Fatal diver incident due to uncontrolled differential pressure

- Safety Flash

- Published on 2 August 2016

- Generated on 6 March 2026

- IMCA SF 20/16

- 2 minute read

Jump to:

The International Association of Oil and Gas Producers (IOGP) has published the following safety alert regarding a diving fatality which was caused by uncontrolled differential pressure.

What happened?

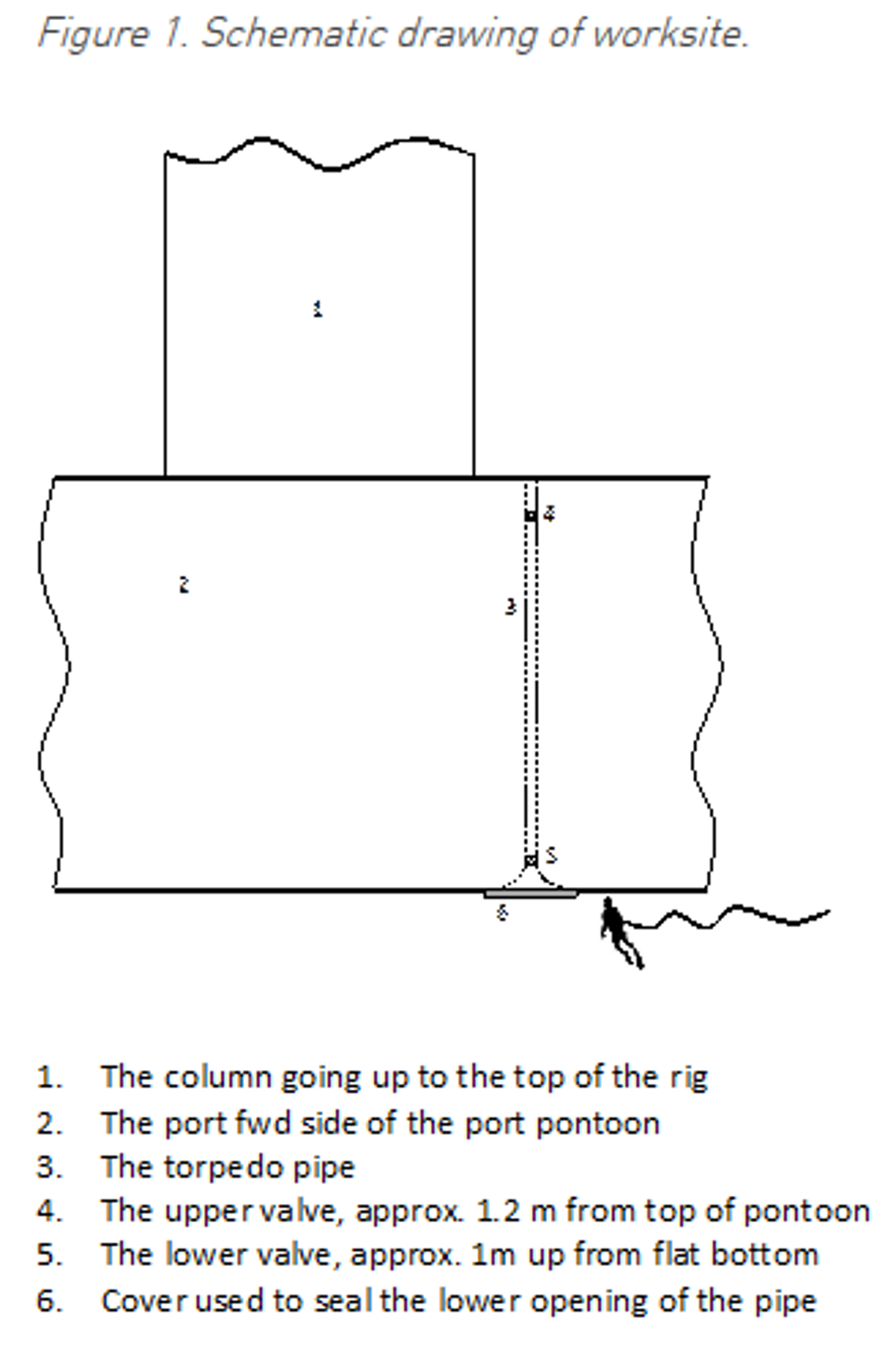

The incident occurred when the diver was preparing to blind off the torpedo pipe on the rig’s pontoon. The torpedo pipe is a 0.45m diameter pipe running through the pontoon of the rig to allow for wires used when thrusters are to be replaced. The length of this pipe was 13m, with one lower valve 1m up from the bottom, and one upper valve 1.2 m from the top of the pipe. The valves were partly open to equalise the pipe.

A safety meeting had been conducted before work started, and this pipe was the seventh to be worked on. The diving was carried out following the NORSOK U-103 standard for inshore diving.

What went wrong?

When the diver introduced air into the pipe an artificial, undiscovered concrete plug on top of the upper valve broke and the divers head and left arm were sucked into the pipe causing great pain. The standby diver, being fully dressed, entered the water immediately (within 30 seconds) and the wounded diver was brought to the surface within 9 minutes. At the time he had stopped breathing, but his breathing and pulse were regained through CPR. The diver was sent to hospital where he died two days later.

This fatal diving incident was due to uncontrolled differential pressure.

IOGP Safety Alert number 275 can be seen at safetyzone.iogp.org/SafetyAlerts/alerts/Detail.asp?alert_id=275

The following information will also be of use and interest:

- UK Health & Safety Executive (UKHSE) Diving Information: Sheet No 13 Differential pressure hazards in diving

- UK HSE research report: RR761 Differential pressure hazards in diving.

Related Safety Flashes

-

IMCA SF 06/14

16 April 2014

-

IMCA SF 14/11

23 December 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.