Potential for diver injury operating a hand-held torque wrench

- Safety Flash

- Published on 31 March 2020

- Generated on 10 February 2026

- IMCA SF 09/20

- 2 minute read

Jump to:

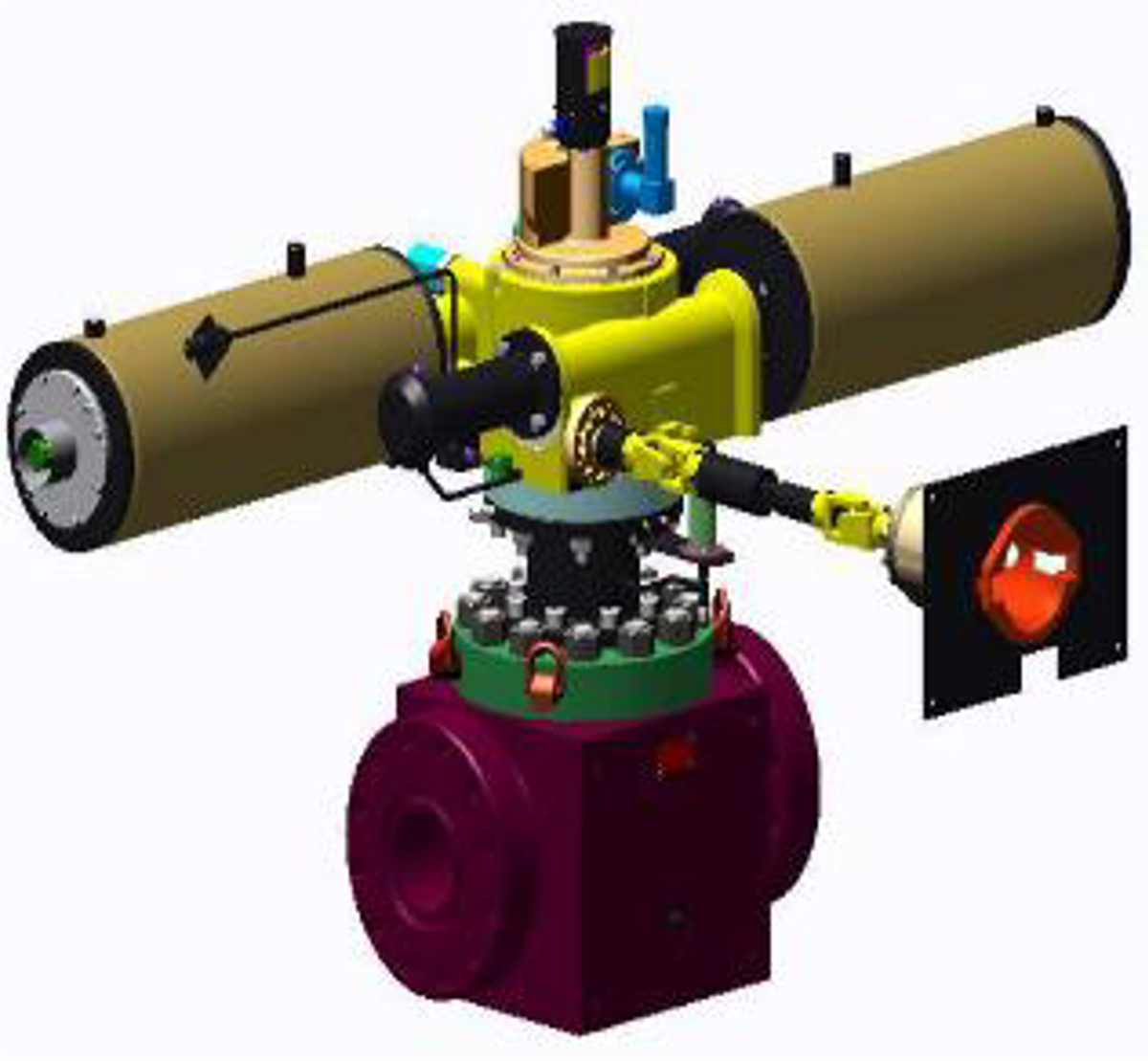

A diver was involved in a near miss that could have resulted in serious injury when he was asked to function an ROV valve override on a subsea isolation valve with a hand-held torque wrench

What happened?

The diver was asked to operate an ROV override switch with a hand-held torque wrench.

The operation was observed by a third-party technician who intervened and stopped the job.

The use of a hand-held torque wrench to operate an ROV override on the valve was inappropriate due to the possibility of a sudden uncontrolled unwinding of the spring mechanism, which could have caused the torque wrench to rotate and hit the diver.

What went wrong?

- The warnings on the GA (general assembly) drawing stating that hand-held tools should not be used were ambiguous and were missed.

- The valves procedure issued by the client did not include a warning or highlight the dangers of using hand-held tools to operate the ROV override.

- Engineers were not issued with the appropriate installation operations manual, which included warnings not to use hand-held tools.

- The assumption was made that a hand-held torque wrench could be used. Our member notes that similar incidents have occurred within the organisation.

What actions were taken?

Any operation of an ROV override on a double actuated spring ¼ turn ball valve (fail safe) should not be operated with a manual hand-held torque tool, unless there is clear confirmation from the client or the valve manufacturer that it is safe to do so.

Related Safety Flashes

-

IMCA SF 19/17

2 August 2017

-

-

IMCA SF 10/17

12 May 2017

-

-

IMCA SF 08/17

12 April 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.