Crewman badly scalded during tank cleaning

- Safety Flash

- Published on 1 September 2016

- Generated on 4 March 2026

- IMCA SF 22/16

- 2 minute read

Jump to:

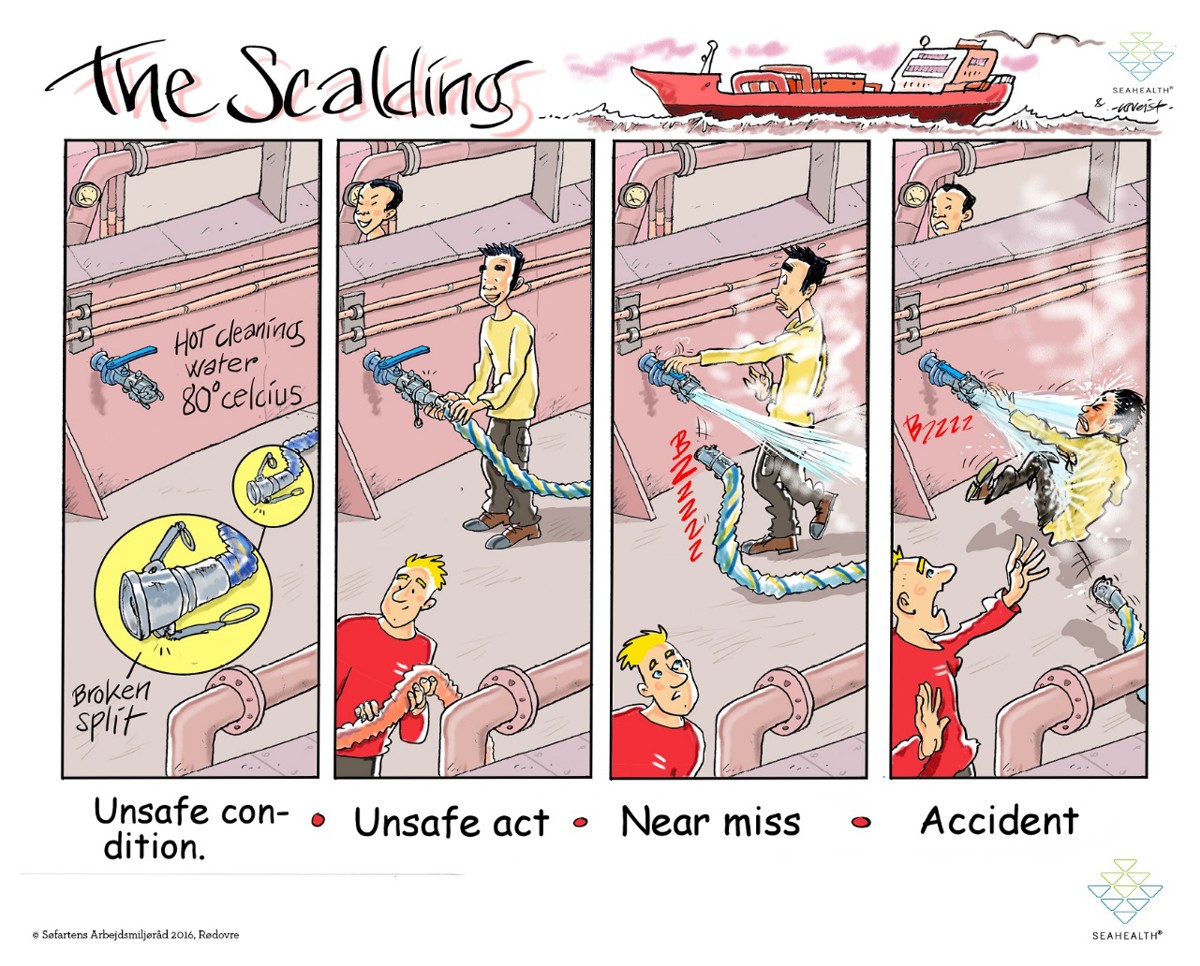

Seahealth.DK has circulated a report of an incident during tank cleaning in which a crewman was badly scalded, receiving first and second degree burns over a third of his body.

What happened?

The incident occurred during hot water cleaning on lube oil tanks, when cleaning machines were exchanged between sequences of cargo tanks. When changing sequence, the tank cleaning hose, when pressurized, opened up and hot sea water released freely from the line. The injured party was positioned alone right in front of the hydrant and not expecting the failure. None of the crew saw what caused the failure, but they noticed steam clouds from hot water coming off the hydrant and the injured person next to the hydrant.

Another crewman jumped towards the valve to close it down. The injured person was sitting down under shock and not responding. He was helped to undress and put under running freely safety shower to cool down.

Our member’s investigation noted the following:

- The personal protective equipment (PPE) used for this operation were boiler suits, safety shoes, safety goggles, helmets, safety gloves, all according to company procedures.

- The plan for the tank cleaning had been discussed and a risk assessment had taken place as part of the procedures.

- The sequence in which the tanks were to be cleaned had been agreed before preparations started.

- Tank cleaning hoses for the next sequence of cleaning were prepared in advance and connected to the system during the previous sequence.

- The cleaning temperature was approx. 80°C.

- At the time of the incident six crew members were working on deck: Bosun, pumpman, two AB’s and two seamen.

- Crew were standing by different tanks opening and shutting down appropriate tank cleaning machines.

Immediate cause

Investigation revealed that the most likely cause was that the securing mechanism/locking mechanism for the camlock coupling was either defective or not properly locked, leading to the coupling to break off when pressure was applied. When the hose was found, after it had gone off the connection point, one of the locking handles was found broken off; the shaft missing and the gasket was found on the deck.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.