Parting of hawser and bulk cargo hose during tandem mooring

- Safety Flash

- Published on 25 July 2017

- Generated on 7 March 2026

- IMCA SF 18/17

- 2 minute read

Jump to:

During at-sea bunkering operations between two vessels, a mooring line parted and then a fuel hose parted also.

What happened?

There was no spillage of fuel. The incident occurred when one vessel (Vessel A) arrived to deliver fuel to another vessel (Vessel B), which was at anchor with thrusters running.

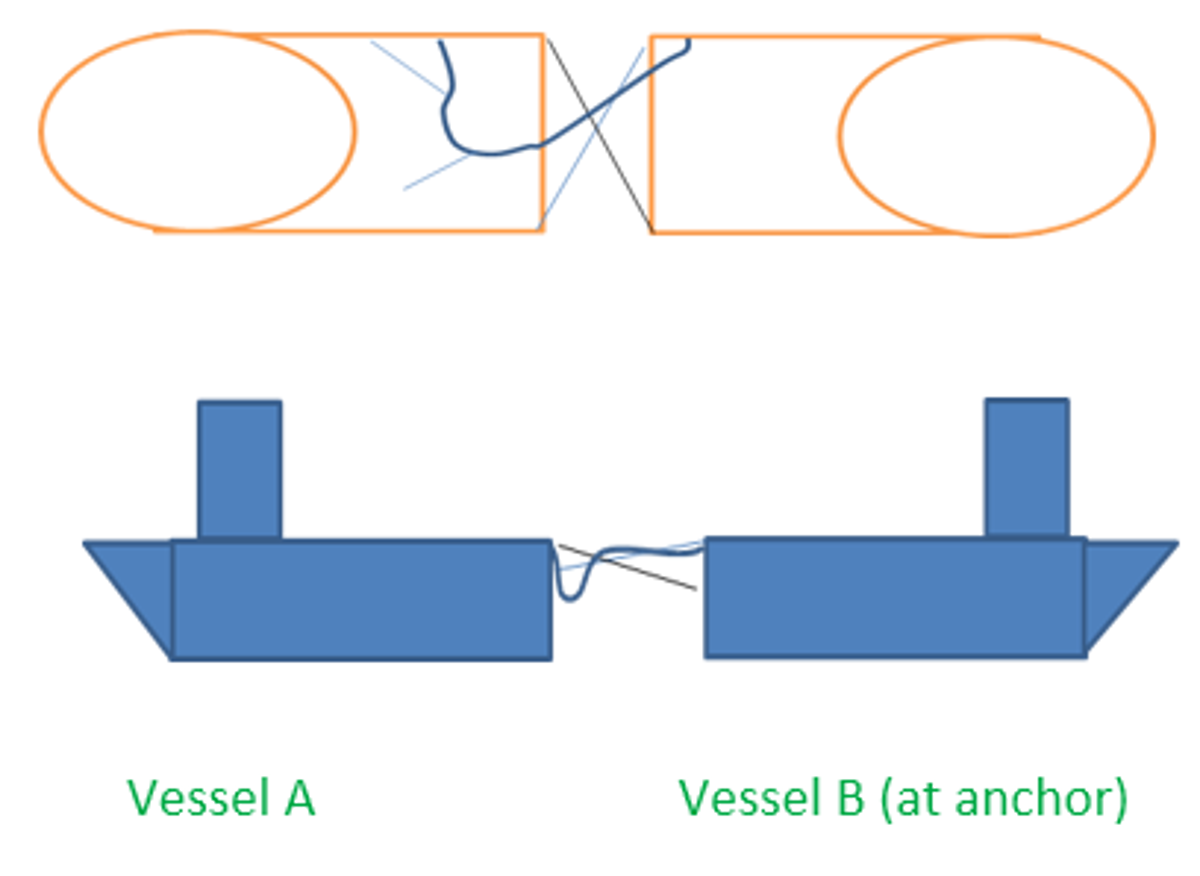

It was decided to moor both vessels in tandem. Vessel B would maintain heading and control yaw using thrusters. Both vessels were moored to each other using one rope in a criss-cross fashion.

Vessel B could not start its fuel pump and thus the fuel transfer could not be started. The two vessels stayed connected in tandem.

The mooring rope from Vessel A parted due to jerking and continuous yawing. Crew on Vessel B were told to close the deck fuel valve and disconnect the hose for retrieval. The hose was disconnected and crew on Vessel A started retrieval using the port tugger winch. While they were retrieving the hose, it got entangled with the remaining single mooring rope and the vessel structure, and the hose parted on deck. No spillage was noticed as hose was empty.

The parted mooring rope and bulk cargo hose were retrieved by Vessel A.

What went wrong? What were the causes?

- There were 1.5m seas and wind of approx. 14 knots. Both vessels were yawing – the mooring ropes was getting intermittent jerks which resulted in one of them parting. The uncontrolled heaving of the bulk cargo hose resulted in it parting.

- Both vessels could have decided to call off or postpone the operation until the fuel pump was operational and/or weather would improve.

Related safety flashes

-

IMCA SF 30/16

9 November 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.