Lifting wire strop failure during air bag lift

- Safety Flash

- Published on 23 August 2006

- Generated on 25 December 2025

- IMCA SF 10/06

- 3 minute read

Jump to:

A Member has reported the following incident, which occurred during a diving operation from a DP diving support vessel.

What happened?

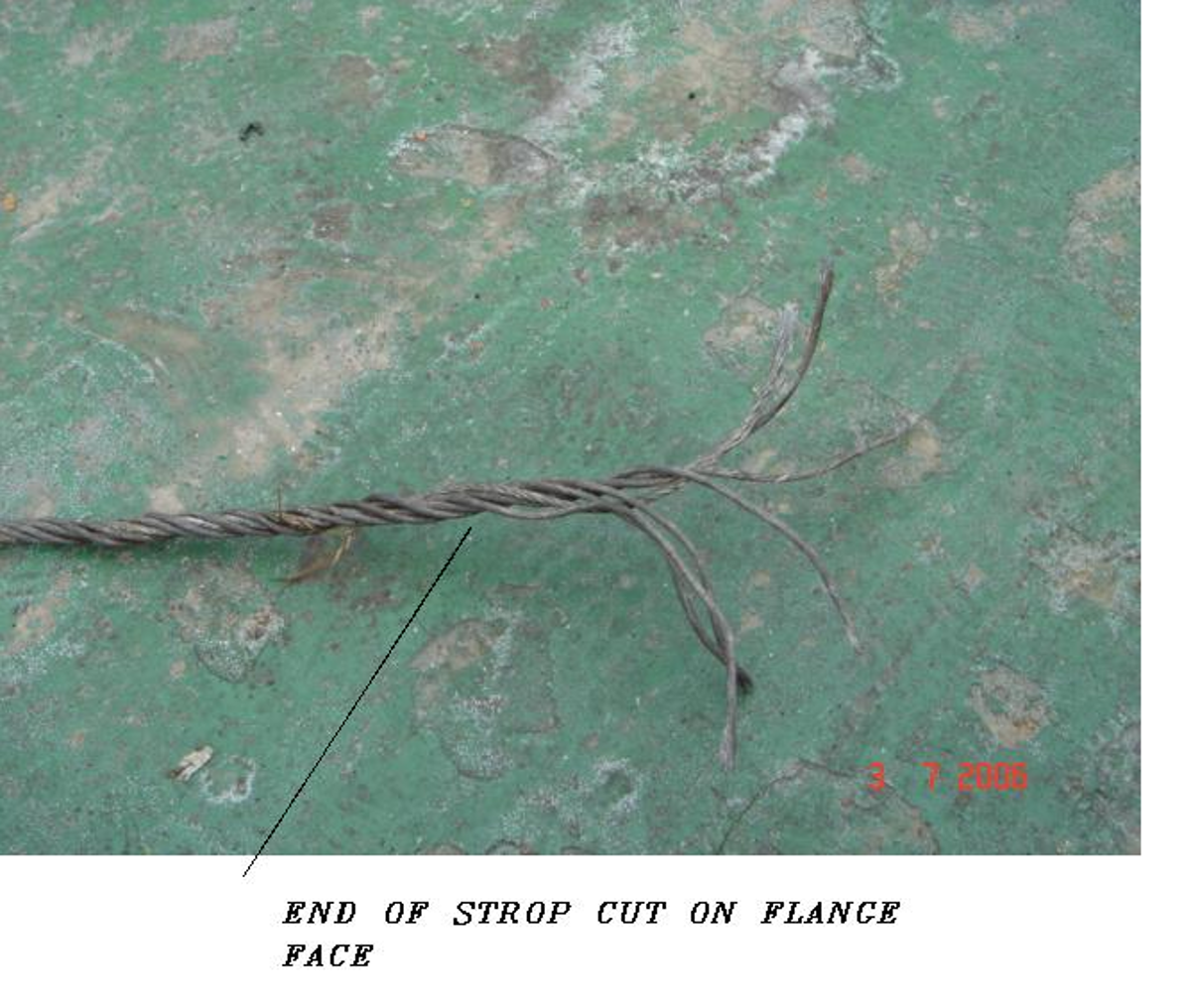

The diver was asked to inflate a 5 tonne air lift bag, which had swaged half inch wire strop passing through the 12 o’clock bolt hole position on tie-in flanges. The lift bag was being used to lift and align flanges in position prior to bolt installation. While filling the lift bag, the diver was asked by the diving supervisor to double-check the attached rigging. The diver reported a sharp bend on the wire strop through the 12 o’clock bolt hole of the flange end which went up to the lift bag. As a precaution, the supervisor instructed the diver to stop inflating the airbag, to deflate and remove the airline.

While he was undoing the airline, which was made cold, the wire strop parted, causing the lift bag and airline to come to the surface around 20 metres from port side of the vessel. The diver was on a clear path to the bell with his umbilical and was far away from the air bag rigging attachment, thus averting possible entanglement. The company notes that this avoided what could potentially have been a fatality. The diver was reported well after the incident.

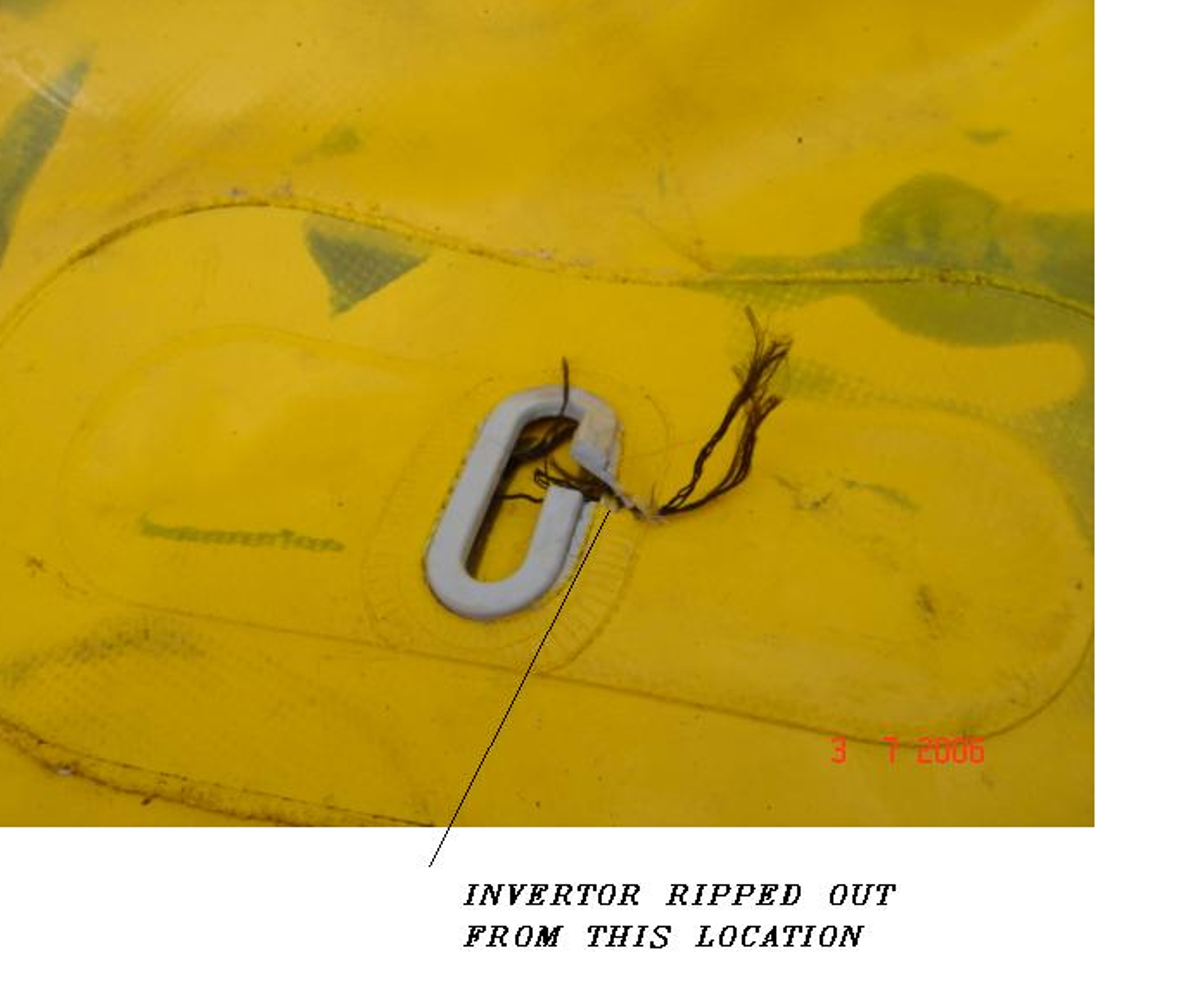

On inspection of the air lift bag, it was found that the inverter line attached to the top of the bag had pulled out, resulting in the lift bag failing to spill the air contained and the bag reaching the surface. The diver reported that the bag was only half to two-thirds full in capacity at the time of the incident.

The company identified the following contributory factors:

- The less-than half inch wire rope strop passing through the flanges and attached to the air lift bag had not been certified.

- The inverter line pulled out of the top tab (the tab burst) and thus the air bag could not be inverted.

- The suitability of the rigging had not been thoroughly checked prior to lowering the air bags to the seabed.

The following points were identified as helping avoid an even more serious incident:

- Timely observation by the supervisor and his instruction to the diver to check the rigging while inflating the lift bag.

- The diver and his umbilical were out of the ascent path of the air lift bag, thus avoiding what could potentially have become a fatality.

The company has taken the following corrective measures following the incident:

- The incident was discussed in toolbox meetings and the potential effects were discussed by the diving superintendent and OCM.

- The dive team has been reminded of the importance of checking all rigging prior to attachment to loads and of following proper lifting procedures.

- The rigging gear onboard the vessel has been inspected both for any damage and to ensure it is properly certified.

- The air bag supplier is further investigating the incident.

The company has issued a reminder that lifting incidents, including air bag lifting, carry the potential for serious injuries and fatalities to occur, reiterating the need to follow proper procedures, to review lifts at toolbox meetings before they commence and to keep abreast of company and industry guidance on the subject.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.