Maintenance and painting – two incidents

- Safety Flash

- Published on 4 May 2022

- Generated on 14 February 2026

- IMCA SF 11/22

- 2 minute read

Jump to:

A member reports two incidents in which something went wrong owing to failures in the maintenance process.

Incident 1: Material failure during lowering of lifeboat

During lowering of a lifeboat, a small shackle broke. The shackle held the upper sheave guiding the brake release wire, resulting in the sheave falling down on top of the lower sheave. This caused the brake handle not to fall into brake position, with the consequence that the lifeboat did not stop lowering but kept on going down.

What went right?

The situation did not get out of control: the officer on deck took over control and applied force on the brake handle to stop the boat going any further down. There were no injuries in either incident.

Photo 1

Brake release wire drum overpainted

What went wrong?

Investigation showed that that the brake release wire drum was stuck/not turning, apparently due to there being an excessive amount of paint (see illustration) applied during the recently done maintenance. Once the paint was removed, the drum could be easily moved by hand.

Incident 2: Damaged sheave due to main hoist high hook failure

The main hoist hook block overshot the highest position alarm and ran into the sheaves from the main runner under the jib. The jib was lifted by the force of the main runner and the crane stopped automatically when the slack wire alarm of the topping wire was activated.

What went wrong?

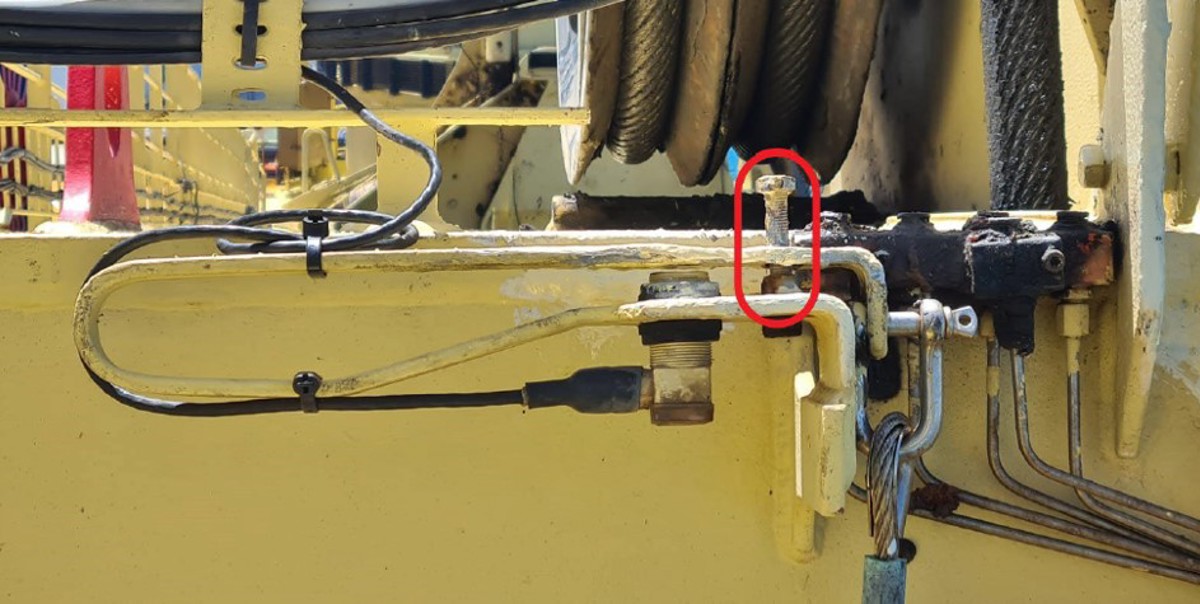

Investigation showed that one of the runner sheaves underneath the jib was bent slightly and unable to move freely. During the inspection of the high hook alarm, it was discovered that the flat bar (see illustration) in front of the sensor was not moving. It was stuck in place because of dry paint from maintenance that morning.

Further, the crane operator did not pay sufficient attention when working near the limits of the crane, not looking up to the hook.

Swipe to see images >

Actions

- The damaged sheave was reshaped. Thorough examination of the sheave surface and inspection by means of dye penetration testing showed that there were no cracks.

- Ensure close monitoring the crane movements after each order given and when working near any of the crane limits.

- Test alarms after maintenance on the crane.

- After maintenance/painting check that all equipment parts are still movable and fully operational.

Related Safety Flashes

-

IMCA SF 34/21

9 December 2021

-

IMCA SF 21/18

17 September 2018

-

-

IMCA SF 05/21

11 February 2021

-

IMCA SF 05/21

11 February 2021

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.