High potential near miss: anchor brake failure

- Safety Flash

- Published on 21 December 2018

- Generated on 4 February 2026

- IMCA SF 29/18

- 3 minute read

Jump to:

The Marine Safety Forum (MSF) have released Safety Alert 18-25 regarding a potentially fatal near miss incident during dry-docking.

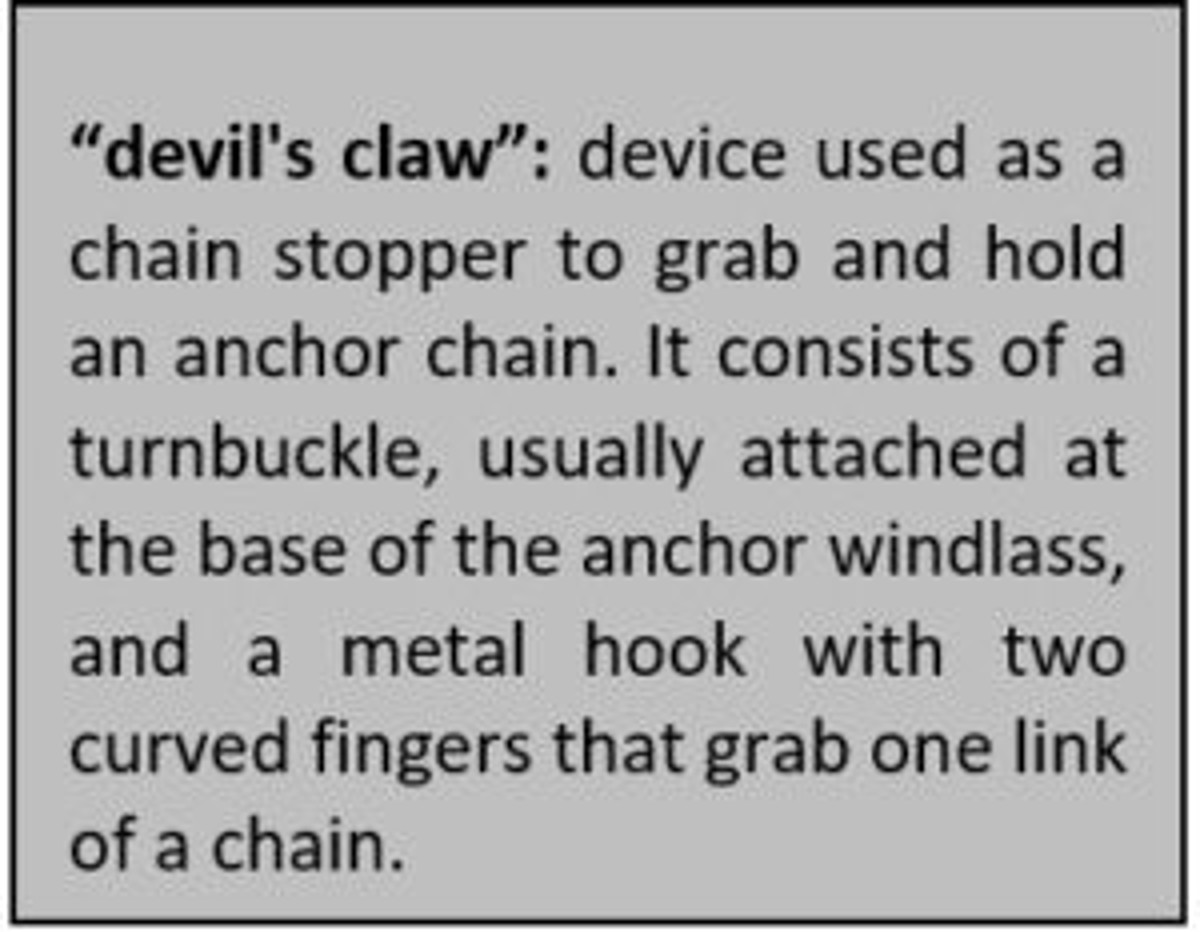

A vessel’s anchors were ranged on the dock bottom for inspection and painting. With the work complete and the vessel due to depart from the dock, the anchors were recovered. Once recovered, the brakes were applied, guillotines on both anchors dropped across, and devils’ claws were engaged. The clutch was disengaged and the brake on the port anchor was tightened to ensure that it was properly applied before finishing the maintenance. At tightening the break, the threaded spindle sheared, completely releasing the break band, meaning that the full weight of the anchor was taken on by the devils’ claw. The weight of the anchor forced the arms of the claw open, allowing the chain to run freely and the anchor and chair to run out to the dock bottom unrestricted.

What happened? What were the causes?

Stripping the brake assembly for investigation revealed that both linkages housing the failed threaded spindle were seized. Lack of rotation in the linkages caused a ‘bending force’ to be applied to the spindle upon tightening the break. Over time, this has caused stress within the spindle, resulting in complete failure.

- Maintenance:

- maintenance on the windlass and associated parts was conducted in line with requirements of planned maintenance system (PMS)

- all parts of the windlass were greased regularly; however, as identified in other mechanical failures, grease from the greasing nipples had not penetrated every part of the equipment, leading to the linkages becoming seized

- Claw:

- the devils claw had been engaged on the anchor cable and tightened, leaving no gap or slack in the lashing

- the two arms of the claw opened as the weight fell upon them, allowing the cable to pass through

- there was no significant corrosion noted on the equipment

- Guillotine:

- the guillotine had not been secured in place when dropped across the cable when the break failed

- because of this, it did not effectively stop the anchor cable running out when the claw failed.

What actions were taken?

- Conduct thorough inspections of moving parts of the anchor windlass – particularly the brake band assembly. All moving parts should be confirmed operational.

- Routine greasing of parts to ensure proper lubrication. When greasing, moving parts should be moved to fill extent of operation to ensure full functionality.

- Any seized or non-operational parts should be freed up at first opportunity.

- Devils claws of the design shown were replaced with wire strops of appropriate safe working load (SWL). Alternative designs are to be reviewed by vessels.

- All anchoring operations should include a check of the area to ensure no other part is placed at risk by the job; check over the side for any small craft at sea or in port. Exclusion zone in the proximity of the anchor during dry dock.

Related Safety Flashes

-

IMCA SF 22/15

15 December 2015

-

IMCA SF 05/15

2 April 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.