Paper shredder – explosion

- Safety Flash

- Published on 29 August 2023

- Generated on 13 February 2026

- IMCA SF 21/23

- 2 minute read

Jump to:

There was a small explosion in an office paper shredder.

What happened?

The explosion happened after the blades were lubricated to ensure that the paper shredder cutting blades ran smoothly and to prevent paper jams after a period of intensive use.

The method adopted, was to spray WD-40 silicone lubricant onto a sheet of paper, switch on the machine and immediately feed the lubricated sheet through shredder blades.

The heat generated during the shredding process or a spark from the internal motor ignited the WD-40 vapours, which had accumulated inside the shredder collection bin.

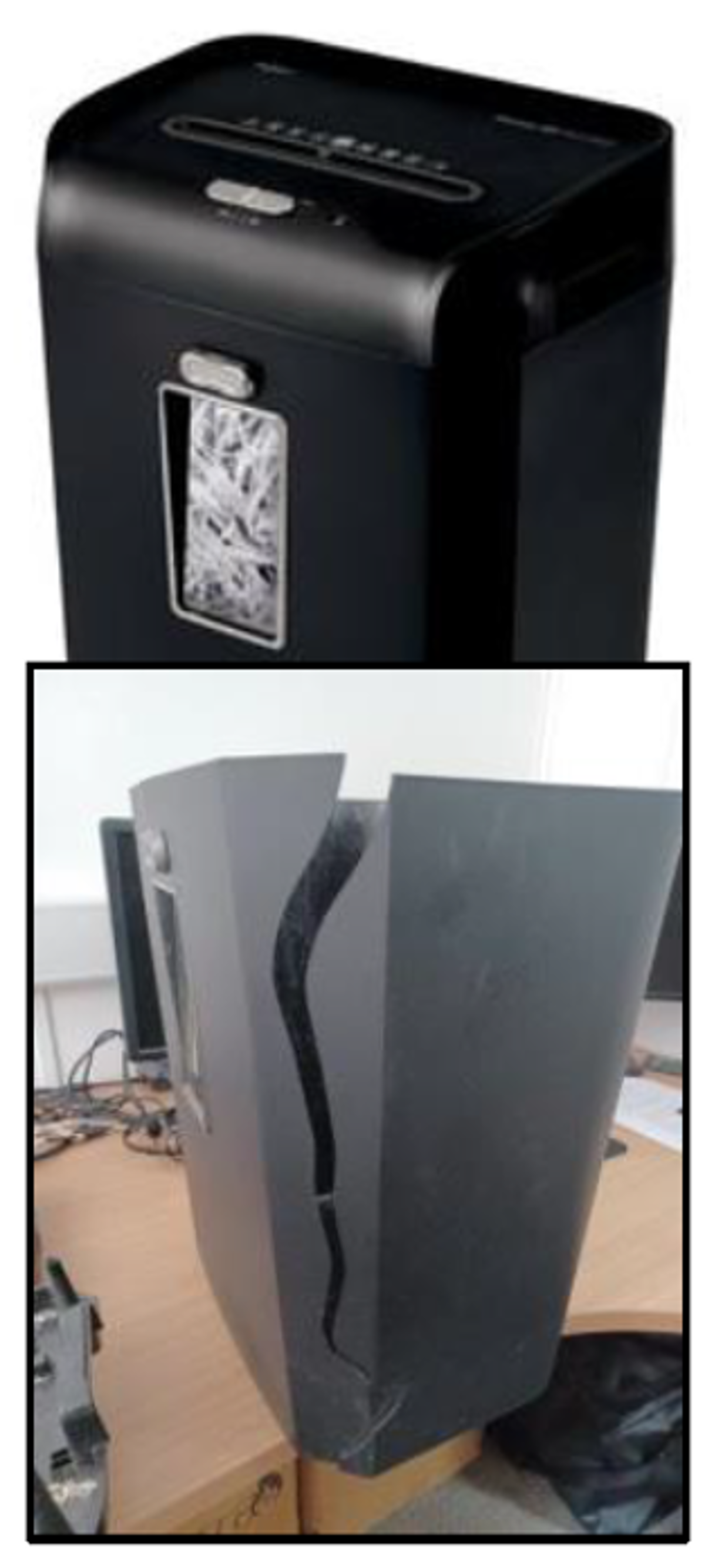

This resulted in a small explosion. No-one was harmed; the paper shredder’s plastic bin was destroyed.

before and after views of the paper shredder

What went wrong?

WD-40 silicone spray is classified as a flammable product.

- The office staff did not appreciate the risks associated with using a flammable product.

- The WD-40 silicone lubricant safety data sheet had not been adequately reviewed.

- The use of WD40 silicone lubricant had not been properly risk assessed.

Lessons learned and actions taken

- The paper shredder operating instructions state that “proprietary lubrication sheets” should be used to lubricate the shredder blades – appropriate paper shredder lubrication sheets were purchased.

- Our member reviewed:

- how hazardous substances are selected, used and managed on site.

- manufacturer’s instructions and maintenance requirements for these products, with appropriate safe systems and precautions implemented.

- how hazardous substances are selected, used and managed on site.

- Read, understand and follow manufacturers’ instructions!

- Be aware of the risks of flammable products.

Related Safety Flashes

-

IMCA SF 28/22

13 December 2022

-

IMCA SF 15/20

5 May 2020

-

-

IMCA SF 04/09

2 April 2009

-

IMCA SF 01/03

1 January 2003

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.