Agitator started moving during mud tank cleaning – leading to injury

- Safety Flash

- Published on 31 March 2020

- Generated on 6 February 2026

- IMCA SF 12/20

- 3 minute read

Jump to:

What happened?

An agitator in a mud tank started up when an employee of a third-party contractor working in the tank was in the way. He was hit by the agitator paddle in his lower back and fell to the tank floor.

The contractor came on-board to wash mud tanks with a high-pressure washer. Mud tanks on the vessel had been emptied earlier in the day and agitators were running until the tanks were empty.

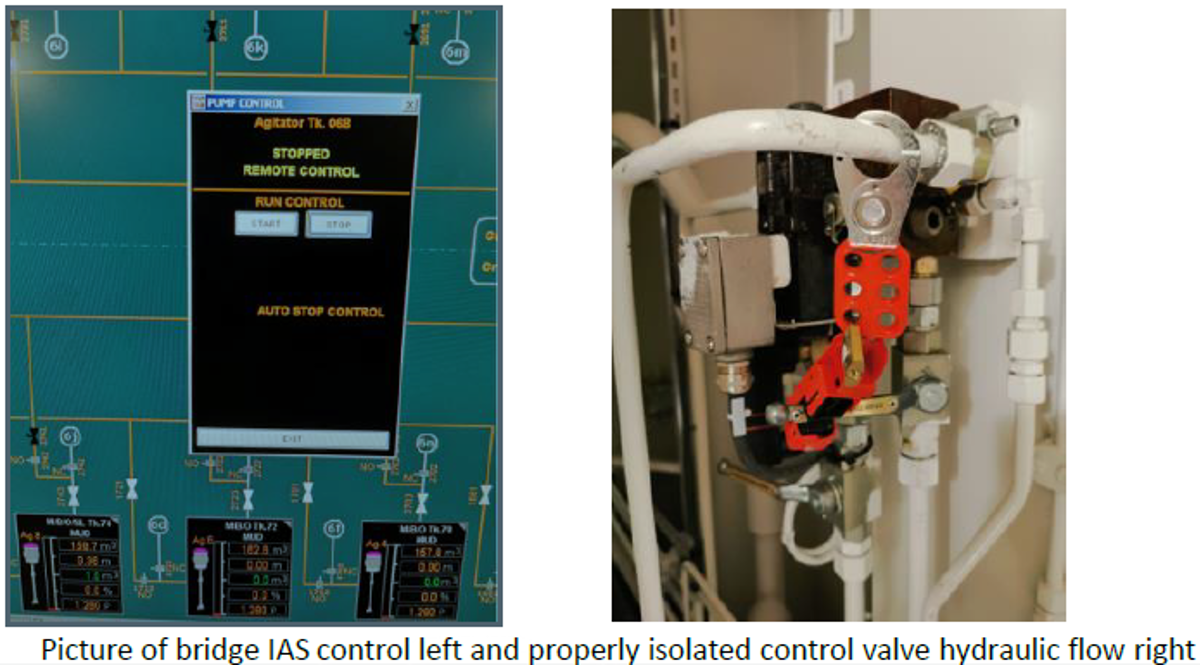

The agitators were stopped on bridge IAS only and had not been isolated or locked out.

As the last of three tanks was being washed, the agitator (42 rpm) suddenly started with one person inside the tank.

The person was hit by the agitator paddle in his lower back and fell to the tank floor. He had his back to the agitator at the time and didn’t notice it starting. He managed to climb out of the tank by himself and was transported to hospital by ambulance. He was discharged the same day with bruises and one broken rib.

What were the causes?

Investigation found several direct and contributing causes for the incident:

- Procedures concerning isolation of moving or rotating equipment were not followed:

- Isolation of the agitator was simply forgotten even though there was no rush to start work, nor were the bridge crew particularly busy.

- An isolation certificate was consequently never issued.

- There were no properly implemented routines for isolation when initiated by bridge.

- Risk assessment contained check of isolation, but was not thoroughly reviewed.

- The third-party company had in their procedures to verify/check isolation, but this was not done as this was considered a vessel responsibility.

- There was not full involvement of the engine department in tank washing operations, as isolation requests were usually initiated on the bridge, i.e. they had no independent sense of responsibility and merely acted on bridge initiative to isolate equipment.

- The agitator started by itself, for as yet unknown reasons. Investigation is ongoing as to the technical cause, but this is considered less important as the incident would never had happened had the agitator been isolated as per procedures.

What actions were taken?

- Physical verification that safety isolations and barriers, controls and lockouts are in place – double check.

- Focus on how to improve compliance with existing procedures.

- Review relevant risk assessment.

- Better communication between bridge department and engine department, particularly relating to tank maintenance operations.

- Improve isolation routines to include lock and tag and issuance of isolation certificate.

- Third-party tank washers will improve their procedure to include physical verification that agitators are properly isolated before entering tank.

Related Safety Flashes

-

IMCA SF 12/15

28 August 2015

-

IMCA SF 07/08

10 April 2008

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.