Near-miss: Incorrect rigging of life raft hydrostatic release

- Safety Flash

- Published on 12 May 2017

- Generated on 13 January 2026

- IMCA SF 10/17

- 2 minute read

Jump to:

IMCA’s attention has been drawn to a near miss in which it was found that the hydrostatic release on a life raft was not correctly rigged.

What happened?

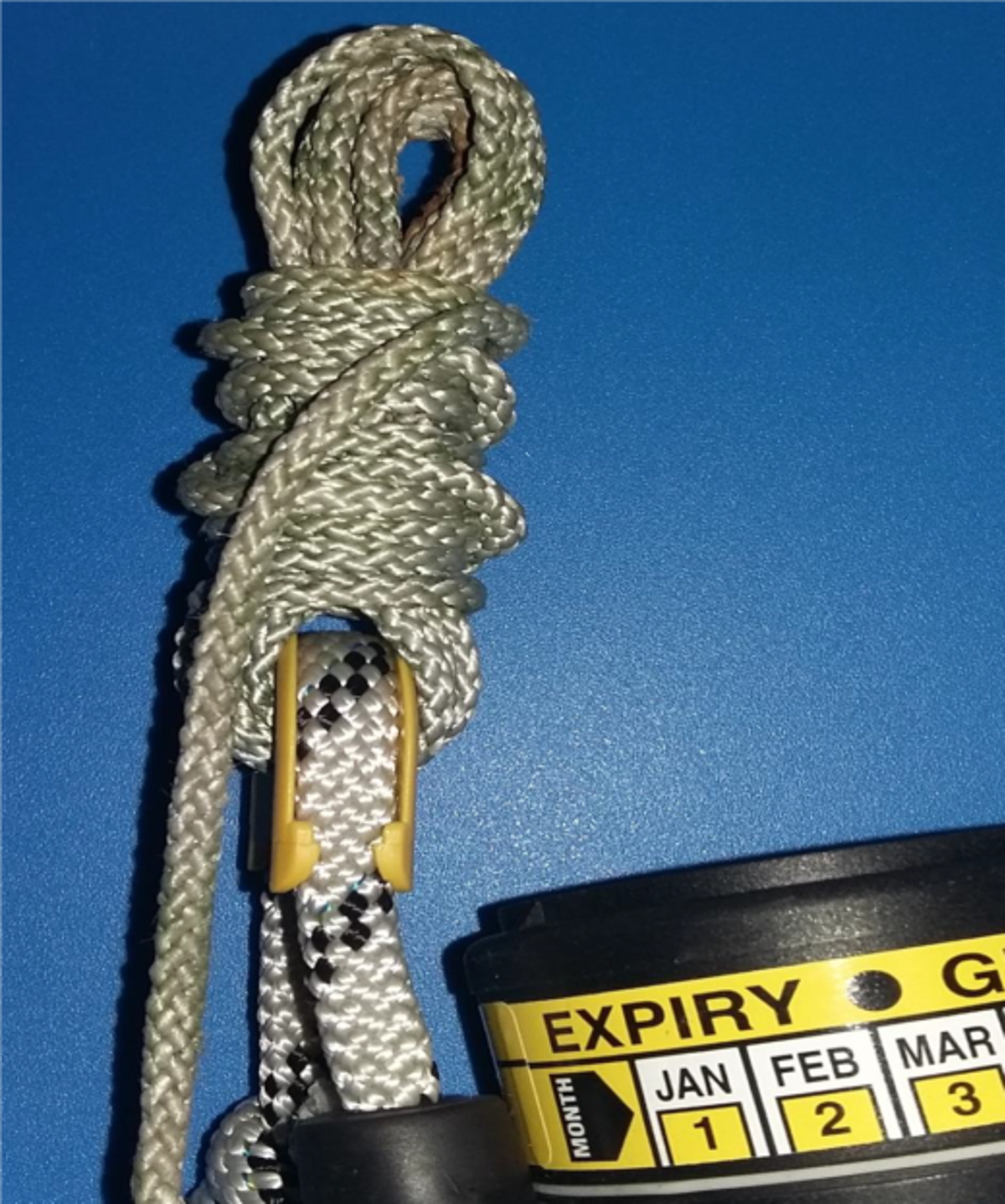

The incorrect rigging was discovered following the replacement of a life raft. It was noticed that if the collar on the Senhouse slip was lifted for life raft launch, it would not release the strap as the lashing that connected it to the hydrostatic release unit was tied too tightly, so the arm would not easily slip through and release.

This was due to the hitches in the lashing being carried on too far up towards the slip, not leaving enough room for the arm of the slip to move sufficiently.

lashing tied too tightly where usually connected to Senhouse slip

Recommendations

The following points are to be noted:

- The Senhouse slip should not be attached through a lashing and should be directly attached to the hydrostatic release unit.

- Hydrostatic release units are fitted with a yellow plastic that aids the release of the Senhouse slip when released. If fitted through a lashing, this can create friction making the operator unable to launch the life raft safely.

- The lashing can still be used in the securing of the life raft, but in a different position. Care should be taken to ensure that the painter line is tied through the red ring on the hydrostatic release unit.

Further information on correct securing of life rafts can be found in the UK Marine & Coastguard Agency (MCA) Marine Guidance Note 343.

correctly stowed HRU on life raft

incorrectly rigged HRU

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.