Well drilled in the wrong place breaches railway tunnel

- Safety Flash

- Published on 1 July 2019

- Generated on 22 January 2026

- IMCA SF 15/19

- 2 minute read

Jump to:

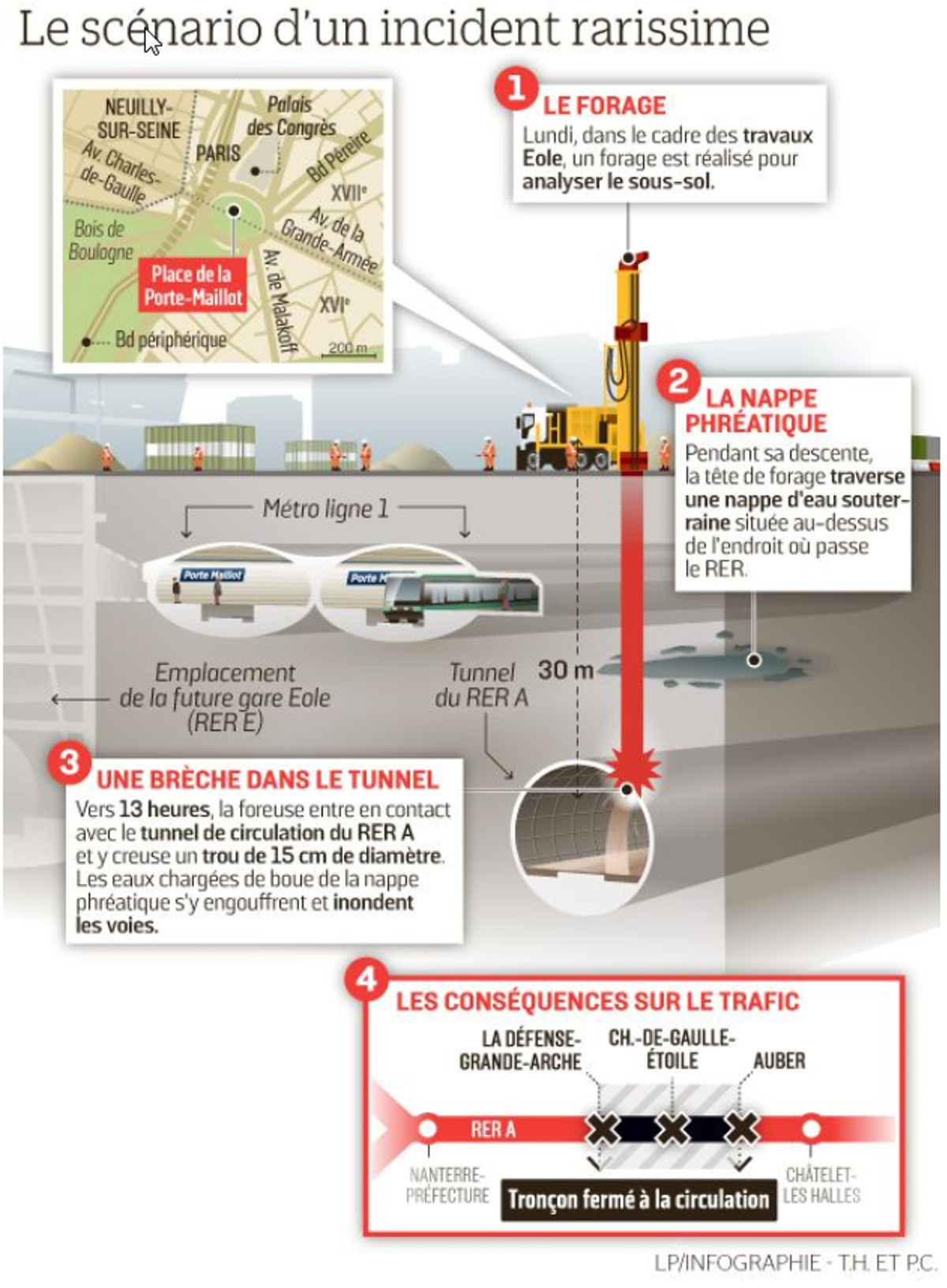

At a large construction site in a big city, contractors drilled an exploratory well in slightly the wrong place and as a result drilled into the wall of a busy railway tunnel, closing the railway for three days.

What happened?

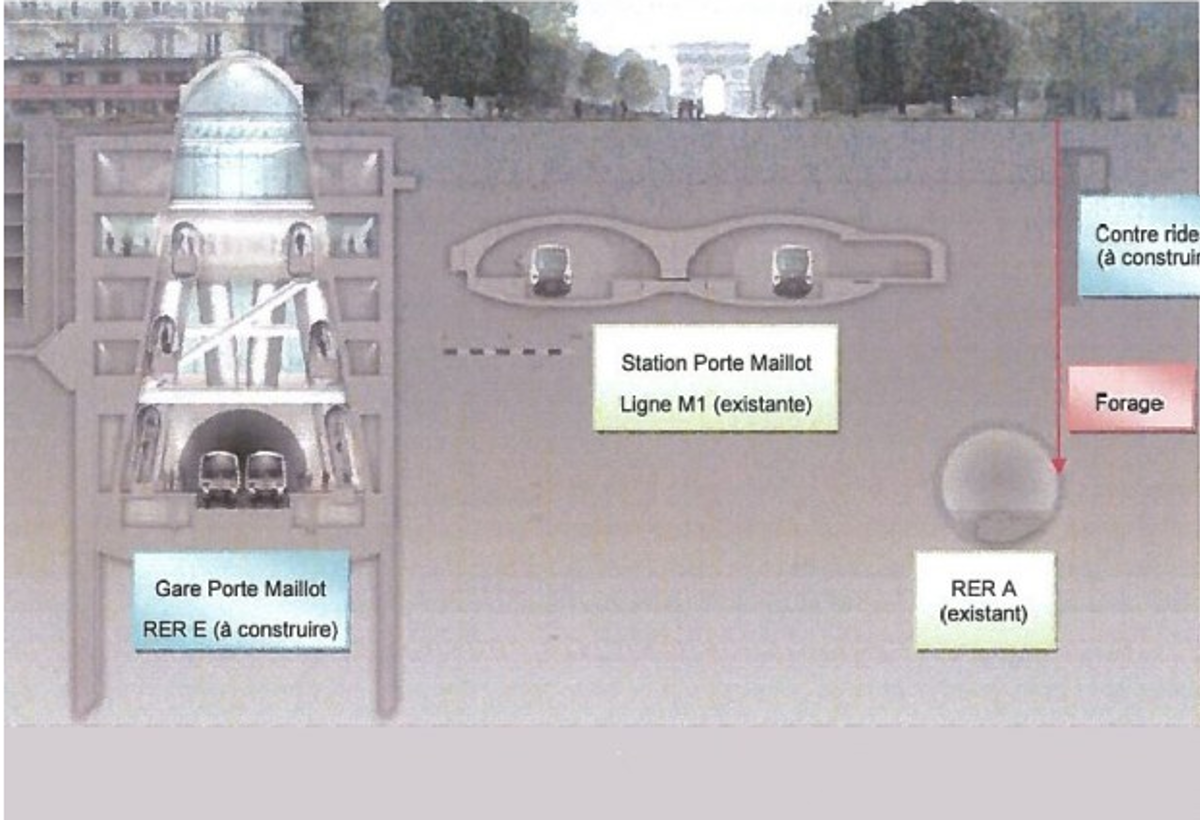

The incident occurred during the construction of an extension to an underground railway line in Paris. The well was drilled for civil engineering/geological test purposes by the consortium of contractors in charge of the project.

The well was drilled through the water table, and when the drill bit penetrated the railway tunnel, there was an inrush of ground water and mud into the tunnel. Within a few hours, this had reached a volume of 40 cubic metres. The RER A - the busiest urban railway line in Paris - was closed for three days as a result.

There were no injuries or casualties.

What went wrong? What were the causes?

- The decision to drill the well was made by the contractors without the approval of the client.

- The positioning of the well was conducted without the control and validation of a surveyor. The official report noted: [translated from the French]

"The lack of intervention of a surveyor resulted in an error which was sufficient to lead to the accident"

What lesson was learned?

- Ensure that appropriate technical and professional advice is sought from surveyors for all operations requiring any type of positioning.

The French government report into the incident (in French) Expertise sur la maitrise des risques des travaux en souterrain, premier rapport suite a l’incident de chantier du 30 octobre 2017* is available here.

* [Risk management in underground works – initial report following construction incident of 30 October 2017]

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.