High potential near miss: unplanned handling of unexploded ordnance

- Safety Flash

- Published on 3 August 2018

- Generated on 29 December 2025

- IMCA SF 17/18

- 3 minute read

Jump to:

During debris removal/recovery operations being undertaken along a subsea cable trenching corridor, several items of unexploded ordnance (UXO) were bought to the surface and landed on deck with recovered debris.

What happened?

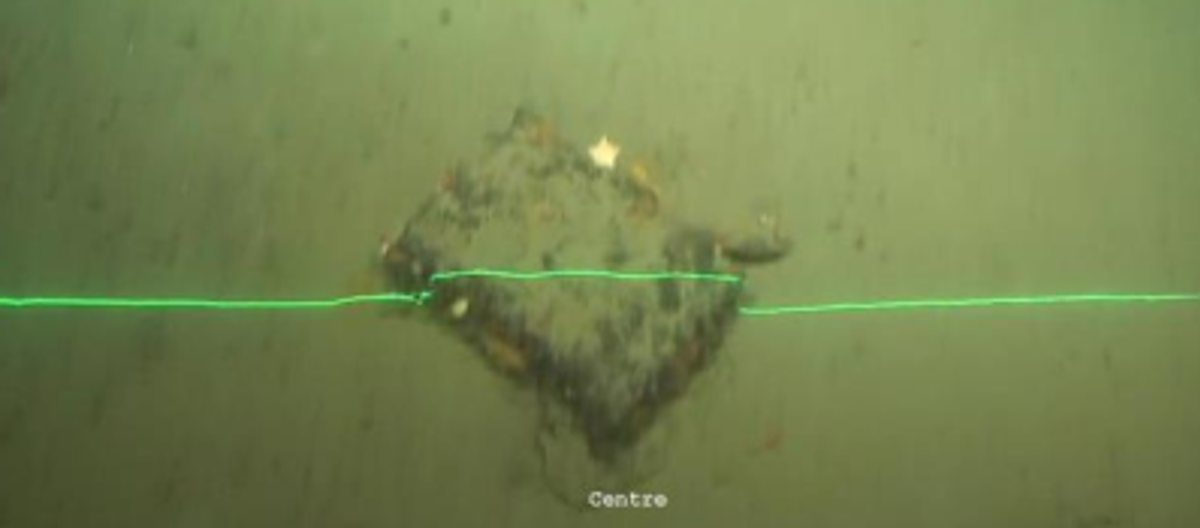

During the initial phases of the operation, several boxes previously classified as concrete debris were investigated and observed to be boxes containing dumped munitions. These boxes were left in place on the seabed. Later in the operation an item recovered, believed to be ‘machine parts’, was recovered to the vessel deck. The box was handled by vessel crew before they realised it was a WWII munitions box. Expert advice was obtained and the UXO was returned to the seabed.

What went wrong?

Investigation determined that the likelihood of an uncontrolled detonation was low. However, since the potential risk at the time of handling was unknown, the situation was defined to be out of control and thus classified as high potential.

Our member noted a number of barrier failures leading up to the recovery of the debris:

- Contact had been made with the local Armed Forces regarding the trenching corridor. It was stated that a re-organising of this service within the Armed Forces has caused information to be lost or misplaced. The information received back from the relevant department dealing with this information was that this corridor was ‘clean’ and free from known WWII dumped munitions.

- A pre-survey was carried out of the area and most of the debris was located. However, none of the items were identified as potential UXOs. Machinery parts, concrete blocks, wire, barrel etc. were used to describe the findings.

- A risk assessment was completed for debris removal. However, UXO was not mentioned as it was perceived not to be a risk due to pre-survey information.

- An ROV attempted to move ‘concrete objects’ which disintegrated, and cartridges fell out. A cartridge magazine was picked up by the ROV and a request made for it to be brought to deck. Some cartridges were released, a magazine was released by the ROV and dropped to seabed. No ‘all stop’ called at this stage.

- Shift logs identified that the ROV continued to locate and move additional items of potential ammunition into subsea basket and relocated what was thought to be barrels/drums, but what were later identified to be munitions. Operations continued and no ‘all stop’ called.

- Personnel handled dangerous items, bringing them to deck, and one person tampered with a piece of ammunition attempting to verify its condition. Personnel raised concern to on-board management.

- Eventually the authorities were contacted, and the advice provided was to return the recovered items to the seabed.

What were the causes?

- Immediate causes:

- lack of valid information

- lack of correct identification of debris

- lack of management intervention

- lack of adherence to procedures/lack of direction

- complacency

- Underlying causes:

- failure to apply suitable management of change (MoC) and adequately assess risk

- fundamental misunderstanding of key risks.

What were the main lessons learned?

- Reinforcement required of stop work authority and MoC, specifically actions towards managers/leaders.

- Revision required for procedures covering actions to be taken in the event of discovering dangerous items such as UXO.

- Method of survey to be re-evaluated.

- Additional training and guidance to teams involved in debris clearance operations.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.