Lost anchor chain

- Safety Flash

- Published on 31 October 2005

- Generated on 12 February 2026

- IMCA SF 10/05

- 2 minute read

Jump to:

IMCA has received a report of a vessel losing one anchor and four lengths of chain cable during anchor handling.

What happened?

During the vessel’s previous dry docking, a number of chain cable lengths had been renewed on both port and starboard sides, including a number of Kenter shackles (joining shackles) as found necessary, due to wastage in excess of allowable limits. The remaining part of the anchor chain cable lengths and Kenter shackles were at that time found to be in satisfactory condition.

What were the causes?

It was discovered on investigation that the probable cause of the damage was the fracture of a Kenter shackle that had not been renewed in the previous dry dock.

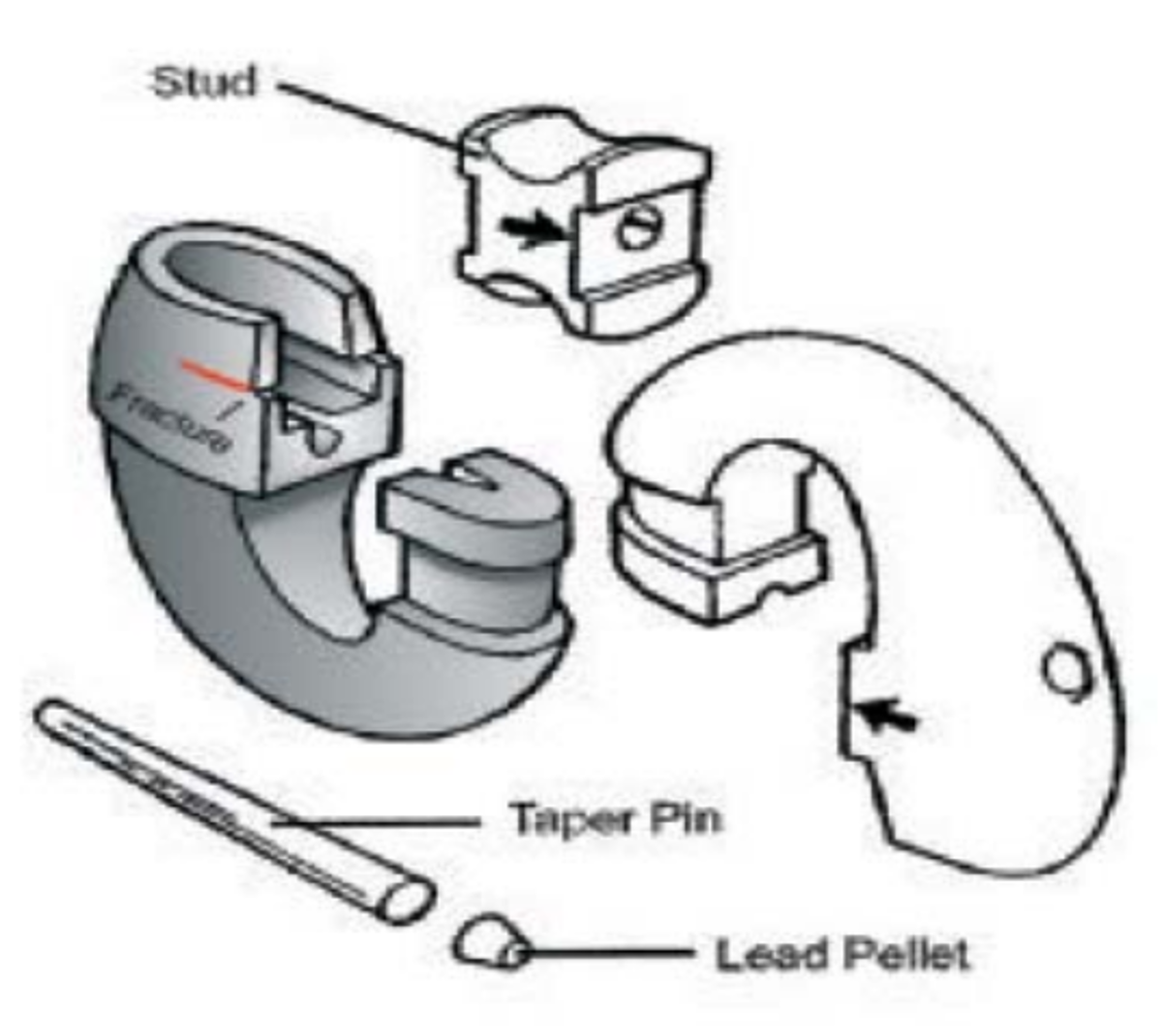

Note that the intricate shape of the various parts of a Kenter shackle means that large forces are transferred through relatively small contact areas. Proper design and well machined faces and corners are very important for the durability of such shackles.

In the above case the failure may be attributed to mishandling of the Kenter shackle during the opening/ fitting operation. Since in most cases Kenter shackles on old anchor chains are rusty/frozen, and opening up and reassembly requires the use of heating or mechanical force, cracks are likely to develop and should result in replacement rather than re-use.

Lessons learnt

The lesson to be learnt from this incident is, when a chain cable length is replaced due to wear and tear, the Kenter shackle(s) are normally worn as well and should generally be replaced.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.