Chain hoist failure resulting in a serious near miss

- Safety Flash

- Published on 31 March 2020

- Generated on 25 April 2025

- IMCA SF 12/20

- 2 minute read

Jump to:

What happened?

During maintenance of a vessel’s main engine there was a requirement to remove the charge air cooler weighing 400 kg.

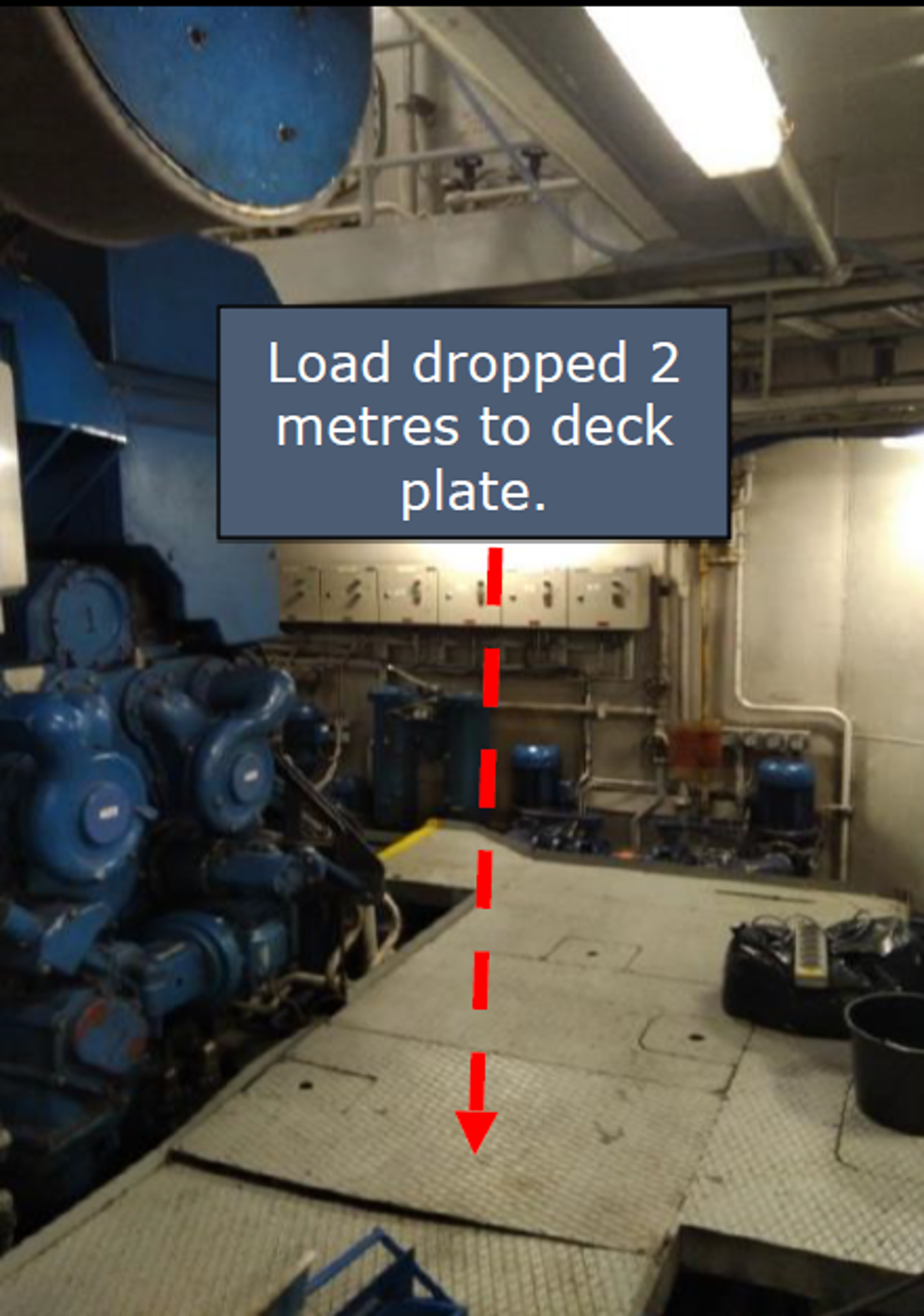

The third-party contractor who was tasked with the maintenance job was in the process of lifting the item when the (electric) chain hoist failed, resulting in the load dropping two metres to the engine room deck plating.

The chain hoist used for the vertical lift (SWL 500 kg) was permanently installed on an engine room running beam located specifically to facilitate this type of operation.

After the incident, the hoist was quarantined and analysed by a third-party specialist company in order to establish the cause of failure.

What were the findings?

The inspection and maintenance regime for the hoist was within date but was considered inadequate as it only involved a visual inspection and function test (without load).

The unit was infrequently used and was not subjected to internal inspection; this allowed the internal braking mechanisms to suffer corrosion, and this prevented the braking function operating properly when under load.

The above resulted in the clutch failing to hold the load, lowering the charge air cooler to the engine room deck plating in an uncontrolled and rapid manner.

Good planning and rigging practice were observed by the lifting team, personnel were in ‘safe zones’ during the lift and not in the line of fire. Slight damage to the deck plating was observed.

What actions were taken by our Member?

- Full inventory made of all powered hoists (pneumatic and electric) to include both chain hoists and wire hoists and not restricted to permanently installed units.

- Additional relevant maintenance scope added to planned maintenance scopes for all these devices.

- Powered hoists fitted with overload devices should be set at working load limit (WLL) +10% and checked annually as part of the planned maintenance regime.

Related Safety Flashes

-

IMCA SF 18/14

25 November 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.