High potential near-miss: Incorrectly secured overhead equipment

- Safety Flash

- Published on 22 May 2017

- Generated on 10 January 2026

- IMCA SF 11/17

- 2 minute read

Jump to:

During operations, it was observed that the connecting shackle pins on two separate items of overhead equipment (fall arrest inertia reels) were loose and could have become detached.

Had any of this equipment fallen, it could have struck someone underneath with potentially fatal consequences.

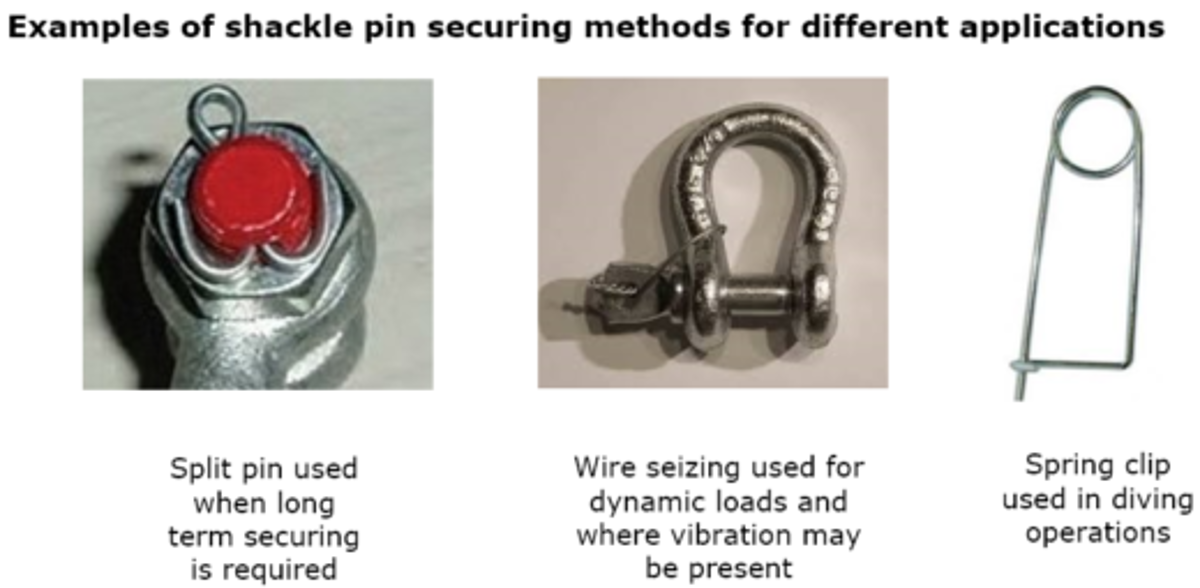

R-clip type that was incorrectly used for this application but is commonly used in diving operations

Findings

- Inspection of the securing arrangements revealed that the wrong securing clips had been used and these had fallen out, enabling the shackle pins to work loose. A split pin or wire seizing should have been used to secure the shackle pin.

- The equipment was covered by weather protection boxes which prevented easy inspection of the securing arrangement.

This incorrect securing arrangement was identified previously but lessons were not shared across the fleet or with the contractors who installed this equipment.

Actions

- Conduct a hazard hunt to confirm that any overhead equipment is secured correctly to prevent it coming loose.

- Visual check of rigging and securing of any man riding or fall arrest equipment for similar issues.

- Ensure appropriate regular inspection regimes are in place, particularly for locations where visual inspection is difficult – consideration should be given to equipment already positioned at height or concealed from view.

- Users of fall protection devices may not be able to visually inspect the connections because of location or if weather protection devices are used. In these cases, additional or other suitable inspection arrangements should be in place.

- Care should be taken to confirm the adequacy of the securing arrangements applied when third parties are engaged to install, maintain or inspect such equipment.

Related safety flashes

-

IMCA SF 02/15

5 February 2015

-

IMCA SF 18/13

20 December 2013

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.