NOPSEMA: Person injured in chain hoist incident

- Safety Flash

- Published on 19 August 2021

- Generated on 25 April 2025

- IMCA SF 23/21

- 2 minute read

Jump to:

The National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) of Australia has published Safety Alert #73 relating to an incident on an offshore facility where members of the workforce were impacted during a lifting operation. One member of the workforce was injured and transferred onshore for medical treatment.

What happened?

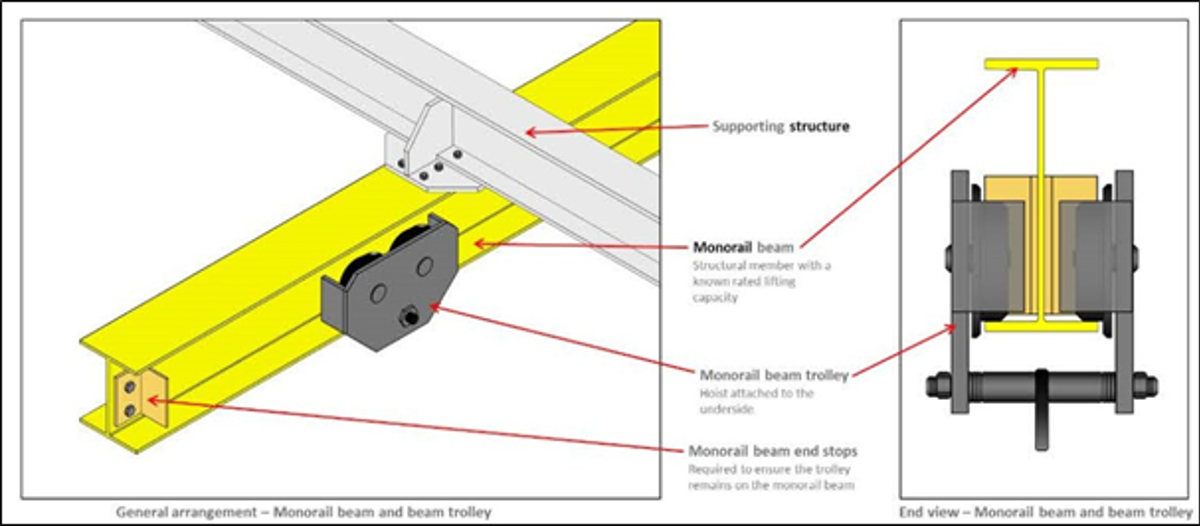

The incident involved a monorail hoist dropping a 500kg piping spool (including ancillaries) when its beam trolley, chain hoist and suspended load overran the end-stop.

What went wrong?

NOPSEMA’s preliminary findings identified that

- The monorail hoist was not fit for purpose, specifically the monorail end stops and beam trolley width.

- The beam trolley had been modified outside of management of change processes.

- The lift plan was not followed, resulting in unsafe operation of the monorail hoist.

NOPSEMA reminded duty holders that “all lifting equipment must be designed, installed, inspected, and maintained in accordance with the relevant standards and by a competent person.”

Actions

NOPSEMA noted the following:

- Monorails, including their end stops and attachment to supporting structures, must be designed, installed, and inspected in accordance with the requirements of the relevant standards by a competent person.

- Serially produced lifting equipment, including monorail beam trolleys, must not be modified from the original equipment manufacturer design.

- Appropriate lifting equipment must be selected for use for the specific lifting application;

- Monorail hoist systems are designed for the vertical lifting/lowering and lateral transfer of loads. Monorail hoists must not be used for dragging loads and non-vertical lifting as it may result in a failure of the monorail beam/beam trolley/end stops and/or the dropping of the load.

Related Safety Flashes

-

IMCA SF 20/21

22 July 2021

-

-

IMCA SF 12/20

31 March 2020

-

-

IMCA SF 15/13

23 September 2013

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.