Dropped object near-miss: Small parts falling from crane rest

- Safety Flash

- Published on 7 December 2015

- Generated on 24 April 2025

- IMCA SF 21/15

- 4 minute read

Jump to:

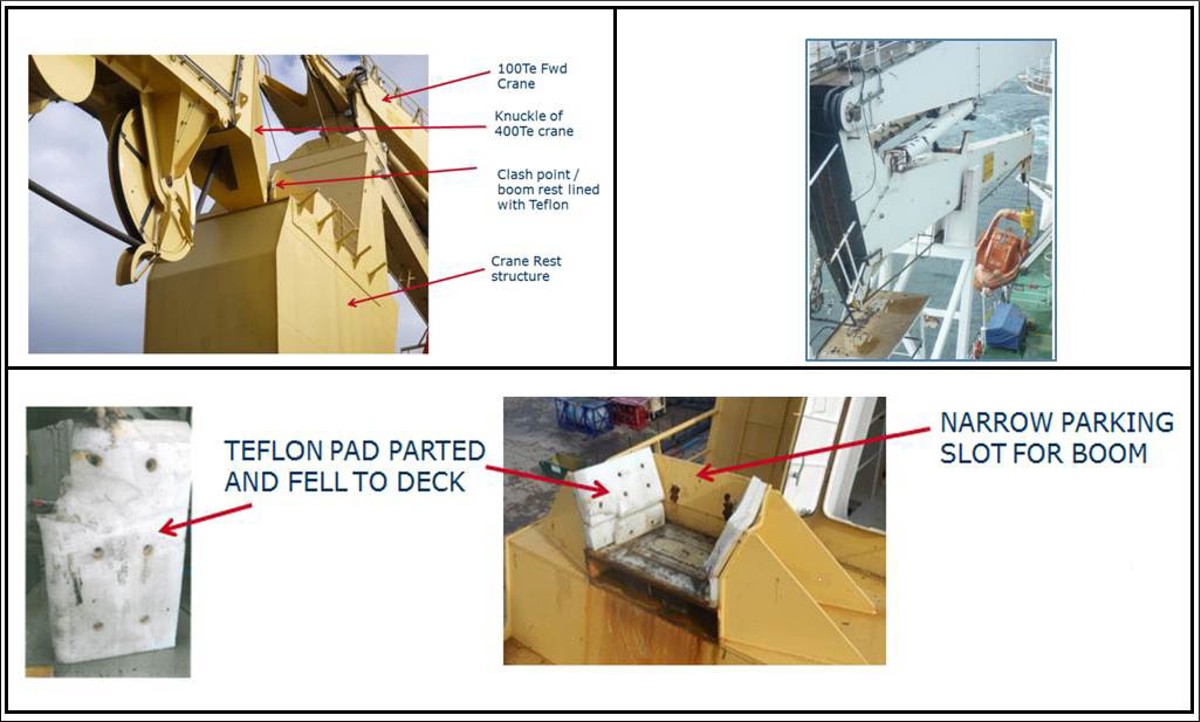

Two Members have reported incidents in which a Teflon pad fell from a crane rest during the parking of the crane.

Incident 1

During piling operations on a chartered vessel, the crane had been used to recover an upending tool to deck. After de-rigging the crane, the riggers left the deck, while the crane operator proceeded to park the crane.

Upon placing the crane boom in the rest, a Teflon pad weighing 6.9 kg, dropped 8.8 metres from the starboard side of the crane rest down to the deck. The pad dropped directly to the deck and landed in an open area, just aft of the crane rest.

Had a person been hit by a dropped object of this weight falling from this height, a fatality could have been the result.

Teflon pad

location of Teflon pads on crane rest

Findings

Our member’s investigation noted that:

- Although at the time the incident was reported to the officer on watch, the company was not informed of the incident until approximately two days later, in which time the crane had been used several times with an identical pad still in situ on the port side of the crane rest.

- Inspection of the dropped pad revealed that sheared parts of only two of six securing bolts remained in the pad.

- A similar incident had occurred on the same vessel some 10 months earlier, where the pad was found to be loose due to sheared retaining bolts.

- This earlier occurrence had not been investigated, allowing a repeat incident to occur with greater consequences.

- The Teflon pads and their retained bolts were inadequately or poorly designed.

- More frequent inspections of crane rest pads should be conducted to identify defects.

Our member concluded that the fundamental design of the pad was flawed. The purpose of the pad is to buffer impact and movement between the crane and the crane rest to provide protection to the crane boom during parking, stowage and start up. The weakness in the design was demonstrated by the fact that this was the second similar incident to have occurred. Additionally, had the earlier incident been investigated and remedial action taken, this second incident need not have occurred.

Actions

Our member took the following actions:

- Inspection of the condition of crane rest pads and associated retaining bolts.

- Addition of crane rest pads to planned inspection/maintenance routines.

- Considered the use of secondary retention devices on crane rest pads.

- Reinforced the importance of reporting incidents in a timely manner.

- Ensured deck crews took a ‘Time Out for Safety’ (TOFS) to reinforce safe crane technique, including the requirement to bank the crane at all times – including parking and releasing the hook/headache ball from its stowage box.

Incident 2

A member reported frequently dropped objects from crane rests during parking and when the crane boom was raised out of the crane rest. The falling objects had been Teflon or wooden landing pads, rubber protection, steel cover plates and nuts/bolts. An example is highlighted below:

What were the causes?

Our member identified the following causes:

- The crane rest had a tight fit/narrow parking slot for the crane boom.

- The crane rest protection cracked and although bolted dislodged as a result of everyday contact from the crane boom.

- Additionally it was difficult to monitor the landing/raising of the crane boom from the crane cabin.

Actions

Our member took the following actions:

- Teflon pads have been re-secured using larger washers on the bolts to prevent the bolts from being pulled through the Teflon/rubber, and a secondary chain has been attached to prevent the Teflon/rubber from falling to deck.

- Area around boom rest barriered off before parking/raising the crane boom.

- A dedicated spotter has been used to monitor the crane parking/raising operation.

- Cameras installed to aid inspection of the crane boom rest and assist parking/raising.

Recommendations

- Ensure that all appropriate personnel are aware of the potential for clashes between the crane booms and the boom rest protection.

- Check the condition of Teflon/rubber protection in the crane rests.

- Where necessary, use a spotter to assist with parking/removal of the crane boom in/from the rest.

- Always control the area around the crane boom when parking/lifting the crane boom from the crane rest.

- Highlight awareness of how vessel motion can have a negative impact on crane movements.

Members may wish to refer to the following similar incidents (search words: crane, parts, dropped):

- Near-miss: Dropped object fell from crane boom

- Near-miss dropped object: Protector plate drops from crane

These incidents serve to highlight the need to pay further careful attention to crane maintenance and to the clear risk of parts falling from the crane itself, in addition to managing the risk of objects falling from the load.

Related safety flashes

-

IMCA SF 11/15

10 August 2015

-

IMCA SF 10/15

16 July 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.