LTI: fractured finger during anchor handling

- Safety Flash

- Published on 3 October 2022

- Generated on 7 March 2026

- IMCA SF 22/22

- 3 minute read

Jump to:

A crew member suffered a serious finger injury when he got his finger trapped.

What happened?

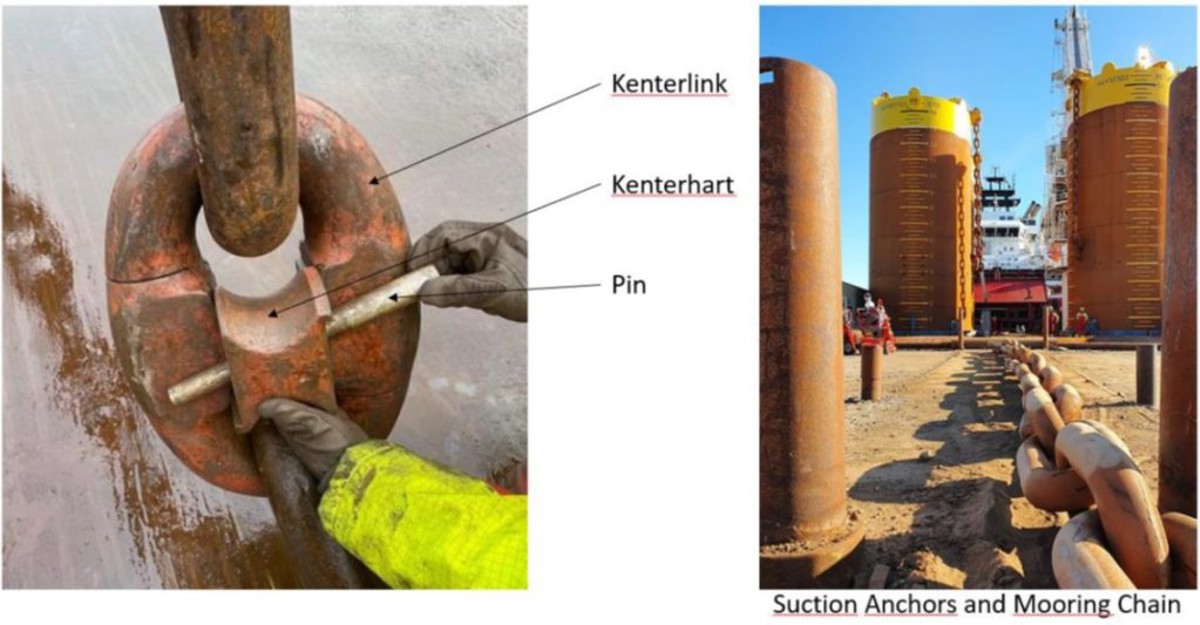

The incident occurred when a vessel had been installing mooring elements, suction anchors and mooring chain. Whilst handling chain, the injured person got his finger squeezed when loosening a bolt (pin) from the central part of a Kenter link (Kenter heart). He went to see the medic onboard and was treated, but was unable to do any practical work on deck the next day. When the vessel arrived back in port he was sent for X-rays, which revealed that the fingertip was fractured. He was then sent home on sick leave.

What went right?

The injured person was just hired and had a positive learning attitude to the job, and felt that he was well taken care of and safe. There were personnel working around him on deck and he was a part of a “buddy” system.

What went wrong?

The injured person was sitting on deck hitting the Kenter heart down to drive out the pin. The pin is a conical shape, and so it must be done the correct way or else it will be driven firmer into the Kenter heart. If this is done the correct way, the pin comes out easily. While he was hitting the heart with the pin down to a hard surface the wrong way, it didn’t loosen but slipped and his finger got squeezed/pinched between the deck/chain and Kenter heart.

What were the root causes?

Lack of training & knowledge – the injured person had previous experience on deck on various vessels, but was new to this vessel and anchor handling operations. While he had received training and he was supervised working on the aft deck. He did not know about the conic shape of the pin in the Kenter heart.

Insufficient supervision – whilst there were personnel working around him on deck and he was a part of a “buddy” system, he was not being overseen at the time of the incident;

Lack of effective risk assessment – the risk assessment for the specific job was done in the beginning of the campaign before the injured person was onboard. The team did not effectively perceive the risks in the situation and the injured person did not stop to get advice from his colleagues.

Short IMCA videos

Are YOU prepared to work safely?

Lessons

- A higher focus on training and supervision of inexperienced or new personnel.

- Communicate incident effectively: New employees represent an increased risk of injuries and need special attention during their first shifts and time onboard. Increased activity in general, also means increased number of new employees onboard the vessels.

- Could impact gloves be helpful in some operations on deck?

Related Safety Flashes

-

IMCA SF 22/20

24 July 2020

-

-

IMCA SF 32/17

21 December 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.