Near miss: Diver’s umbilical trapped

- Safety Flash

- Published on 23 August 2019

- Generated on 7 March 2026

- IMCA SF 20/19

- 3 minute read

Jump to:

During near-shore diving operations, a diver's umbilical became trapped against a seawater intake.

What happened?

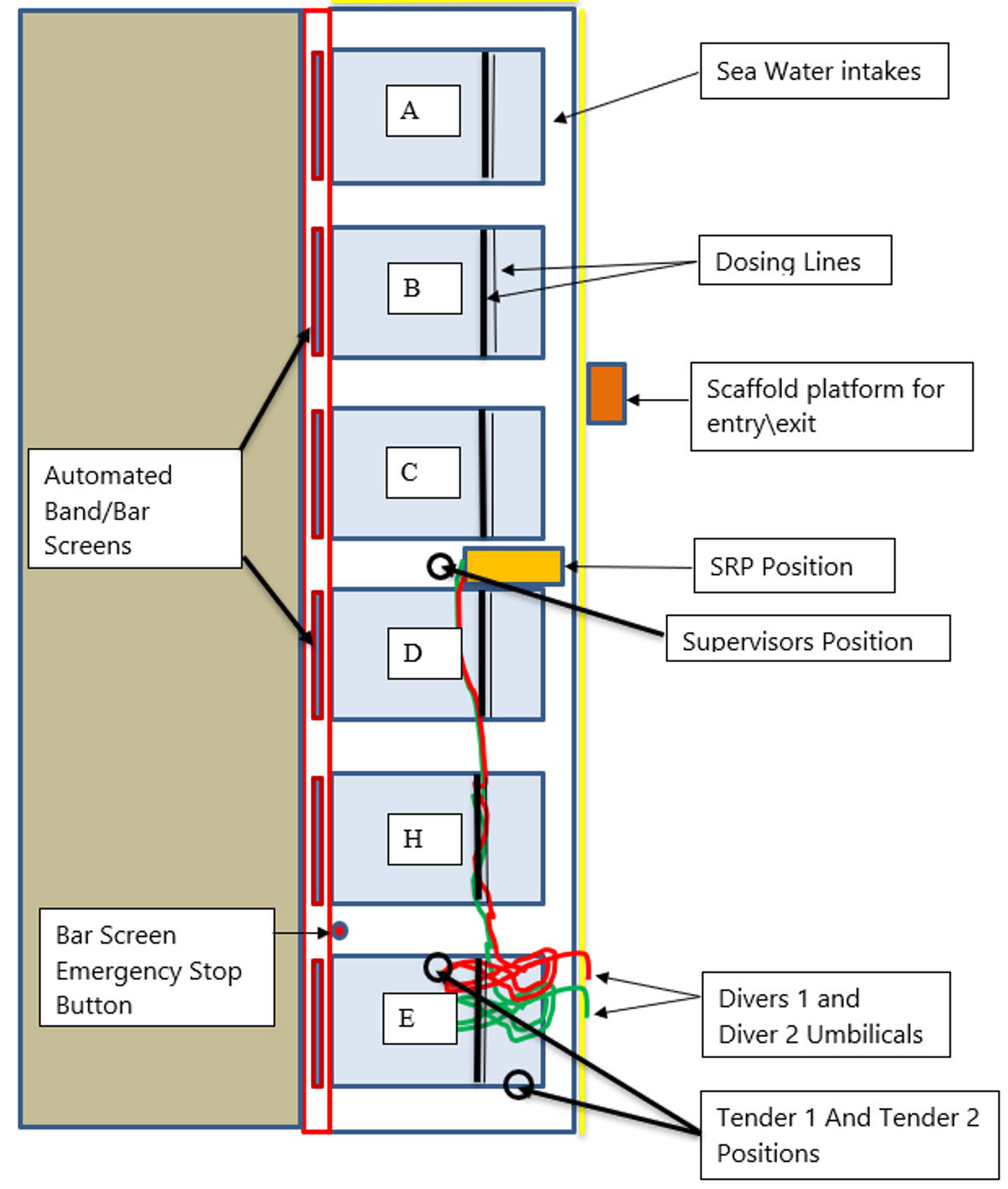

The dive team (2 x divers, 2 x tenders and dive supervisor) had completed a task and were busy recovering all the tools and rigging to recover to surface. Both tenders were receiving the tools from the water, and both diver’s umbilicals were briefly secured to a railing.

Diver 1 was looking for any tools left behind on the seabed when his excess (untendered) umbilical drifted into one of the seawater intake channels and lay against the screen. The automated bar started and Diver 1’s umbilical became trapped.

The rotating bar emergency stop button which was less than 10 m away from dive control was immediately used by the dive supervisor.

Diver 1 transferred onto his bailout and upon confirmation that the band screen was stopped, Diver 2 approached to assess the situation. The bar screen was manually turned in reverse, in order to free Diver 1’s umbilical.

Onsite client personnel manually reversed the band screen direction before both divers returned to surface, and diving operations were suspended.

There were no injuries sustained to either diver and upon inspection of the umbilical, there was a small perforation in the main airline approximately 11 m from the helmet.

The communications cable also sustained cut damage.

What went wrong? What were the causes?

Contributing factors:

- Diver umbilicals were tied off on the railing and were not being actively tendered; tenders were onsite but were engaged in other activities at the time (tender 1 was removing lifting gear and equipment from the crane hook, tender 2 was recovering tools using the messenger line).

- Seawater intakes were not isolated.

Immediate causes:

- There was no isolation of bar screens on the seawater intakes before diving began.

- Umbilicals were not being actively tendered.

- Diver 1 failed to monitor his umbilical slack whilst he was engaged in recovering tools.

Root causes:

- Inadequately engineered controls: failure to implement suitable equipment isolation.

- Inadequate oversight or supervision.

What actions were taken? What lessons were learned?

- Thorough review and revision of risk assessment for this work.

- Revision of dive log requirements to include appropriate work planning and appropriate permit to work (PTW) requirements.

- Debrief and formal review by dive team, of method statement, dive plan and risk assessment, with particular reference to:

- umbilical management

- isolation of sea water intakes/band screens

- are there enough people involved?

- ‘last minute’ risk assessment

- guarding against complacency and the hazards of ‘routine’ activities.

Related Safety Flashes

-

IMCA SF 03/17

13 February 2017

-

-

IMCA SF 15/09

23 October 2009

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.