Hydraulic Oil Leak to Sea from Downline Fitting

- Safety Flash

- Published on 1 November 2022

- Generated on 13 February 2026

- IMCA SF 24/22

- 2 minute read

Jump to:

During decommissioning, cutting work was being conducted using a diamond wire saw.

What happened?

A third-party supplier’s technician noticed a sudden drop in pressure, and it was discovered that 100 litres of hydraulic oil had been released to sea.

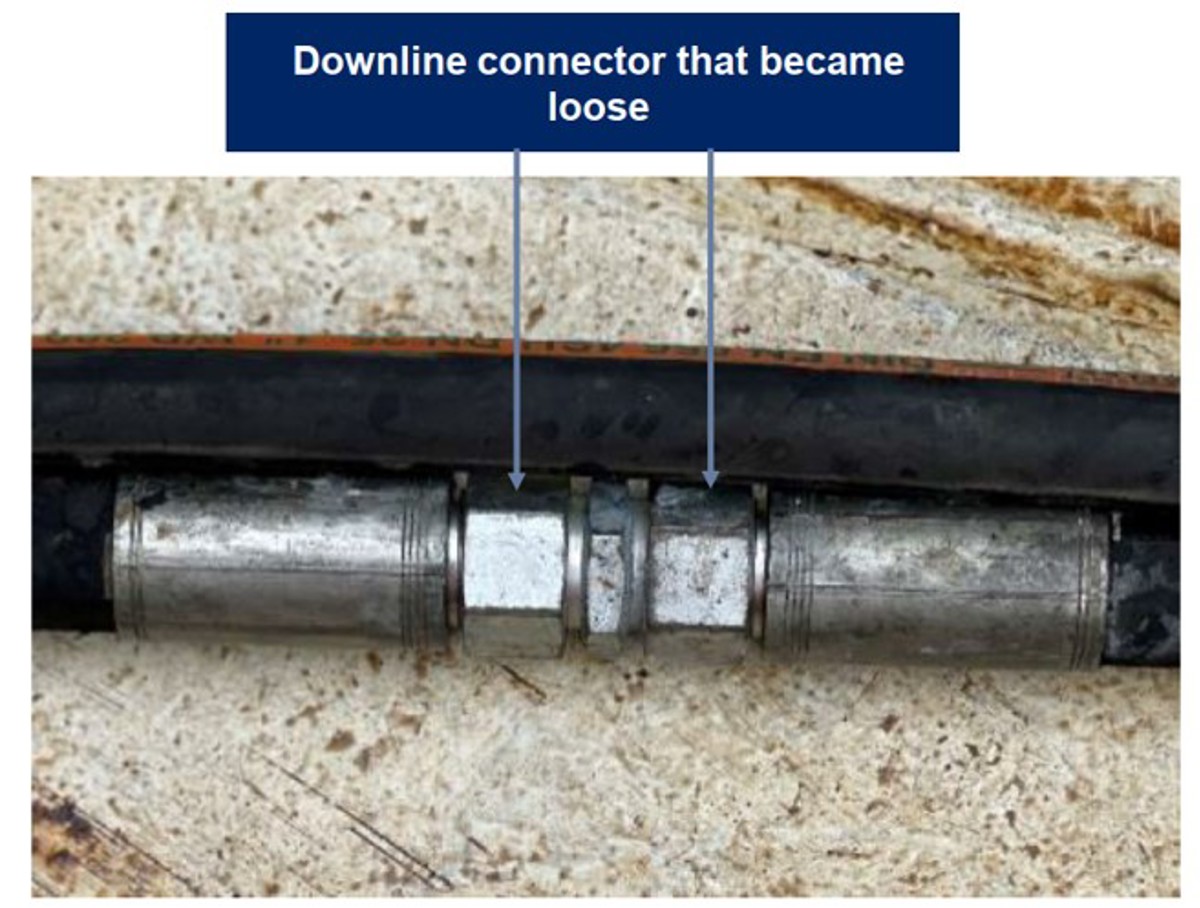

The downline was disconnected, recovered to deck and inspected. The leak was coming from a BSP fitting 40m from the diamond wire saw connection point.

Before the incident, the system had been deployed following deployment checks using a dedicated form for hydraulic checks. The downline was in a “figure 8” on deck and subsea as per procedure and risk assessment.

BSP fitting which came loose

What was the cause?

Our member identified the following:

- Immediate Cause: the fittings became slack: It is not known when the fitting slackened. It is suggested that a combination of handling on deck, energising and de-energising were contributory factors.

- Underlying Cause: checks were omitted: Fittings were not checked for tightness when overboarding the diamond wire saw and downline.

- Root Cause: the checklist used did not prompt the check of all fittings for tightness, only visual checks.

Our member took the following actions:

- Added additional supports on fittings attached to the tugger over and above existing controls.

- Ensured that physical checks for tightness were conducted.

- After a review of feasibility, the bight of the hydraulic hose was removed.

- Checklist was updated to include checks for the tightness of fittings.

- Incident was shared with other users of similar equipment.

Related Safety Flashes

-

IMCA SF 15/18

20 July 2018

-

-

IMCA SF 10/15

16 July 2015

-

IMCA SF 16/20

22 May 2020

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.