Update to SF 08/21: Fatality – person crushed when secured material fell on him

- Safety Flash

- Published on 27 April 2021

- Generated on 30 December 2025

- IMCA SF 12/21

- 4 minute read

Jump to:

This is an updated version of the event published in SF 08/21, wherein stored metal plates fell on a crewman causing fatal injuries. It was originally shared with one of our members by a client company, and was public domain news. It does not involve an IMCA member. This updated version has been shared by the company involved.

What happened?

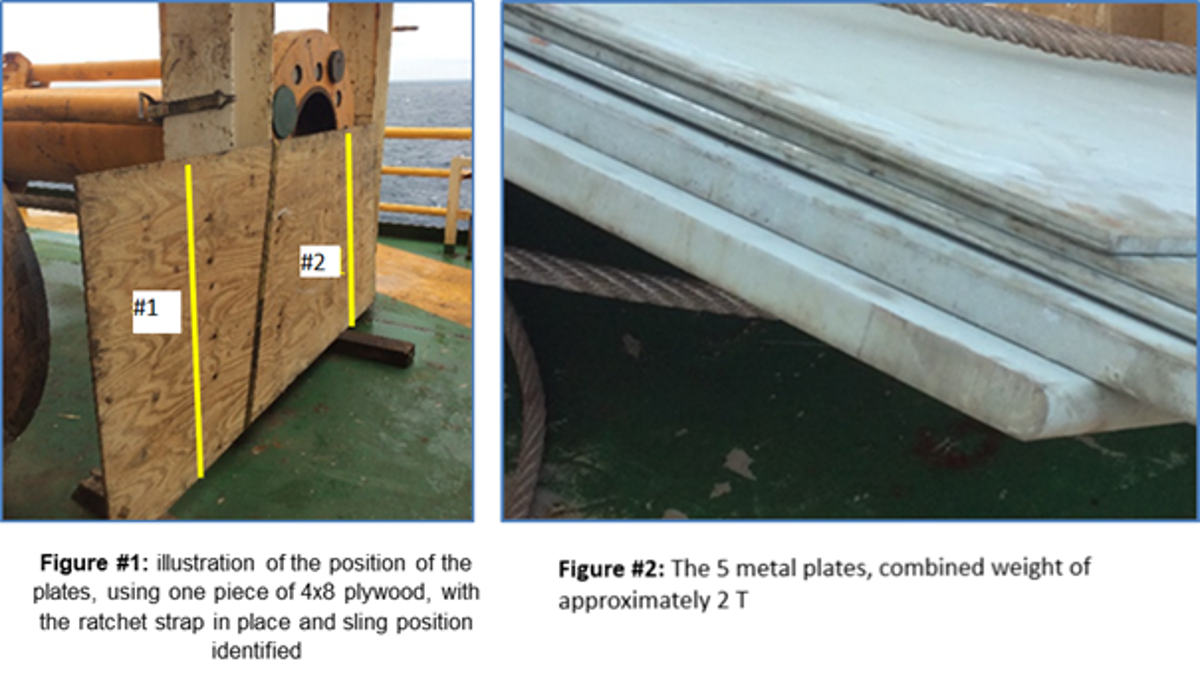

An inspection team leader and his assistant were performing loose lifting gear inspections on deck. The task was visually inspecting slings, recording serial numbers and applying the current colour code. During the inspection, the inspection team leader observed two slings rigged up to a load of metal plates which were stacked vertically, resting on dunnage, and secured to a stanchion by a single 5cm ratchet strap.

The slings had been left in place on the plates after they were landed by the crane for efficiency and ease of relocation when needed. The plates were all 48 x 96 cm, varying in thickness between 10 mm and 25 mm, with a combined weight of two tonnes.

The inspection team leader attempted to, and was successful in, sliding one of the slings from the plates on the inboard side (#1 represented above in Figure #1), but he discovered the second sling (#2 represented above in Figure #1) was pinched between the rear of the plates and the stanchion, preventing it from being taken off on the outboard side.

He then called his assistant to help free the sling, and remove it for inspection.

What went wrong?

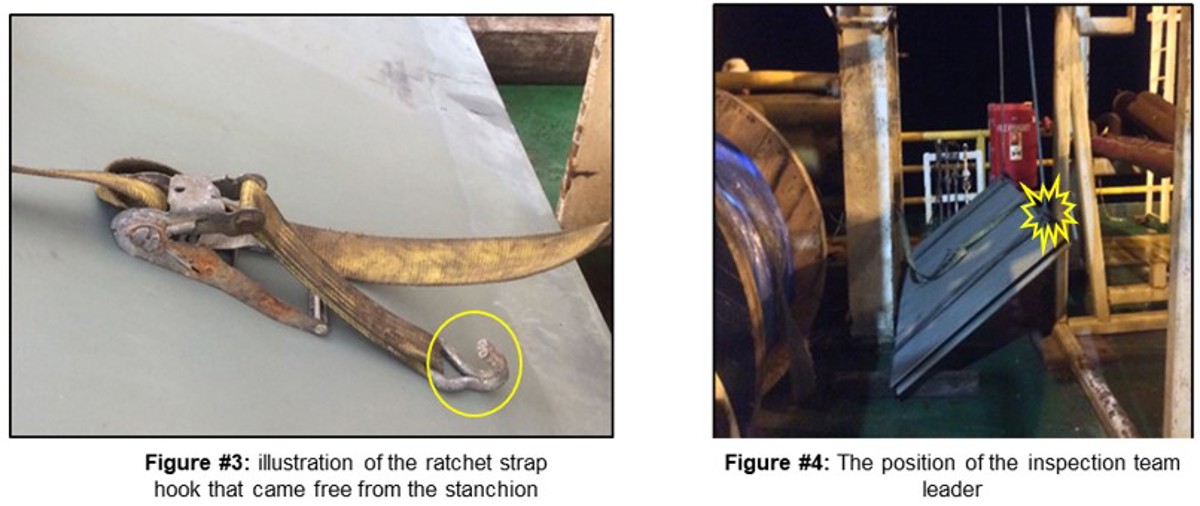

The inspection team leader then leaned his back against the plates; the reason for this is unknown, but it is assumed the intention was to support the plates in their standing position when the ratchet strap was loosened. When he was standing in this position, directly in front of him was a framework for the drilling bail rack. When the ratchet strap was manipulated by the assistant, the hook (ratchet strap) released (see Figure 3), allowing the plates to free fall forward (away from the stanchion) under their own weight, fatally trapping the inspection team leader between the plates and the framework of the drilling bail rack (see Figure 4).

The weight of the falling metal plates overwhelmed the inspection team leader, who was caught in the line of fire and pinned between the plates and the solid frame – and fatally injured. First responders arrived at the scene and attempted to manually remove the plates but were unable to due to their weight.

Actions

- Reinforce your awareness of the Line of Fire – watch out for getting between loads and structures.

- Improve risk perception and situational awareness.

- Remember you are allowed to STOP THE JOB if you think it is unsafe!

- Ensure tasks are clear and well planned. Discuss before hand, factors that might make stopping the job necessary.

- Recognise when the nature of a task changes, and manage that change safely. In this case, a low risk task of visually inspecting loose lifting gear changed to a much higher risk task without the team recognising they were deviating from their task – by removing rigged-up slings on sea-fastened cargo, the nature of the task and risk profile had changed.

- Are there sufficient measures in place to prevent unauthorised manipulation of sea-fastenings?

- Look at your housekeeping and sea-fastening:

- Are materials stored safely?

- Has the potential for unplanned release of stored energy been minimised as far as practical (e.g. if a strap comes loose, will the stored material fall or tip over?) Can this be mitigated by storing in an alternative location or an alternative orientation (e.g. by lying flat?)

- Are materials stored safely?

- Ensure third-party sub-contractors and other crew are fully integrated into daily operations management, toolbox talks, risk assessment etc.

- Could this have been designed out? Are deck designs sufficiently robust to take foreseeable equipment configurations – eliminating the need for materials to be required for temporary deck strengthening for specific operations?

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.