Pin from crane block sheave guard fell 25 m

- Safety Flash

- Published on 20 October 2017

- Generated on 13 January 2026

- IMCA SF 26/17

- 2 minute read

Jump to:

A member of UK Step Change in Safety reports an incident in which a main block sheave guard came loose from the main crane block and fell approximately 25 m to the deck below.

What happened?

The incident occurred when a container was being repositioned on a laydown area. The crane was being used, utilising the whip line and a pennant. The crane main block was not used due to the low weight of the load.

During the lift, a member of the deck crew heard a loud noise. On investigation, he found that the securing pin from a main block sheave guard had come loose, and had fallen to deck. Crane operations were immediately halted and the crane main block was brought to deck level for inspection.

The fallen part weighed 0.8 kg and fell 25 m; it landed 2 m from a member of the deck crew. This could have been a potential fatality on the DROPs calculator.

What went wrong? What were the causes?

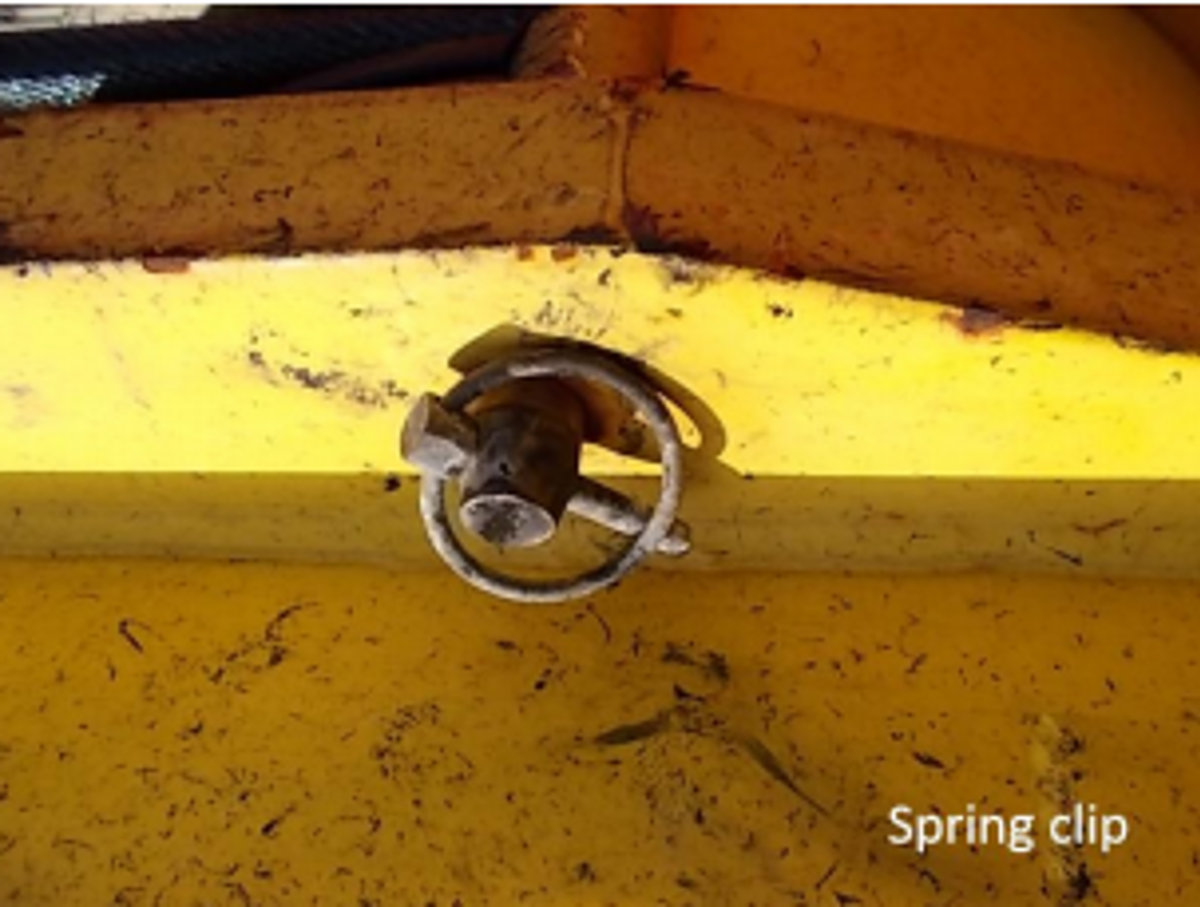

The sheave guide was secured by a spring clip. The crane block was supplied with this spring clip configuration. It cannot be determined if the clip had failed or was not installed correctly.

What lessons were learnt? What actions were taken?

The spring clip on the sheave guide was removed and replaced by a bolted configuration. All cranes in the fleet were inspected to ensure the same configuration was not present; if it was, it was corrected.

Suppliers were informed of incident to ensure they no longer supply blocks with this configuration. Planned maintenance tasks were amended to ensure checks are carried out on condition of sheave guards.

The Step Change in Safety ‘Safety moment’ can be found at stepchangeinsafety.net.

Related safety flashes

-

IMCA SF 16/16

27 June 2016

-

IMCA SF 10/15

16 July 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.