Communications: LTI finger injury during lifting operations

- Safety Flash

- Published on 21 April 2022

- Generated on 16 February 2026

- IMCA SF 10/22

- 2 minute read

Jump to:

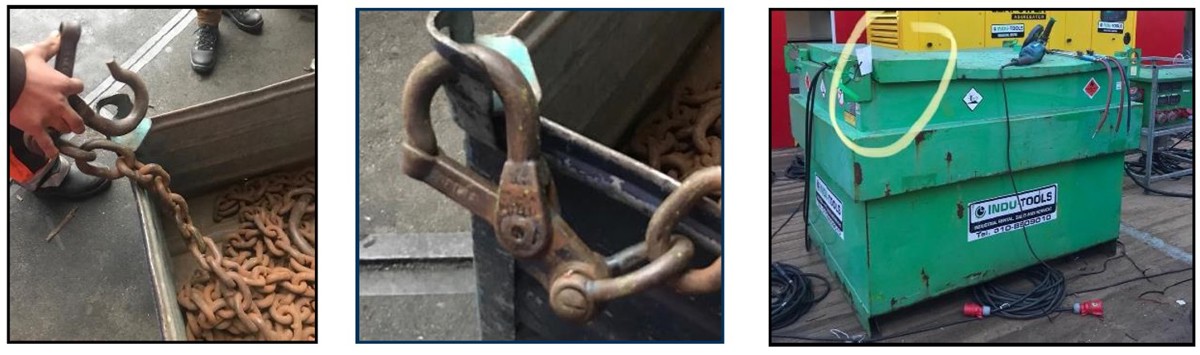

During demobilization lifting operations, a rigger’s right ring finger was crushed between the crane hook and a lifting eye.

What happened?

A vessel was demobilizing with a third party crane operator and banksman hired to perform lifting activities moving items on deck. A Toolbox Talk (TBT) was held before operations started. A container was being lifted from the vessel to the quay, using a quayside crane. The container was lifted and set down on the quay, and crew detached the rigging from the container lift points. Three of the hooks were loose and on top of the container and one hook was still attached to the container lifting eye, when the crane operator started hoisting. The rigger foreman’s finger got jammed between the top of the hook and the top of the container lifting eye. His right ring finger was crushed between the hook and the lifting eye still attached. Surgery was required to amputate the fingertip.

What went wrong?

- The injured person had his hands on the crane hook.

- Miscommunication: the third party crane operator thought the company rigger foreman gave the signal to hoist. However, both the company rigger foreman and lift supervisor assert that the hand signal to lower the load was given.

- Our members’ investigation found that:

- Roles, responsibilities, communication, and risks during lifting operations were not discussed during toolbox talk (TBT).

- The toolbox talk was held in English and translated into another language for the third party crane operator who did not speak English.

- There was inadequate lift planning.

- The banksman remained on the quayside during the lifting operations and had no view of the lift and did not take control; the company rigger foreman (the injured party) took over the role of banksman. The hand signal that was given remains unclear.

- The gloves worn by the rigging crew did not have the required impact rating.

- Demobilization was not included in the project management plans or project bridging document.

Actions

- Agree and understand roles, responsibilities, and communication protocols before starting work.

- Ensure that EVERYONE involved understands what is going on, and that they have confirmed that understanding back to you in a satisfactory way.

- Ensure there is a clear lift plan available for routine lifts.

- Ensure mobilization and demobilization activities are included and clearly defined in project documentation and corresponding risk assessments.

Related Safety Flashes

-

IMCA SF 25/18

9 November 2018

-

-

IMCA SF 28/16

18 October 2016

-

IMCA SF 28/17

7 November 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.