Near Miss: Personnel nearly struck by rotating chain attached to flexible pipe

- Safety Flash

- Published on 20 April 2023

- Generated on 4 February 2026

- IMCA SF 10/23

- 2 minute read

Jump to:

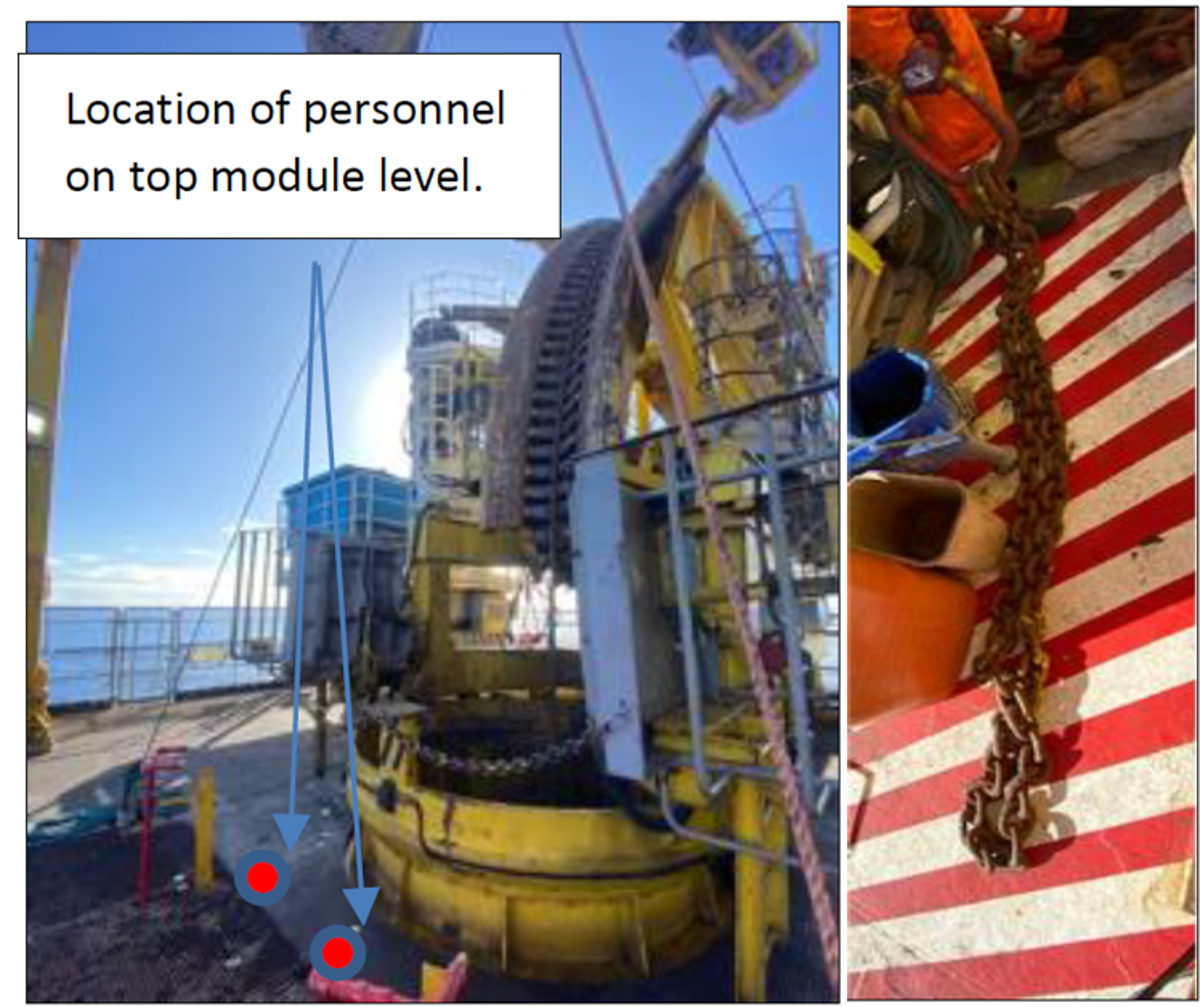

Crew were involved in the second end transfer of a 4″ (10cm) production flexible up to the top module of the pipelay system.

What happened?

As the second end was being transferred, the tensioners were in the following position: upper tensioner – open, lower tensioner – closed.

To allow the weight to be transferred onto the A&R wire the lower tensioners were opened.

This then resulted in the production flexible rotating due to the residual torsion that had been built up within the line.

A 16.5te chain used for the transfer of the second end was still attached to the pull-in head, as the flexible pipe began to rotate, this chain also spun.

Two crew members who were observing the operation were stood nearby and were almost struck by the spinning chain.

What was the underlying cause?

- Key people involved were inexperienced in this specific activity and were not familiar with the task in hand

- There was a failure to identify the risk posed from the chain still being attached to the flexible pipe.

- There was a language barrier:

- Some of the team were unable to speak English.

- The Task Risk Assessment for this operation was only available in English.

- Some of the team were unable to speak English.

- The procedure did not identify when the chain should be removed nor other mitigation measures.

Lessons learned

- Ensure important documentation such as Task Risk Assessment, procedures and checklists are available in the languages of the crew doing the work.

- Ensure it is specified in procedures or checklists when rigging or any other items are to be attached or removed.

- Always remove the rigging after transferring loads to the A&R; when removal of rigging is not possible, suggest additional mitigation actions in the Task Risk Assessment.

- One mitigating measure was to install a gate with signage restricting access to the top module.

Related safety flashes

-

IMCA SF 07/23

13 March 2023

-

-

IMCA SF 34/20

16 December 2020

-

-

IMCA SF 11/18

4 June 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.