Serious hand injury during mooring operations

- Safety Flash

- Published on 3 October 2023

- Generated on 23 January 2026

- IMCA SF 23/23

- 2 minute read

Jump to:

A dock worker suffered a serious hand injury during mooring operations.

What happened?

The incident occurred as the vessel was prepared for departure from the berth.

The mooring foreman signalled the team to let go, keeping one line on the bollard. The injured person grabbed the rope at the end of the eye near the area of the splice and began to remove it from the bollard.

Halfway through removing it from the bollard, the rope suddenly tightened, causing the eye of the rope to catch onto the side of the bollard while his right hand got stuck in between two ropes.

The injured person was able to pull out his hand from the trapped gloves and shout for help, before receiving first aid.

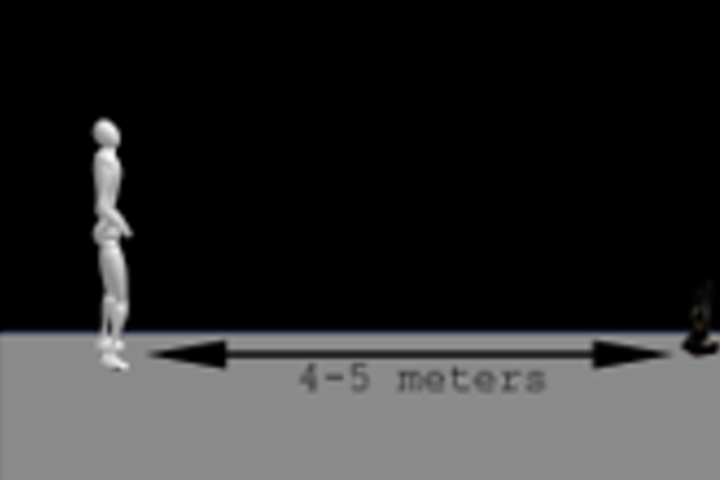

Position of injured person (IP)

Signalling to vessel crew to slack while approaching the line

Grabbing the rope at the end of the eye

Hand caught between the two ropes

What went wrong?

- There was a lack of planning, a lack of risk assessment, a lack of forethought: the injured party put their hand in the line of fire.

- Insufficient slack was provided in the rope when the dock worker attempted to grab the spring line from the bollard. As the ship’s crew attempted to slack the spring line, tension mounted and caused the rope to tighten on the vessel’s winch.

- The absence of a messenger or tail line attached to the ship’s mooring lines.

Lessons learned

- Stop and think before acting – take the time to think things through.

- Keep your hands and fingers out of the line of fire.

- Be ready to stop the job if someone else is looking as though they are putting themselves or others at risk.

Related safety flashes

-

IMCA SF 09/23

4 April 2023

-

-

IMCA SF 22/22

3 October 2022

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.