Crane boom stopper fell to main deck

- Safety Flash

- Published on 16 May 2023

- Generated on 13 December 2025

- IMCA SF 12/23

- 2 minute read

Jump to:

A knuckle boom stopper pad fell to the main deck directly below the knuckle boom; no personnel were injured - however, there was potential for serious or fatal injury.

What happened?

A knuckle boom stopper pad fell to the main deck directly below the knuckle boom. No personnel were injured, however there was potential for serious or fatal injury.

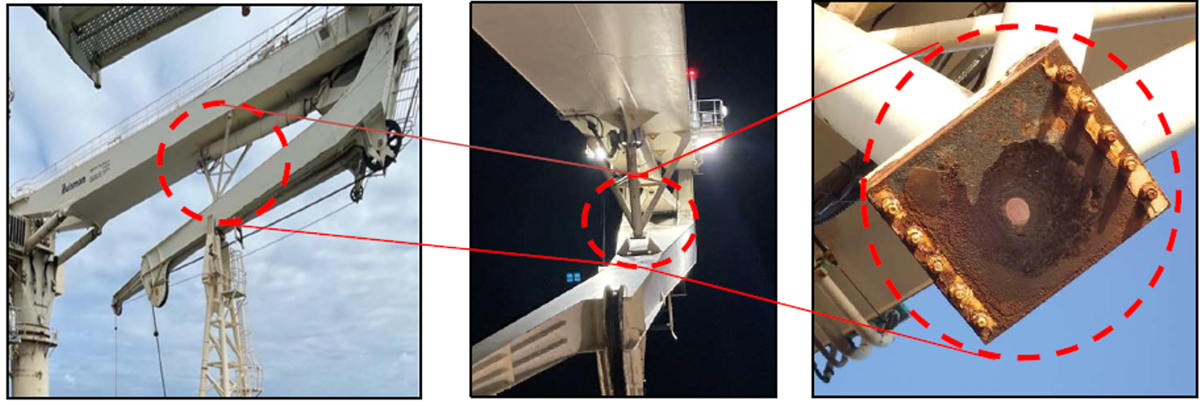

The incident occurred when a crane operator started moving the crane boom in preparation for use. Once the crane was clear of all obstructions the crane operator started slewing it outboard.

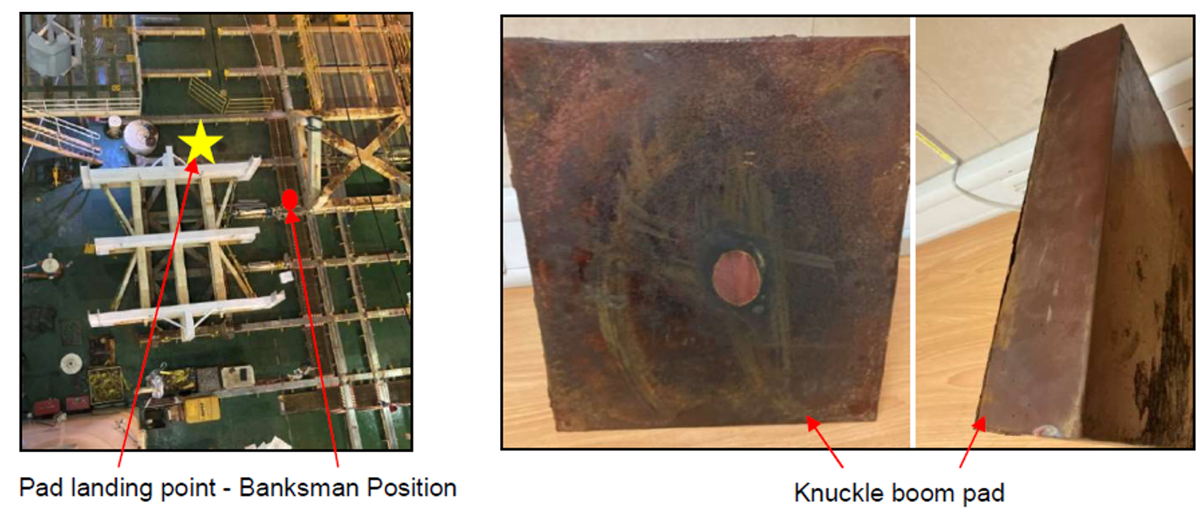

The rigging supervisor acting as banksman was in attendance, located on the inboard dedicated walkway. As the crane boom was slewing, the crane operator saw the boom stopper sliding down the knuckle boom and then falling to the deck.

The crane operator immediately sounded the crane horn. The boom stopper weighed 15.5 kg and fell 35 m.

There were no personnel near where it dropped/landed.

Investigation

- The area where the knuckle boom stopper pad landed was not a restricted area, access up and down the deck was via a dedicated walkway, inboard of the boom, 5 m away from where the boom stopper landed.

- The knuckle boom stopper pad was only attached to the backing plate by adhesive and then the backing plate bolted to the boom stopper frame structure.

Actions

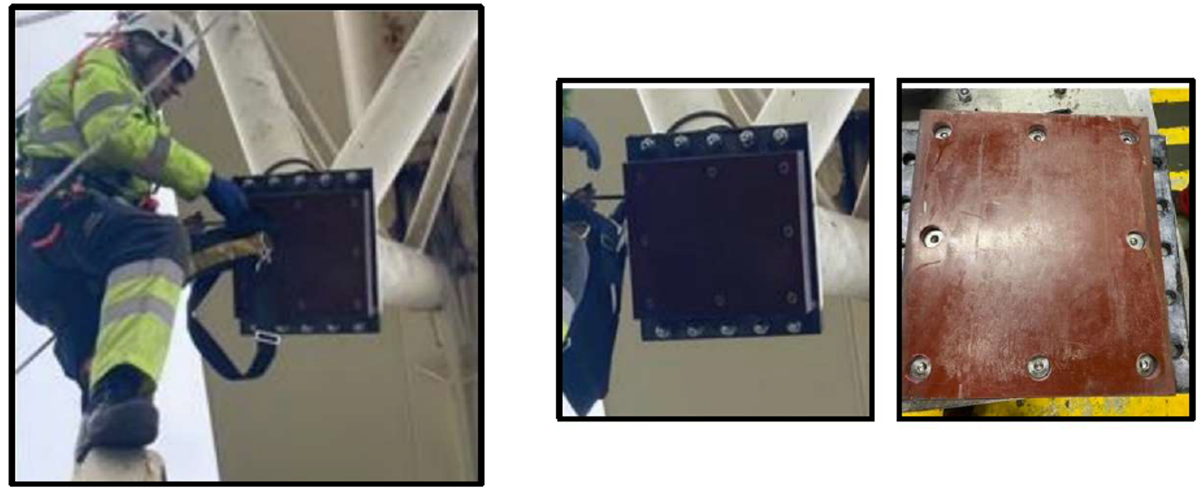

- Vessel technicians modified the backing plate by securing the boom stopper pad with 8 x M16 countersunk cap screws, Loctite and centre dab, and then it was reinstalled by a rope access team.

- The metal backing plate was secured with M20 bolts using nyloc and Loctite, preventing any repeat of the boom stopper becoming detached.

- There is potential for similar incidents to happen on other vessels, in areas where access to potential dropped objects is difficult. Check and see:

- If any other cranes use the same or similar type pads and if so, ensure alternative or additional fixings are applied to any connections solely reliant on adhesive compound bonding.

- Identify equipment and structures that present a risk of dropped objects and cannot be easily accessed for inspection and determine the best means of safe access and an appropriate frequency of inspection.

- Verify if there is an existing work order or dropped object check list to cover these items and add/update as necessary.

- If any other cranes use the same or similar type pads and if so, ensure alternative or additional fixings are applied to any connections solely reliant on adhesive compound bonding.

Related safety flashes

-

IMCA SF 10/21

8 April 2021

-

-

IMCA SF 05/20

13 February 2020

-

-

IMCA SF 16/16

27 June 2016

-

IMCA SF 10/15

16 July 2015

-

IMCA SF 04/11

19 April 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.