Close approach of AHTS vessel to offshore rig

- Safety Flash

- Published on 16 May 2023

- Generated on 16 February 2026

- IMCA SF 12/23

- 2 minute read

Jump to:

An AHTS vessel made a close approach to the mooring lines for an offshore rig.

What happened?

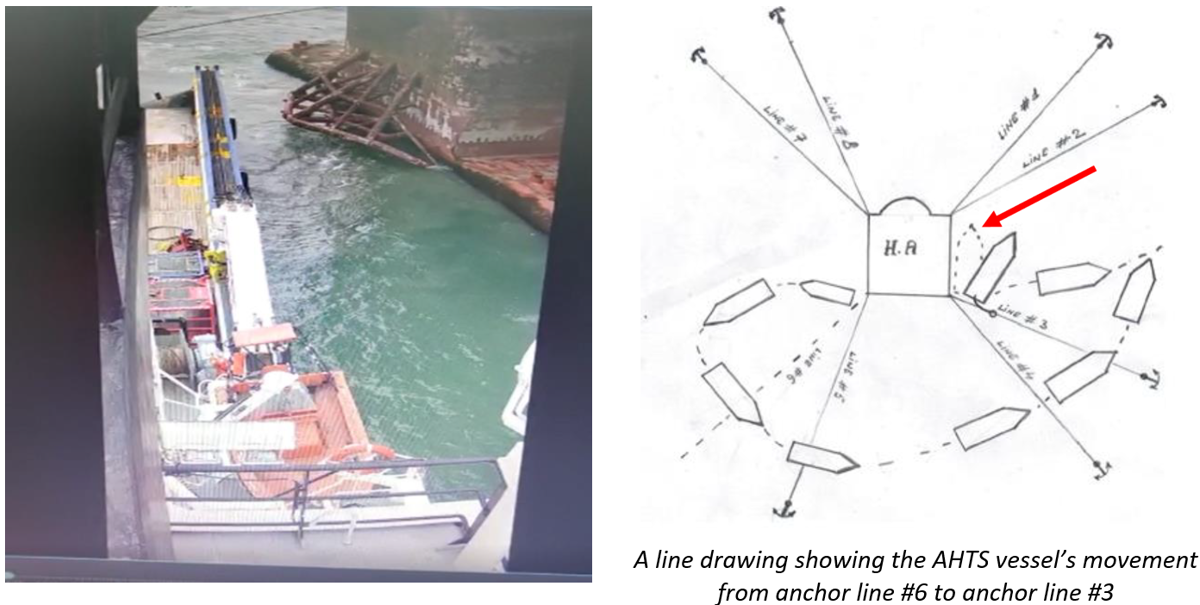

The AHTS was involved in anchor handling operations for the rig. The vessel passed anchor line #6 to the rig and started to move towards anchor line #3.

Control of the vessel was transferred from forward to aft console. Once in position, the vessel received the PCP (Permanent Chasing Pennant) of anchor line #3 by rig crane and it was secured on the Karm fork.

The rig’s crane was released, but the chaser’s collar slid on the anchor line towards anchor #3 and pulled the stern of the vessel to starboard, resulting in a bow side close approach to mooring line #2.

To stop this movement the Master activated the bow tunnel thruster, but the thruster did not start. As a result, the vessel bow had a close approach to mooring line #2. The Master immediately switched on all thrusters, obtained full manoeuvrability of the vessel, and the vessel pulled away safely.

What was the cause?

- Further review identified that the bow thruster electromotor was off. Machinery required for safe manoeuvring of the vessel had been disabled. The electromotors for the tunnel thrusters had been switched off by the chief officer to rest the machinery as the vessel was leaving the 500m zone. This fact had not been communicated to the Master.

- The fact that the servo pumps were running gave a false assurance of full operability of the thrusters.

- There was no check of full operability after transfer of vessel control from forward to aft control stations.

Actions

- Ensured that critical vessel equipment is not switched off or its operational mode changed without the approval of the person in charge on the bridge.

- Manual transfer of vessel control to be followed by mandatory thorough checks of all propulsion relevant to the operation.

- Developed comprehensive work instructions for bridge transfer control.

Related safety flashes

-

IMCA SF 07/22

22 March 2022

-

IMCA SF 10/21

8 April 2021

-

IMCA SF 07/17

28 March 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.