.

The vessel was loaded with some 40 heavy lift items, each secured to a steel lifting frame with forklift pockets, each weighing about 80 tonnes, these had all been secured with 8 sea fastenings brackets per lift. The cargo was stowed over 3 decks and the sea fastenings were being burnt off by the ships’ crew and swept up.

During discharge of the lower tween deck a sea fastening was observed to fall from a forklift pocket. The following day another bracket was observed inside a forklift pocket.

A total of 320 brackets had been burnt off. The two missed ones could have resulted in a fatality.

What went wrong?

The MSF’s correspondent noted the following:

- Deck crew were unaware of the requirement to carry out a dropped object sweep of each lift with an emphasis on forklift pockets.

- The lighting in the lower tween deck was poor.

The original MSF report noted that the sea fastenings were being burnt off by the ships’ crew and “diligently” swept up. Obviously not diligently enough…

Actions

- The importance of dropped object sweeps was reiterated to the crew.

- IMCA notes that there may be a lesson here in terms of additional vigilance when doing repetitive work: 320 sea fastenings, and two were missed.

Related Safety Flashes

-

IMCA SF 01/15

16 January 2015

-

IMCA SF 19/14

18 December 2014

-

IMCA SF 18/14

25 November 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.