Fall from height – LTI

- Safety Flash

- Published on 13 July 2017

- Generated on 18 December 2025

- IMCA SF 17/17

- 3 minute read

Jump to:

A supervisor fell through an upper deck hatch on a vessel alongside, suffering injuries that required surgery and physiotherapy and several months away from work.

What happened?

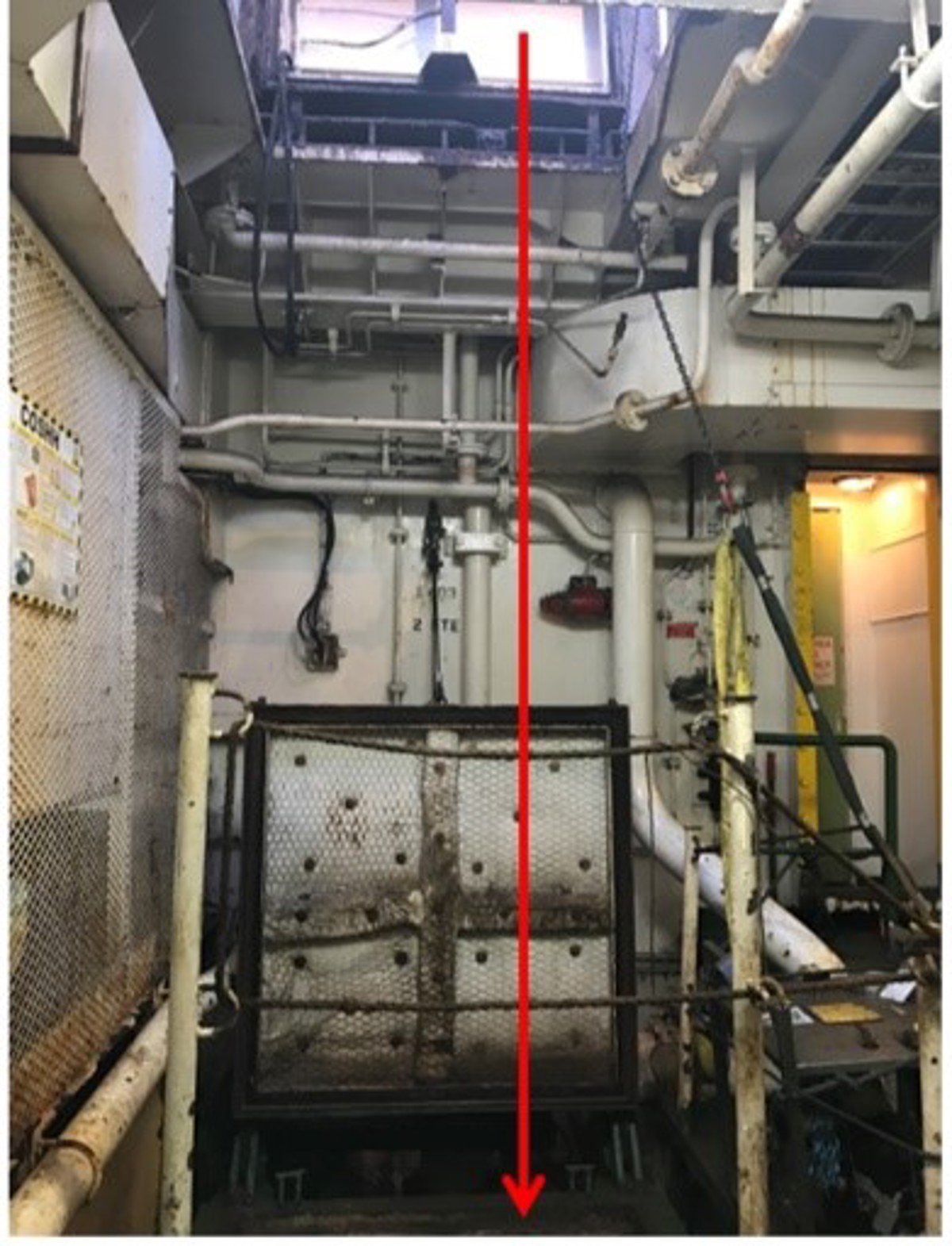

On a vessel that was alongside, crew were engaged in offloading equipment from below-decks through a series of hatches, when their supervisor lost his footing and fell through the hatches, falling 7m.

The supervisor was taken to hospital with a dislocated and fractured shoulder and a broken ankle. The ankle injury required surgery, and physiotherapy over a number of months before he was fit to return to work.

What went wrong?

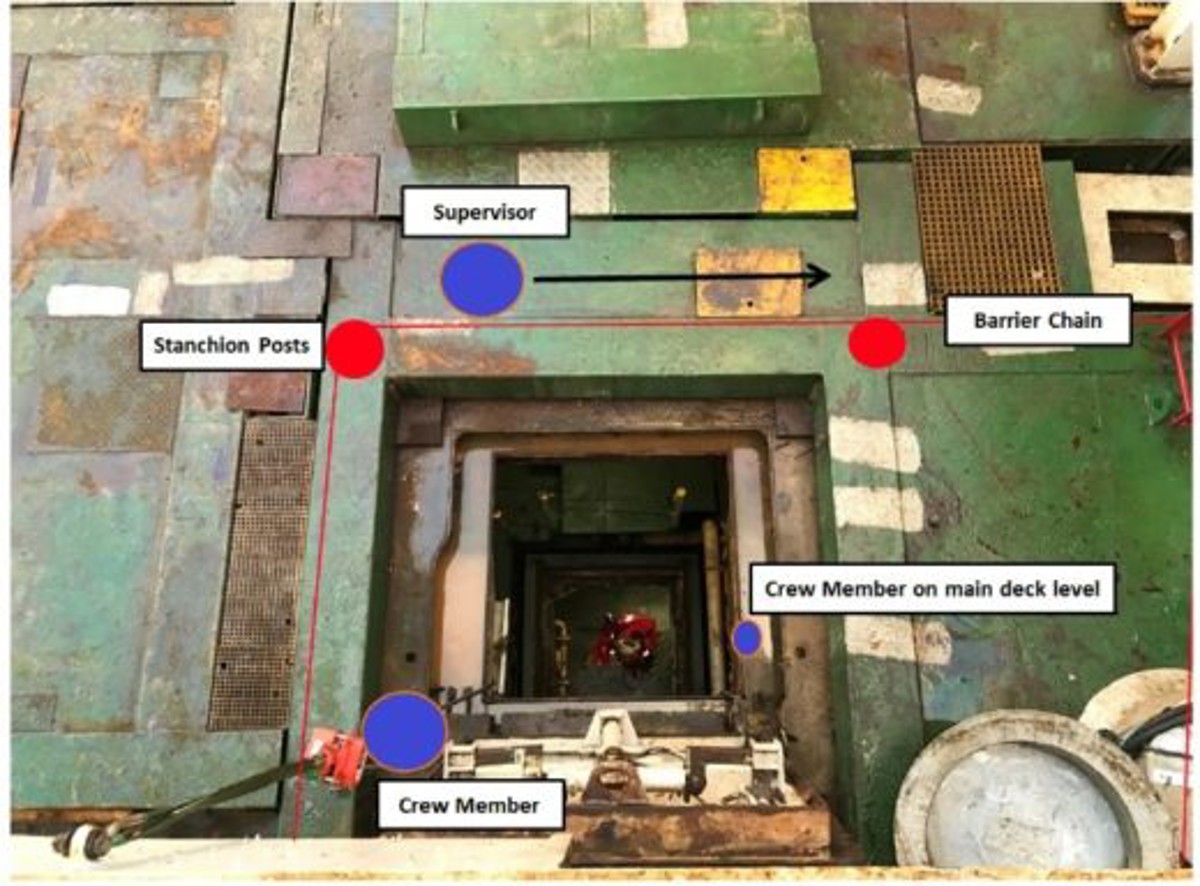

A portable barrier (two stanchions and length of chain) was put around the area to warn of a trip hazard. This was because although it was closed, the hatch was not fully sea-fastened.

Recovery to deck of the equipment could be conducted without use of the vessel crane, and the crew held a Toolbox Talk and Pre-Task Assessment before starting, to discuss the method of lifting between the two decks using two chain pulls joined together.

Crew operating the chain pulls were stood inside the barriered off area, wearing fall arrest harness and inertia reel. Their supervisor was on the upper main deck outside of the barriered off area. As the equipment was being lifted using this technique, he moved to get a better look at what was happening. As he did so, he lost his footing and tipped forward toward the portable barrier stanchions and chain, and fell through the barrier and down the hatch.

What were the causes of the incident? Causal factors identified

- Fall prevention barriers that were around the upper main deck hatch were not suitable or sufficient. There was insufficient robust barrier hardware available on board.

- Several trip hazards existed around the area:

- where the task was being carried out

- where the supervisor was standing

- where the portable barrier was previously positioned – this was also close to the edge of the open upper main deck hatch.

- where the task was being carried out

- The supervisor was too close to open hatch hazards without sufficient fall protection.

- Visual obstruction prompted the supervisor to move to get a better look at the activities he was supervising. In so doing he knocked against the portable barrier.

- The supervisor lost his footing/balance close to the edge of the portable barrier and open deck hatches.

- A generic or blanket Permit to Work was used for the recovery/lifting of this equipment using a working at height/chain pull method, rather than a specific Permit to Work.

What lessons were learnt?

- Time spent discussing the lift in detail, may have detracted from proper review of the suitability of the existing barrier, and possibly divided attention over risks from the lift versus that from the fall.

- Better management required of Permit to Work system for specific and non-routine tasks.

- A proper review of the barrier previously put in place, and its adequacy to protect against falls versus highlighting a potential trip hazard, seems to have been forgotten during the planning stages of the task.

- Lapses do happen – Comprehensive checklists to confirm specific actions required can help address potential lapses. These checklists could be included in pre-task dynamic/situational assessment, and standard pre-start checks made within the Permit to Work process.

Related safety flashes

-

IMCA SF 23/16

13 September 2016

-

IMCA SF 08/08

24 April 2008

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.