Dropped object near miss – hammer dropped from scaffolding

- Safety Flash

- Published on 23 August 2017

- Generated on 25 February 2026

- IMCA SF 21/17

- 2 minute read

Jump to:

A hammer weighing 1.1 kg was inadvertently dropped from height and fell over 12 m to the deck.

What happened?

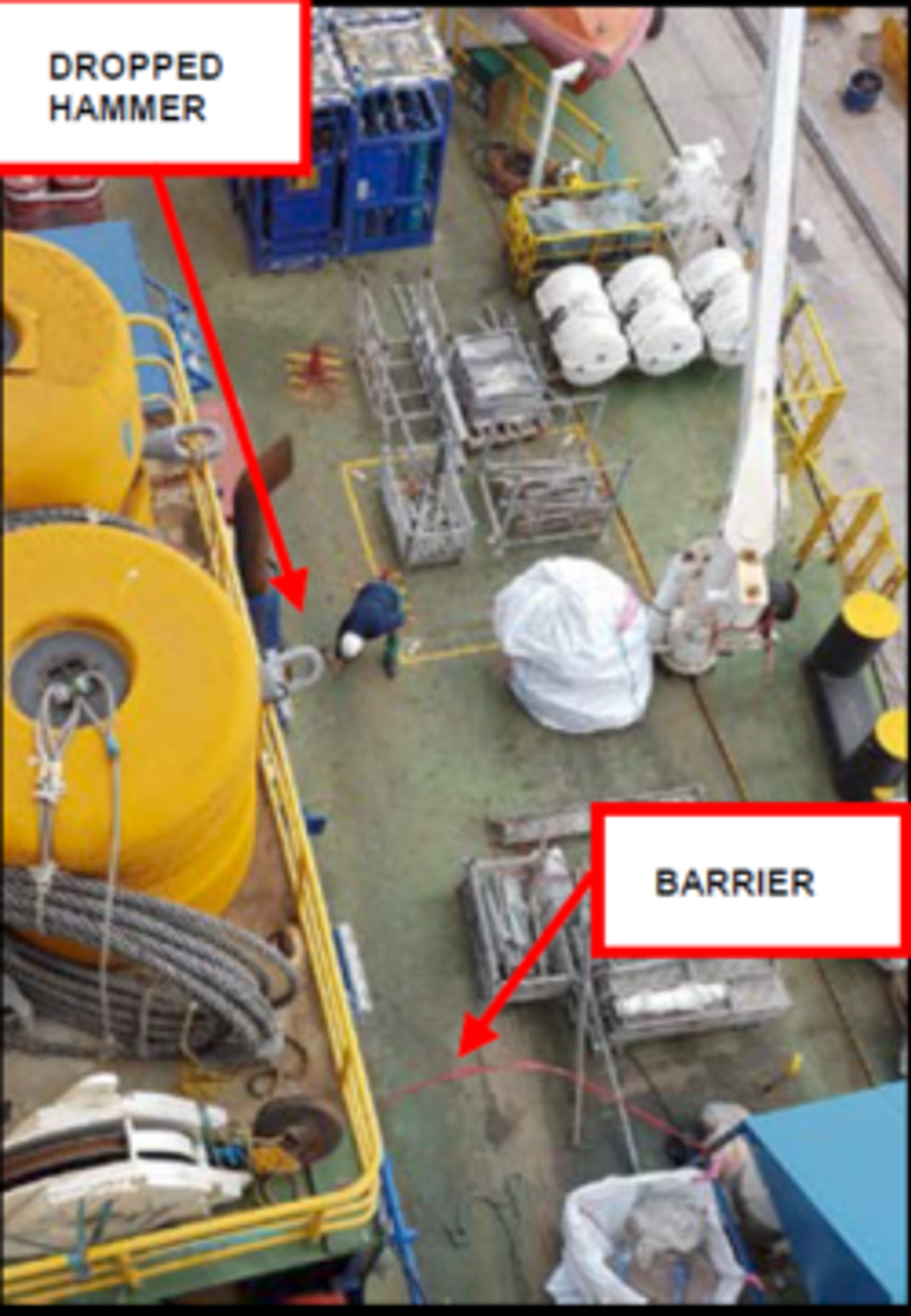

Third party scaffolders were erecting scaffolding along the funnel of a vessel. At the time of the incident, the decks below where the scaffolders were working were barriered off as required by the risk assessment. When moving from one level to the next, a hammer caught on the floor plate and was tipped out of the scaffolder’s belt loop. The hammer slipped free from the attached lanyard (see photo), fell and bounced off the handrail of one of the lower decks and came to rest outside the barriered area on the forecastle deck. No-one was harmed.

Before the scaffolding contractors had started, it had been identified that they did not comply with company dropped object prevention requirements. The vessel officers and project team informed the scaffolding supervisor and shipyard of the requirements for tool tethers to be used on tools. The scaffolding contractor then bought the necessary equipment to comply with company requirements.

What went wrong? What were the causes?

- The lanyard and hammer were not suitable to be used together.

- Due to the inexperience of the scaffolding contractors with working at height tooling, the scaffolder and supervisor did not identify the issue.

- The barriers were insufficient – they were not wide enough and were not in line with the “cone of exposure” guidance provided in the dropped object prevention procedure.

What lessons were learned? What actions were taken?

- Although aware of the requirements for lanyards, the scaffolders were not skilled/trained in their use to the same level as the company personnel. When dealing with subcontractors who have different custom and practice, it is important to take a more active supervisory role to ensure things are done correctly and safely.

- Company requirements were communicated to the yard and scaffolding supervisor verbally at the site. There was no documented transmission of procedures. All documentation should be formally transmitted to all subcontractor’s management to ensure that requirements are rolled out from the top down.

- Members may wish to reiterate:

- the importance of the “cone of exposure” when dealing with dropped object protection, and ensure that this is discussed and given careful consideration

- the importance of ensuring lanyards and tool tethers are applied correctly when working at height.

- the importance of the “cone of exposure” when dealing with dropped object protection, and ensure that this is discussed and given careful consideration

Related safety flashes

-

IMCA SF 02/15

5 February 2015

-

IMCA SF 01/15

16 January 2015

-

IMCA SF 12/11

1 November 2011

-

IMCA SF 01/06

31 January 2006

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.