Pipelay technician sustained cut to wrist whilst handling testing equipment

- Safety Flash

- Published on 14 December 2018

- Generated on 7 March 2026

- IMCA SF 27/18

- 2 minute read

Jump to:

During pipelay operations, two non-destructive testing (NDT) technicians were handling a ‘scanner belt’, which is used to connect the automated ultrasonic testing (AUT) scanner to the pipe for testing pipeline welds.

What happened?

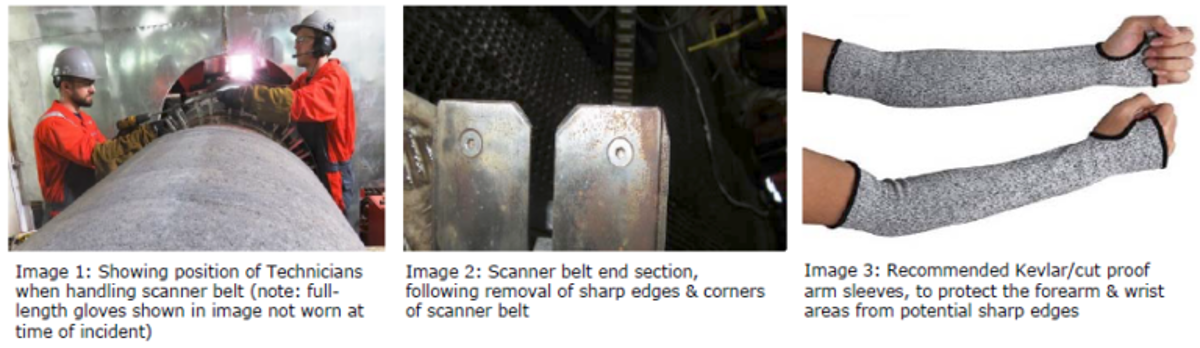

On completion of weld testing, the scanner belt (approx. 10kg) was released by one of the technicians, and it ‘slipped off’ the pipe and made contact with the other technician’s wrist. This resulted in a laceration which required 8 stitches. The injured person was wearing full personal protective equipment (PPE). However, the scanner belt made contact with his wrist which was exposed through the gap between the coverall-sleeve and glove.

What went wrong? What were the causes?

- The equipment design did not account for sharp edges and potential risks during manual handling.

- Personnel involved in the task did not identify the potential for exposure to sharp edges on equipment, and had perceived the task as ‘routine’.

- The injured person did not have clear communication or eye contact with the other technician who released the scanner belt. It was also found that language barriers between the technicians contributed to poor communication.

- The injured person’s coverall sleeve had ‘crept up’ when his arms were reached out, exposing his wrist to contact with equipment.

What actions were taken? What lessons were learned?

- Review of tasks that involve repetitive manual handling of equipment, to ensure that potential sharp-edge hazards are identified and appropriately controlled.

- Communicate safe manual handling techniques for tasks that involve more than one person dealing with equipment at the same time. This should include focus on good communications to prevent loss of control.

- Review of similar tasks and associated PPE controls, to identify potential exposure to forearms or wrists, when arms extending outwards or upwards. Consider use of cut proof arm protection, as shown in images above.

- Reinforce the need for the continual review of controls associated with ‘routine’ tasks, during toolbox talks (TBT) and hazard inspections.

Related Safety Flashes

-

IMCA SF 28/16

18 October 2016

-

IMCA SF 08/16

13 April 2016

-

IMCA SF 02/06

27 February 2006

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.