Injuries sustained whilst trying to stop moving objects

- Safety Flash

- Published on 25 November 2014

- Generated on 2 March 2026

- IMCA SF 18/14

- 3 minute read

Jump to:

A Member has reported two similar incidents, which happened within two days at two very different locations, in which persons were injured whilst trying to stop moving objects.

What happened?

The first during pipe handling at an onshore yard, the second during maintenance work on a vessel under way. The first incident was classified as a medical treatment case, the second as a first aid case.

Incident 1 – trying to stop a rolling pipe

During ‘routine’ pipe handling at an onshore yard a pipe rolled from the forks of a wheel loader. Although this should not have happened the situation was not of itself dangerous. All personnel were at a safe distance as per procedure. The speed of the rolling pipe was low and there was a lot of empty space around. The pipe first rolled 1.5m from the loader and a further 1.8m to come to a stop. However, the banksman guiding the operation followed after the rolling pipe trying to stop it. When putting his foot against one pipe end he slipped and the pipe end rolled over his foot.

Swipe to see next image

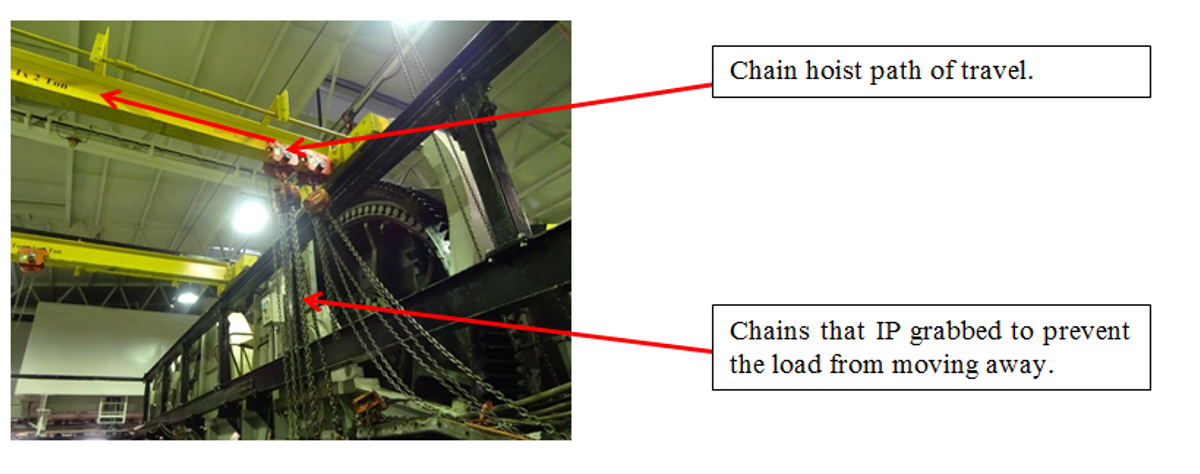

Incident 2 – Trying to stop a moving chain block

This incident happened during ‘routine’ maintenance work on a gearbox. It is usual to conduct such activities while at sea under good weather conditions. For that day however the bridge had announced that bad weather was upcoming. Although the crew members were aware of the vessel motion they did not consider them severe enough to impact the safety of the worksite. However, the vessel started rolling with a double amplitude of 7° which caused a chain block suspending a lifting frame to start uncontrolled travelling along its lifting beam. A mechanic tried to catch the chain of the chain block, in order to regain control of the lifting frame before it could hit equipment or personnel in the vicinity. While doing this, his little finger got stuck in one of the chain links which caused an injury to the top of his little finger.

Chain block location

Our Member notes:

This safety flash is not about the root causes of loss of control over the objects, which in both cases were very different. It is about the immediate cause, stepping in without thinking to try and stop something. It serves to highlight the reactions of people stepping in and trying to rectify the situation, to bring the object under control again, stopping it. This appears to be a natural behaviour. A couple of years ago a lifting supervisor noticed that a lifting shackle was incorrectly positioned and stepped in to rectify the situation. The shackle toppled over and injured his hand.

Often such reactions are in a hurry or even in a state of panic. People are not aware of potential risks in that particular situation because they do not take (or have) the time to think. There can be a lack of oversight and understanding of the situation.

Job Safety Assessments should consider potential loss of control and define what mitigations should be in place.

Related safety flashes

-

IMCA SF 02/14

20 February 2014

-

IMCA SF 15/13

23 September 2013

-

IMCA SF 08/06

22 June 2006

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.