High potential: spontaneous opening of hydraulic release shackle (HRS) pin

- Safety Flash

- Published on 17 December 2024

- Generated on 29 April 2025

- IMCA SF 24/24

- 3 minute read

Jump to:

During lifting operations on a vessel, a hydraulic release shackle pin opened on its own.

What happened?

The incident occurred when the main crane auxiliary block was connected to the flare lifting slings, hydraulic hoses, and Hydraulic Release Shackles (HRS). A blue colour coded HRS spontaneously opened from its original secured position and dropped approx. 4-5 meters from its position and was left hanging from the hydraulic hose. An “All STOP” was called. No-one was harmed.

Broken connection

Bent connection plate

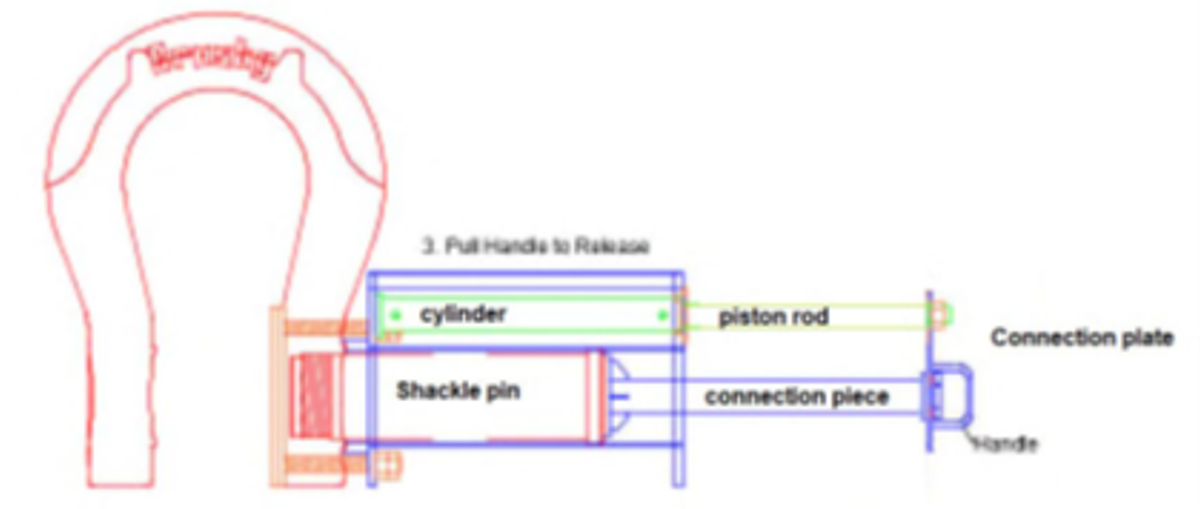

Diagram of the Hydraulic Shackle set-up

What went wrong?

After rigging back the ‘blue shackle’ to its position and performing function tests to this same shackle and the other 3 HRS units, it was then identified that the ‘yellow colour coded’ HRS was damaged (broken piston) and further damage was identified to the initial ‘blue colour coded’ HRS (bent piston rod). The operation was subsequently abandoned.

Our member’s findings included:

- There was some complacency: assumptions and decisions were made without full compliance or verification against requirements (manufacturer manual, company procedures, etc.).

- The way the job was to be done, was changed before it started, without any form of Management of Change process taking place.

̶ The method chosen was to do set up the hydraulic release shackle (HRS) using vessel crane Hydraulic Power Unit (HPU). There was evidence that the procedures and manufacturer’s requirements for operating the vessel crane Hydraulic Power Unit were not adequately complied with. - There was evidence that some crew involved did not comply with and were not even aware of, certain other procedures and documentation pertaining to this work.

- There was no operational risk assessment, nor task risk assessment for the change of set-up, and general non-compliance with procedures.

- An opportunity was missed to have detailed review of the risks and controls for the HRS system and its compatibility to the vessels crane hydraulic system.

Lessons

· Communication: there was less than effective communication between the main parties involved in this operation.

· Remain curious: take nothing for granted. Keep questioning all aspects of what may go wrong. Ask “What if?” Dedicate time to go through all potential risks to consider and implement adequate mitigation controls.

· If in doubt, STOP the JOB!!

· Addressing change: ensuring we respond to the need for change in an open-minded and positive way.

Actions

· Ensure all decisions made regarding changes to critical equipment set up are conducted in line with manufacturer requirements.

· Conduct general review for similar equipment across projects and worksites.

Related Safety Flashes

-

IMCA SF 16/16

27 June 2016

-

IMCA SF 02/15

5 February 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.