LTI: Fingers injured during fender lifting operation

- Safety Flash

- Published on 6 December 2023

- Generated on 16 April 2025

- IMCA SF 28/23

- 3 minute read

Jump to:

A crew member suffered severe injuries to two fingers during fender lifting operations.

What happened?

The injuries occurred while hauling up the webbing slings with a (13mm (half-inch) polypropylene rope so that a Yokohama fender, weighing approx. 415 kg, could be lifted to deck.

The crew member pulled the polypropylene rope to allow him to handle the webbing sling ends and untie the polypropylene rope from the railing.

During this activity the swell caused the rope he was holding to slacken and then come under tension suddenly, and the rope jerked violently and was pulled out of his hand.

He found he had badly injured two fingers of his hand; he was given first aid and then further treatment, and was medevaced ashore.

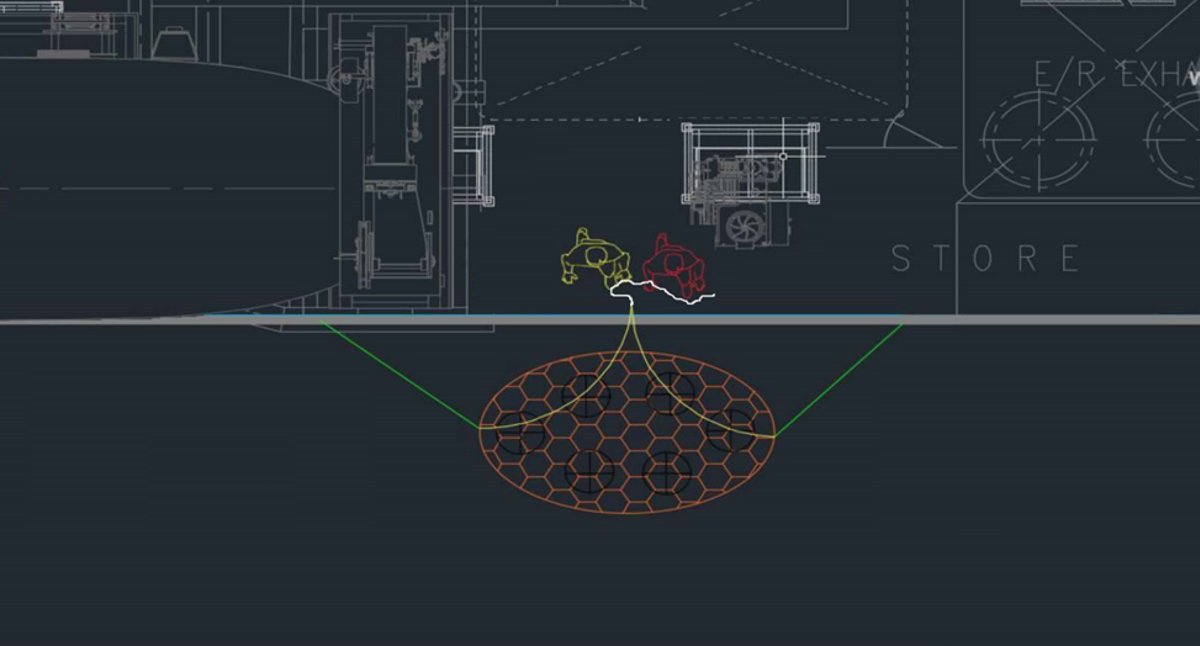

sketch showing position of fender, the webbing strops and short hauling line

Glove prior to removal. Damage to thumb area was pre-existing

Final hand position (re-enactment).

What went right?

- The crew person remained calm during the activity and injury; he went immediately to report the injury to the bridge who called the doctor to the bridge. Onboard medical care was excellent and arrangements were quickly made for medevac.

- The injured person and their co-worker were wearing full PPE as specified in company procedures.

- There was a Permit to Work in place, and a job safety analysis and toolbox talk had been conducted.

What went wrong?

Our member identified the following contributory factors:

- The fender surged a great deal with the swell, this caused the line to jerk in an uncontrolled manner, the rope line jerked out of the workers hand and this was enough to cause the injuries.

- There was a lack of risk perception, the task was seen as routine.

- STOP WORK Authority not used.

- The rope was handled from underneath so that the direction of energy was through the hand (rather than from above which would make release of the rope automatic); this may have contributed to the severity of the injury.

What was the cause?

Our Member summarised the root cause as follows: Procedure and JSA were not robust enough, nor did they adequately cover all steps of the activity. They should have been revisited in light of the changing conditions and the activity should have been stopped and reassessed when the surge of the fender was noted.

Lessons learned and actions

- Although the PPE was inadequate to prevent the injury, substitution with Impact Resistant Gloves, or any other available glove options for this activity, would have been unlikely to have prevented it. The injury was to the palm side of the glove which is not an area where armour or thick padding is traditionally found.

- Watch out for complacency and “task seen as routine”.

- Ensure everyone involved, supervisors and workers, feels empowered to stop the job when conditions change and/or become unsafe.

- PPE cannot always be relied on to prevent injury and is a last line of defence. In this case, our member considers that impact-resistant gloves should have been worn because of the risk of pinch points and entrapment injuries.

- The rope that was tied to the handrail did not have sufficient slack to allow the rope to be easily untied, the snatching could have been avoided either by having extra slack in the rope, or by cutting it.

Members may wish to refer to

-

IMCA SF 09/23

4 April 2023

-

-

IMCA SF 02/23

11 January 2023

-

-

IMCA SF 06/03

1 July 2003

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.