LTI: Finger injury sustained handling heavy shackle pin

- Safety Flash

- Published on 2 June 2017

- Generated on 4 March 2026

- IMCA SF 13/17

- 2 minute read

Jump to:

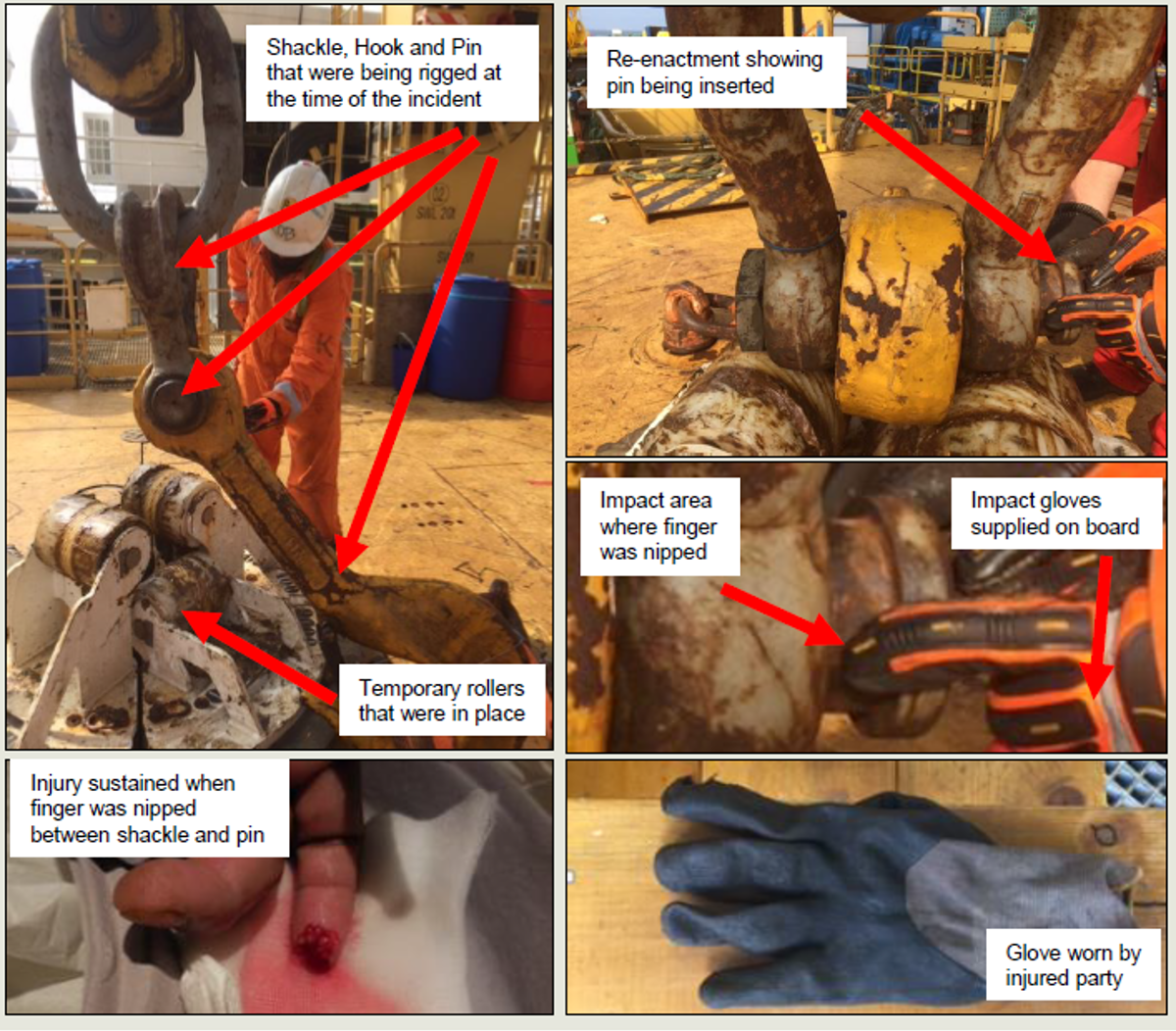

During re-rigging of heavy lifting gear, two riggers were holding the crane hook upright, another three were holding the shackle, and a sixth crewman was holding the shackle pin ready for insertion.

What happened?

As the sixth crew member pushed the shackle pin home, his left index finger was nipped between the head of the shackle and the body of the shackle.

This resulted in a serious injury to the index finger of the left hand.

What were the causes of the incident?

Our member identified the following immediate causes:

- Not paying attention – lack of awareness of hazards; this was due to the routine nature of the activity.

- Inadequate personal protective equipment (PPE) – impact-resistant gloves not worn; these could have reduced the severity of the incident.

The following underlying causes were identified:

- Complacency – due to the repetitive nature of this routine activity.

- Prescribed PPE was not worn due in part to poor communication and poor enforcement of the requirements.

- Poor design of the shackle pin and the method used for rigging may have contributed to the incident – the size and shape of the pin head left little room for the fingers to hold.

- Environment – the work area was restricted and cramped.

What lessons were learned? And what were the actions?

- Easier rigging arrangements involving less manual handling would be investigated, including the possible use of mechanical aids.

Related safety flashes

-

IMCA SF 04/16

5 February 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.