Fatality during lifting operations

- Safety Flash

- Published on 20 December 2013

- Generated on 10 February 2026

- IMCA SF 18/13

- 3 minute read

Jump to:

A Member has reported an incident in which a crew member suffered fatal crush injuries during lifting operations on an offshore vessel.

What happened?

The incident occurred whilst rigging equipment was being transferred from one part of the vessel to the spar deck. This operation was conducted by the crane operator and rigger team. One of the loads to be transferred involved a Dyneema sling arrangement that was connected to an ROV reverse hook. The sling weighed approximately 0.7 tonne and the hook 2.3 tonne, giving a combined weight of 3.0 tonne. The rigging assembly was prepared on the main deck by the lead rigger and a rigger.

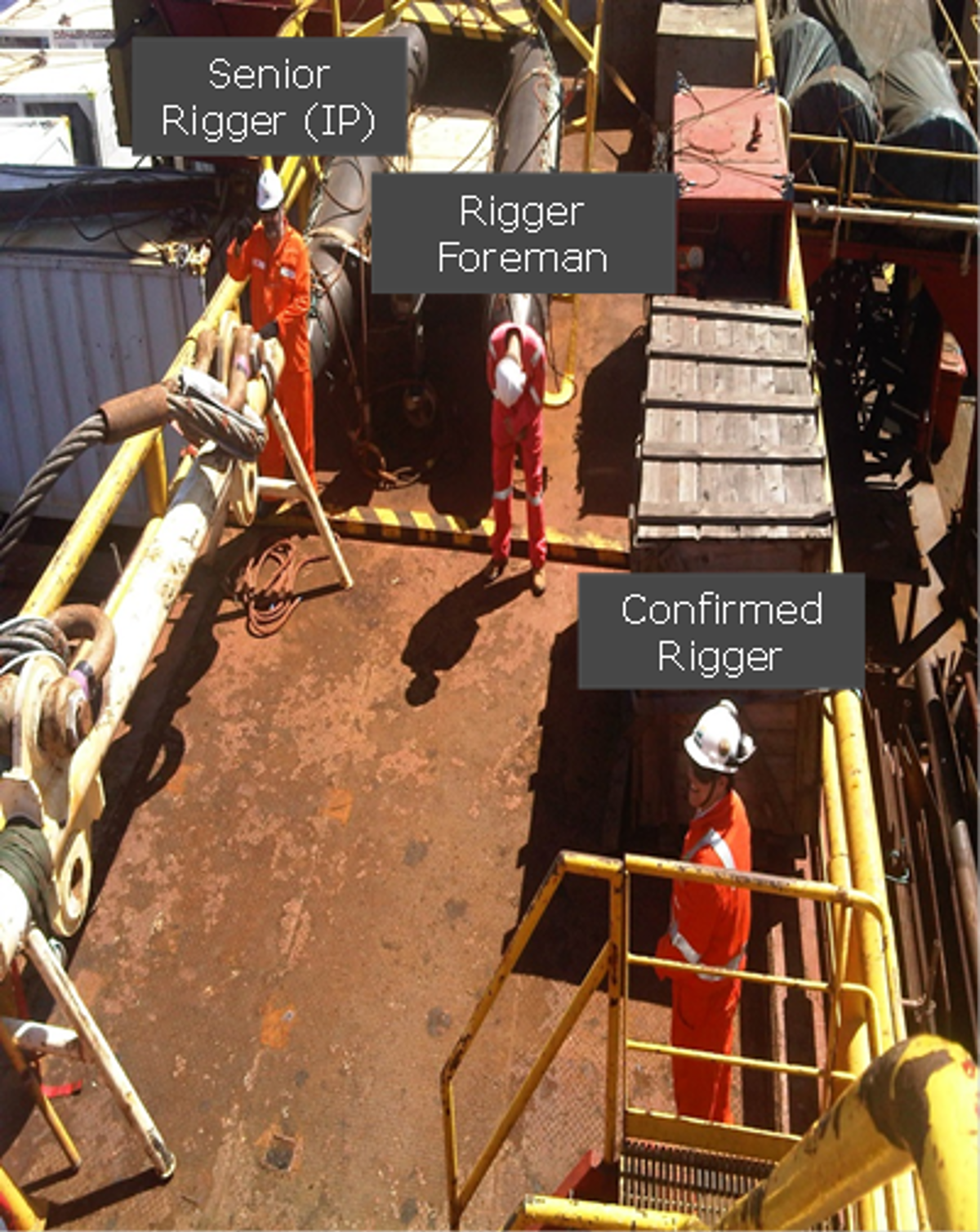

The rigger foreman, senior rigger (IP) and the certified rigger were located on the spar deck. They had already received and sea-fastened the spreader beam and were awaiting the next load to arrive. As the Heavy Lift Crane boom was located in its rest, the Manitowoc crane boom could not be positioned to allow a plumb lowering of the load onto the spar deck. The senior rigger (IP) was asked to move to a safe position by the rigger foreman.

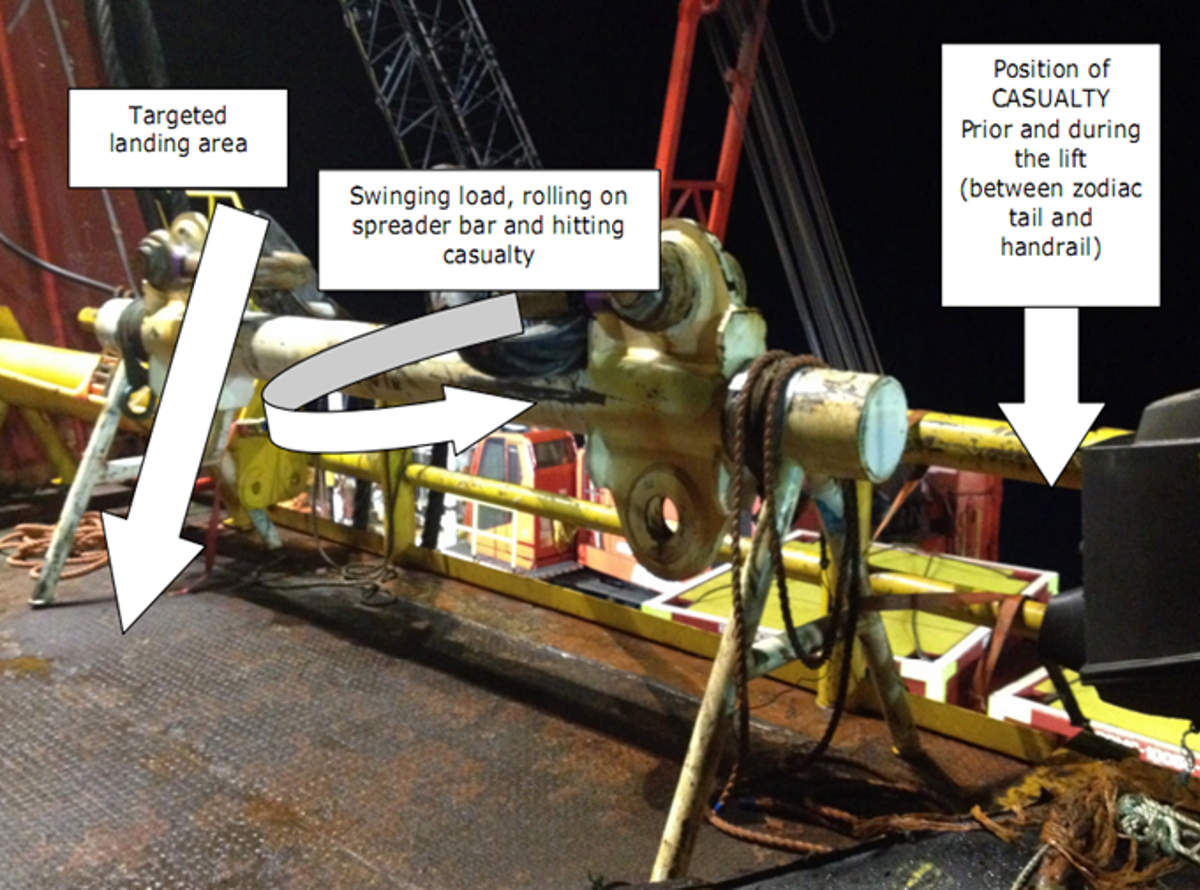

After confirmation was given to send the load it arrived suddenly at the spar deck; it landed inboard against the spreader. It then slid forward towards the senior rigger, who was struck twice by the suspended load. Due to his height the load made contact with his chest and crushed him against the cargo rail, at his back.

The alarm was raised and a response activated. The vessel doctor found no vital signs, he applied an airway, gave oxygen, fitted a cannula and administered adrenaline to the senior rigger but there was no response. Resuscitation continued but was unsuccessful and the senior rigger was declared dead.

position of riggers on the spar deck

Dyneema sling and ROV reverse hook

illustration of load movement towards injured person

What were the causes?

Our member’s early investigation notes that;

- Incident occurred in daylight hours.

- Wind was 20-22 knots ESE.

- Significant wave height 2.7 m, with maximum wave height of 3.1 m.

- The senior rigger may have felt he was already in a safe position, between the end of the spreader bar and the stern of the zodiac, not anticipated he was actually at risk.

- The slide forwards of the heavy load may have been caused by:

- induced momentum from crane swing

- contact with the parking leg of the spreader beam

- contact with the lifting eye, nubbins of spreader beam

- induced spin from offset of centre of gravity

- vessel motion from sea state, or

- any combination of the above factors.

Lessons learned

Our Member reiterates the following vital points with regards to all lifting operations:

- Careful consideration should be given to all lifting operations. All lifts require planning whether they are ‘routine’ or non-‘routine’.

- Careful consideration should be given to the positioning of personnel – particularly riggers and banksmen, during lifting operations;

Members may also wish to refer to Guidelines for lifting operations.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.