Near-miss: Release of trapped pressure after ROV dive

- Safety Flash

- Published on 6 October 2016

- Generated on 7 March 2026

- IMCA SF 26/16

- 2 minute read

Jump to:

A Member has reported an incident in which there was an unplanned release of trapped pressure from part of the tooling frame under an ROV.

What happened?

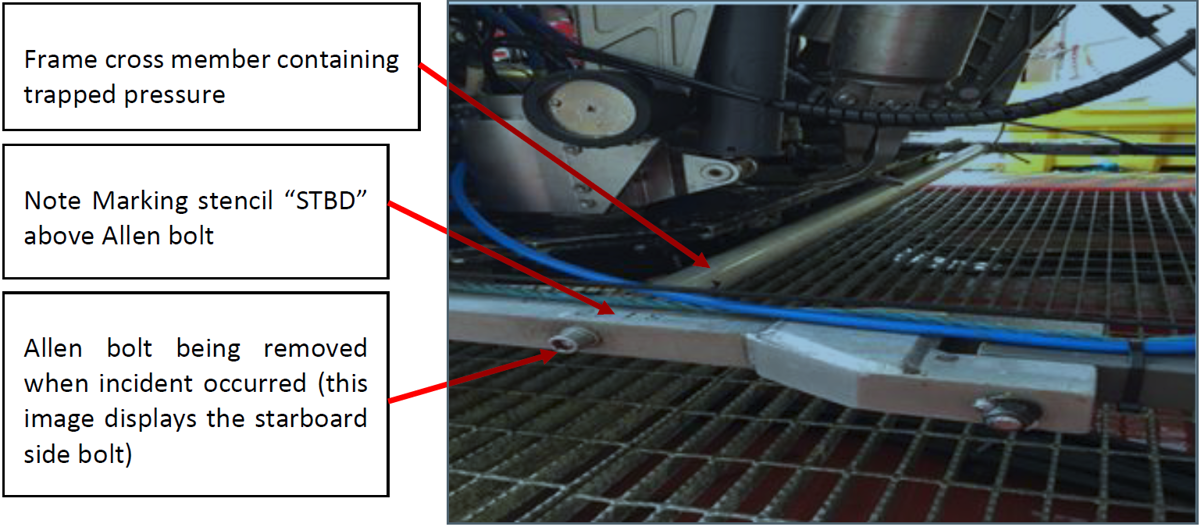

The incident occurred when it was noted that the frame was not deploying correctly and was slightly twisted. Upon investigation the coil mounting frame had been fitted upside down. The crew began to remove the cross member using an Allen key to separate the frame into two sections for removal and to ease the handling during the turning over portion of the task.

Upon the first quarter turn of the port side Allen bolt, a hissing noise was heard. The supervisor immediately evacuated the area and had it barriered off.

The system was left to bleed down naturally. The risks of the job were re-assessed and additional personal protective equipment (PPE) was identified for further work in removing the frame.

Causal factors:

- The potential for trapped pressure had not been identified.

- The frame had been incorrectly fitted.

The following actions were taken:

- An engineering solution was identified to prevent possibility of trapped pressure – holes drilled in cross-member.

- Safety flash issued.

- Other similar systems checked and modified as required.

- Clear markings applied to ensure correct frame orientation.

Related Safety Flashes

-

IMCA SF 07/14

13 May 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.