Lifting complex loads – offloading third party equipment

- Safety Flash

- Published on 19 August 2021

- Generated on 29 April 2025

- IMCA SF 23/21

- 3 minute read

Jump to:

While being lifted off a vessel, a cherry picker (a movable hydraulic crane with a railed platform used to raise or lower personnel) tipped over, causing minor damage to the vessel bulwark.

What happened?

The incident happened when crew were in the final hour of preparing the vessel for departure from port.

A rented cherry picker which had been used on the vessel for maintenance work during the port call, was being offloaded.

After connecting the dedicated rigging provided by the supplier, the crane operator came up on the load in preparation for the lift.

The cherry picker tilted towards its counterweight and came to rest against the vessel bulwarks causing minor damage. An All Stop was called, with the bridge and captain informed.

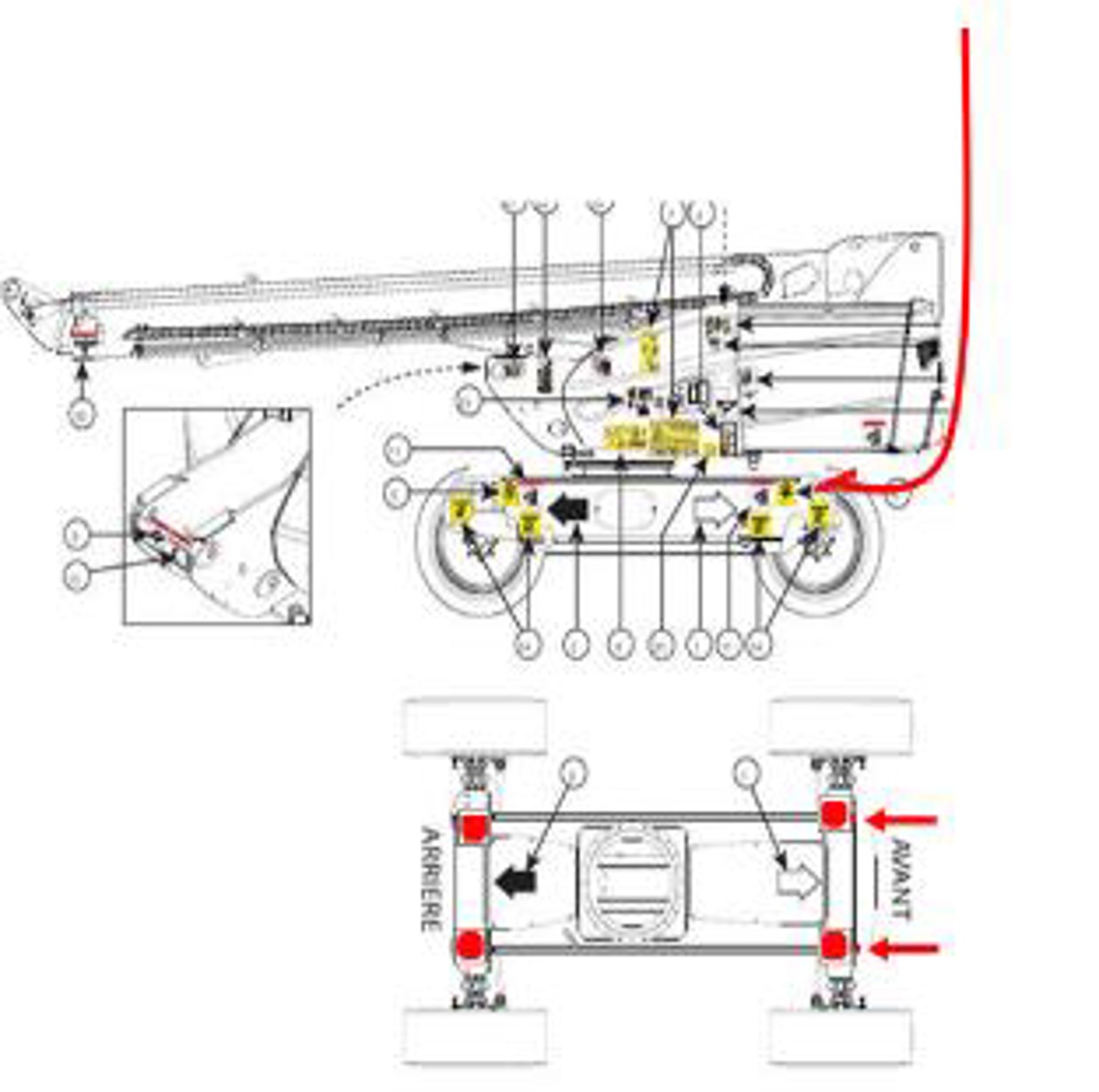

Extract from operations manual

Cherry picker incorrectly rigged

Correct rigging arrangements

What went wrong?

- Inadequate handover, inadequate communication:

- The cherry picker had been lifted on board by vessel personnel who had subsequently crew changed out before the maintenance works were finished.

- The initial lift detail and information was not effectively communicated to the oncoming team.

- When the cherry picker was brought on board, the lift plan took no account of the condition of the unit or the correct rigging required to lift it safely.

- The cherry picker had been lifted on board by vessel personnel who had subsequently crew changed out before the maintenance works were finished.

- The information in the cherry picker operations manual did not address how to safely lift such a unit.

- The rigging arrangement for the unit created a clash with the lift points and the counterweight. This led the lifting team to consider that the correct set up for the lift required the boom to be placed at a 90° offset therefore removing the clash.

Actions

- Specific to lifting cherry pickers:

- Develop a specific lift plan for cherry pickers. The lift plans should be readily available and refer to specific guidance from the manufacturer’s manual.

- Ensure correct documentation including operations manuals and information relating to safe lifting operations is available from third-party plant and equipment vendors.

- Require dedicated and certified rigging to accompany the rental.

- Discuss this issue with logistics and supply chain personnel and with port agents and suppliers, to safeguard the provision of equipment, information and documentation relating to the hire of plant and equipment.

- Develop a specific lift plan for cherry pickers. The lift plans should be readily available and refer to specific guidance from the manufacturer’s manual.

- Where crew changes may impact operations, plans should be in place to support effective handover of key information such as lift plans.

- Lifting requirements, particularly for complex objects, should be thoroughly understood and confirmed by all persons involved.

- Management and supervisors should continue to support “Stop the Job” with their teams.

IMCA notes that before use of third-party rigging equipment, there should be thorough examination by a competent person.

Members may wish to refer to:

- IMCA HSS019 Guidelines for lifting operations

Related Safety Flashes

-

IMCA SF 17/19

16 July 2019

-

-

IMCA SF 09/19

3 May 2019

-

-

IMCA SF 09/18

24 April 2018

-

-

IMCA SF 23/16

13 September 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.