Mooring rope fouled the propeller and parted

- Safety Flash

- Published on 30 June 2016

- Generated on 7 February 2026

- IMCA SF 17/16

- 3 minute read

Jump to:

A member has reported an incident in which mooring ropes were slacked more than required resulting in a fouled propeller.

What happened?

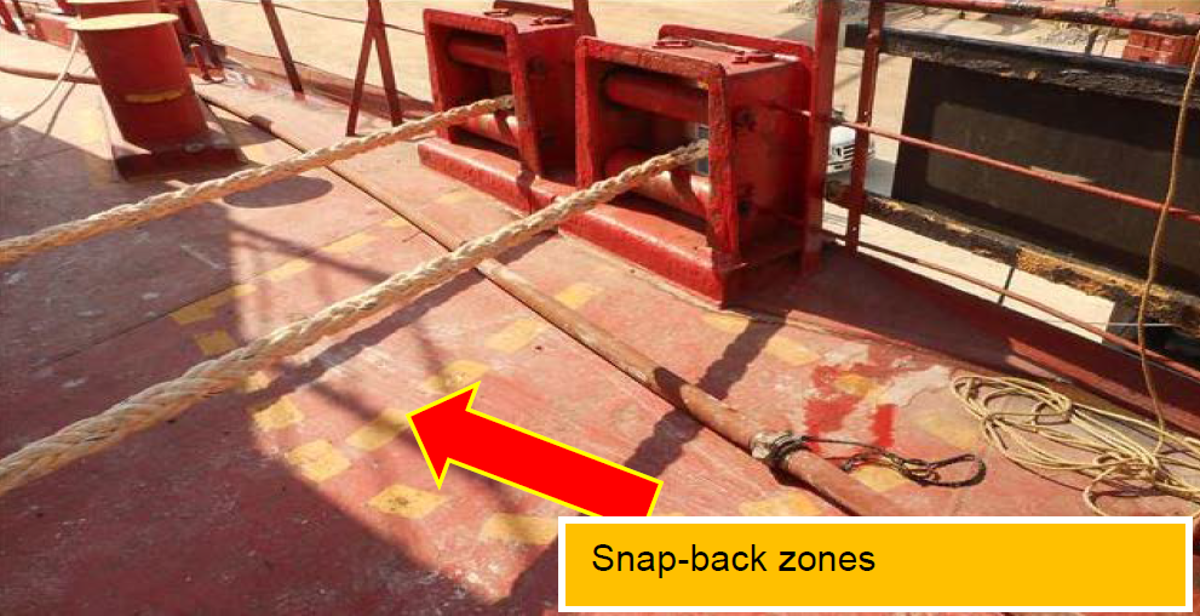

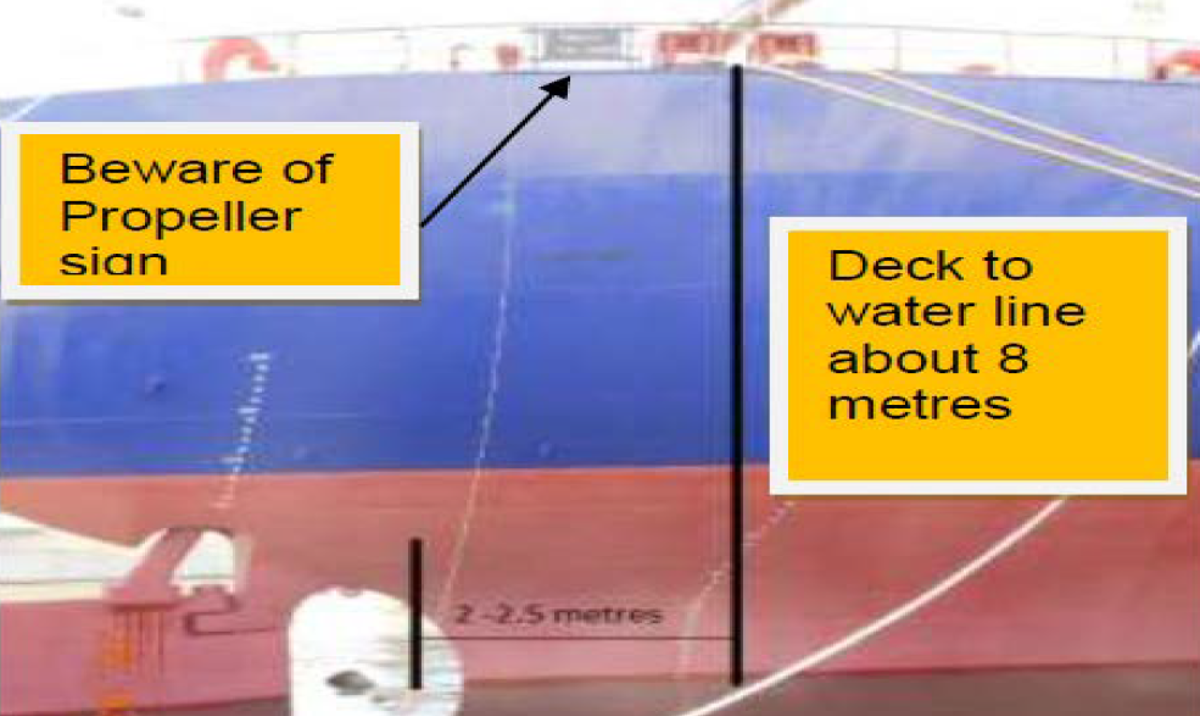

The incident occurred during berthing operations when the engines were being used. The fouled lines became taut and parted. Fortunately, the recoil was vertically up and down, as the angle was 90 degrees, straight down from the universal leads to the propeller. The men on stations were standing in the snapback zone, but the near vertical whiplash missed them.

The propeller was fouled – there were damaged rope guards and mooring ropes. The vessel had to come off-hire for repairs (fortunately the stern tube seal was not damaged).

Our member’s findings included the following.

- Crew were using appropriate personal protective equipment (PPE) for the task.

- The immediate cause of the incident was excessive slackening of the ropes when the propeller was turning.

- Causal factors included:

-

- lack of situational awareness and inadequate understanding of the physical constraints of the ship as the leads being almost directly above the propeller

- ineffective communication between bridge and mooring station

- bridge issuing orders to slack when the propeller was turning

- mooring stations obeying the instructions without checking propeller clearance and/or warning the bridge

- excessive line laid out on deck which ran out to foul the propeller

- there was no risk assessment carried out for this mooring operation

- there was no safety briefing and no tool box talk carried out

- there was inadequate supervision.

-

- The root causes were found to be:

-

- inadequate understanding of risks involved

- lack of situational awareness of the surroundings.

-

Our member took the following preventative actions:

- Ensure proper risk assessment carried out for mooring operations.

- Ensure safety briefing and toolbox talk conducted by the person in charge, ensuring that all crew involved in the mooring operation know the risks and actions to prevent incidents.

- Vessel joiners should be properly briefed on ship-specific tasks and constraints.

- Ensure more effective communication between bridge and mooring stations to include warnings as to prevent such incidents.

- Person in charge to take extra precautions and ensure they supervise the area and task properly.

- Re-train crew on hazards and dangers involved in mooring operations.

- Entire mooring deck area should be considered a potential snap-back zone.

- All crew working on a mooring deck should be made aware of this with clear visible signage.

Members may wish to refer to the following:

Related Safety Flashes

-

IMCA SF 04/09

2 April 2009

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.