Serious Injury from Rotating Winch

- Safety Flash

- Published on 25 September 2018

- Generated on 7 March 2026

- IMCA SF 22/18

- 2 minute read

Jump to:

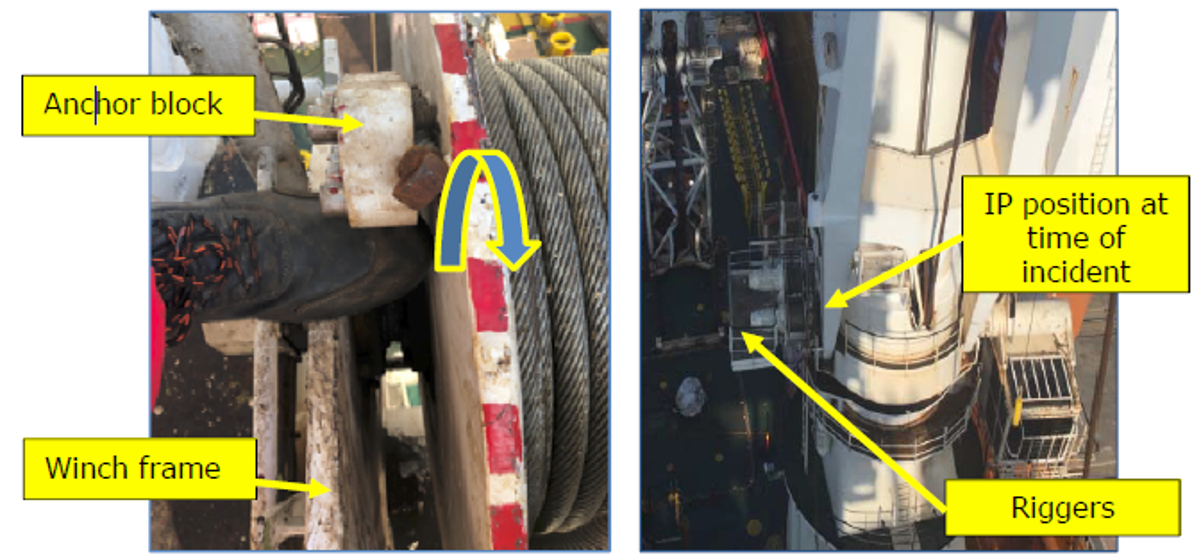

A person involved in spooling a wire onto the main crane forward tugger winch drum suffered a serious foot injury.

What happened?

To facilitate the operation, he positioned himself in a restricted space inboard of the winch and opposite to the supporting riggers on the crane tugger platform. When he decided to leave this location, he placed his left foot on the winch frame to help step over a protrusion. This resulted in his foot being placed directly into a line of fire position, extending beyond the handrail. The anchor block, fitted to the outside of the still rotating winch drum, struck the extended boot which resulted in all five toes being amputated.

What went wrong? What were the causes?

Our members’ findings were that:

- The task risk assessment (TRA) was inadequate for the work and did not recognise hazards associated with rotating equipment during the spooling operation.

- The TBT did not discuss positioning for the personnel involved in the task, and did not emphasise the rotating block as a hazard.

- The rotating anchor block was unguarded as it was thought to be safe and barriered by the handrail.

- Safer options were available to the work team but not taken.

- There had been no time pressure to complete the task.

Our member took the following actions:

- Conducted a ‘hazard hunt’ on winches to identify further potential line of fire hazards.

- Re-assessed the effectiveness of the existing safety controls (safe use of work equipment), barriers, implemented required improvements and reporting findings back to shore-side management.

- Reinforced importance of specific risk assessments, effective TBT preparation and delivery for every activity, and the importance of last-minute risk assessment at work-site to ensure that all hazards have been identified prior to work starting.

- Reiterated importance of ‘Stop Work Authority’.

Members may wish to refer to:

- Toolbox talks (‘Be prepared to work safely‘ video)

Related Safety Flashes

-

IMCA SF 13/17

2 June 2017

-

-

IMCA SF 18/14

25 November 2014

-

IMCA SF 03/00

1 July 2000

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.