LTI – Crew person cracked shin bone

- Safety Flash

- Published on 1 July 2023

- Generated on 19 December 2025

- IMCA SF 16/23

- 2 minute read

Jump to:

An engineer suffered a broken shin when he slipped taking a shortcut into the engine room

What happened?

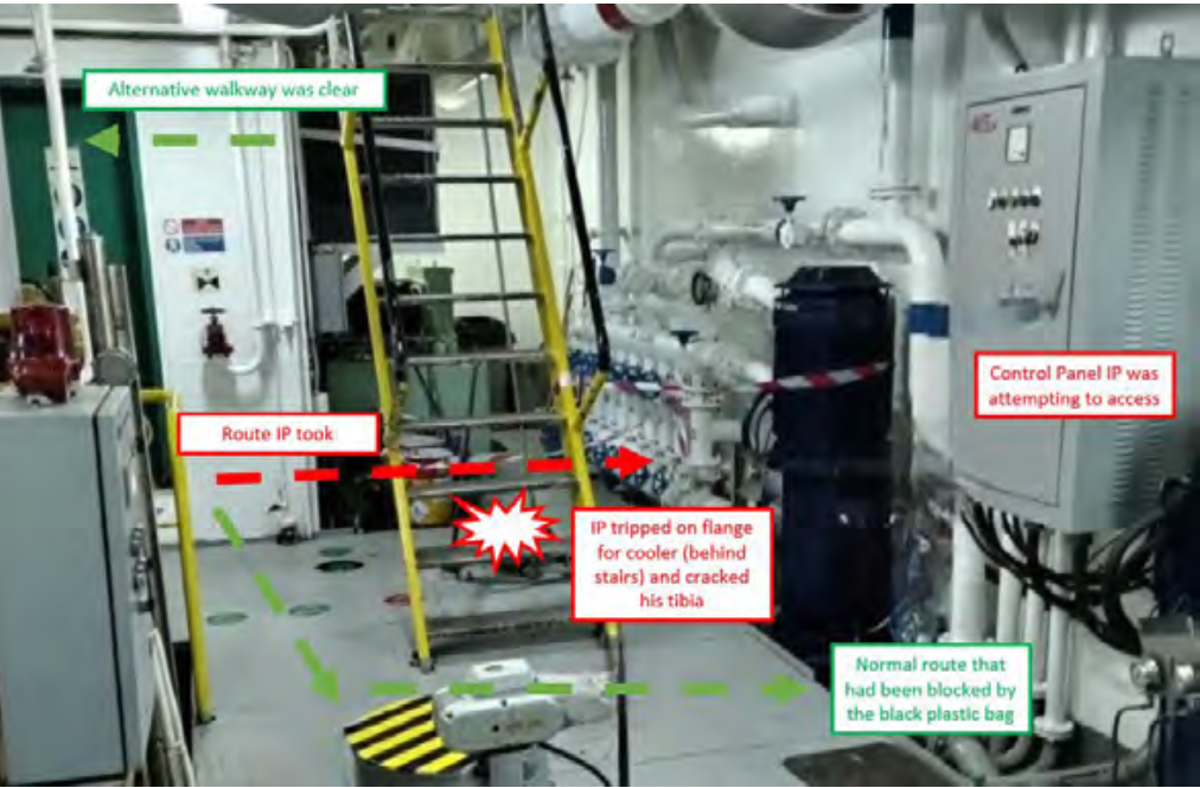

An engineer suffered a broken shin when he slipped taking a shortcut into the engine room.

He went into the engine room down some stairs, in order to access a control panel, and found that access to the control panel was blocked by a plastic bag installed to collect paint chippings from maintenance work on the stairs.

He took an alternative route behind the staircase, hit the stairs with his right shoulder, and lost his balance.

He fell in such a way as to hit his ankle on a valve on the floor of the engine room, causing a cracked tibia (shin bone).

Lifeboat

What went wrong?

- No-one stopped to think:

- Maintenance work created new, additional hazards – the crew conducting the maintenance work had blocked the walkway.

- There were no barriers or controls in place to stop anyone from using the stairs being maintained, nor was the available alternative route highlighted.

- The crew doing the maintenance work had not communicated what they were doing to the engineers.

- The engineer took an unnecessary shortcut when there was an easily accessible walkway to the control panel.

- Maintenance work created new, additional hazards – the crew conducting the maintenance work had blocked the walkway.

- None of the above was identified in any risk assessment or pre-job toolbox talk.

Lessons learnt

Our Member noted the following learnings

- Understand the need for thorough risk assessment that identifies all potential hazard including that which might arise from maintenance work.

- Ensure effective communication is in place between departments, shifts, crews etc especially with regard to blocked access, maintenance, and any simultaneous operations going on.

- Ensure proper signage and physical barriers are in place where required during maintenance work.

- Take FIVE…STOP!! Think and look again. Remember you have a right and a duty to STOP THE JOB it if it is unsafe.

Related safety flashes

-

IMCA SF 02/20

10 January 2020

-

-

IMCA SF 13/18

22 June 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.