High potential near miss: Crane part fell to deck

- Safety Flash

- Published on 13 November 2023

- Generated on 13 February 2026

- IMCA SF 26/23

- 2 minute read

Jump to:

During a vessel transit during which the crane was unused in its boom rest, a crew member observed a piece of metal debris lying under the crane boom tip.

What happened?

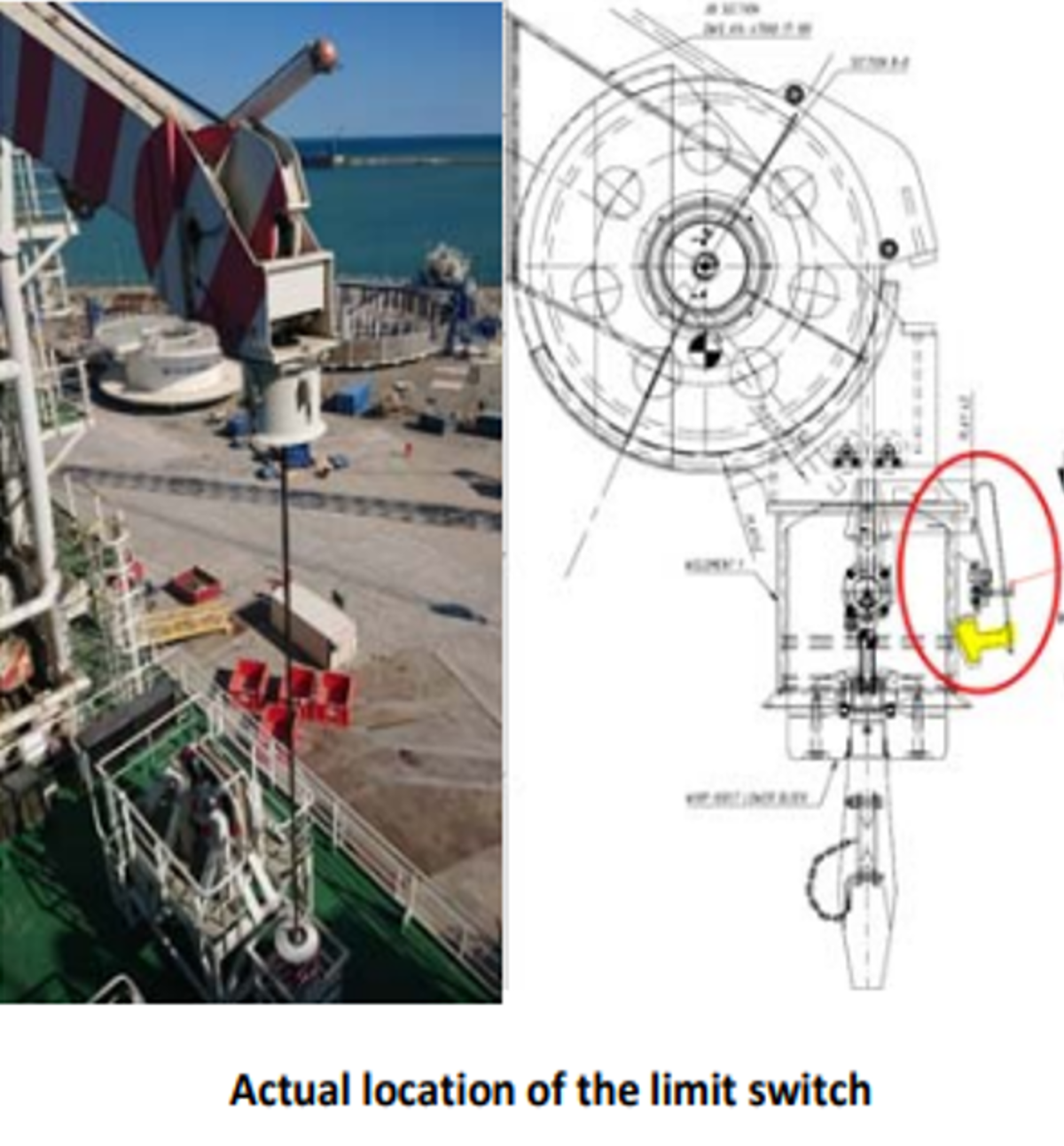

It was discovered that one of the three Crane Whip Line Block Catcher Limit Switches (3.6 kg) had fallen off and had fallen 6.5 m to the deck. There were no injuries.

location of the limit switch at the time it was noticed

What went wrong?

Our Member noted the following:

- Inadequate design verification – the cross‐sectional area of the broken plate was not sufficient to bear the stress applied to the limit switch.

- The bolt spring was acting as a strong point and was creating unbalanced forces on the limit switch plate.

- There was insufficient preventive maintenance or inspection of this area.

What was the cause?

Our Member noted the following:

- The equipment was not being used as it was originally designed.

- The maintenance schedule recommended by the crane manufacturer, was not adequate.

Lessons learnt

- Testing of the limit switches during a third-party thorough examination, though providing satisfactory results, could prove misleading.

- Complicated access to the boom tip does not allow proper inspection of these and other integrated elements of this 900T crane.

Actions

- Work with the crane manufacturer on a new design of the limit switch plate.

- Amend preventive maintenance schedule and inspection program to include more frequent assessment.

- Look at other vessel cranes for any signs of potential weak points on the limit switches.

Related safety flashes

-

IMCA SF 05/20

13 February 2020

-

-

IMCA SF 05/20

13 February 2020

-

-

IMCA SF 21/17

23 August 2017

-

-

IMCA SF 16/16

27 June 2016

-

IMCA SF 21/15

7 December 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.