Machine guarding

- Safety Flash

- Published on 1 August 2003

- Generated on 24 April 2025

- IMCA SF 09/03

- 2 minute read

Jump to:

Employee exposure to unguarded or inadequately guarded machines is prevalent in many workplaces. Amputations are one of the most severe and crippling types of injuries in the occupational workplace.

All personnel have to be focused on recognising and controlling common amputation hazards associated with the operation and use of certain types of machines.

A member has recently issued advice to its employees as follows:

All machines consist of three fundamental areas:

- The point of operation

- The power transmission device

- The operating controls

Despite all machines having the same basic components, their safeguarding needs differ widely due to varying physical characteristics and operator involvement.

- Safeguards are essential for protecting workers from these needless and preventable injuries

- Any machine part, function, or process which may cause injury must be safeguarded

- When the operation of a machine or accidental contact with it can injure the operator or others in the vicinity, the hazards must be either eliminated or controlled.

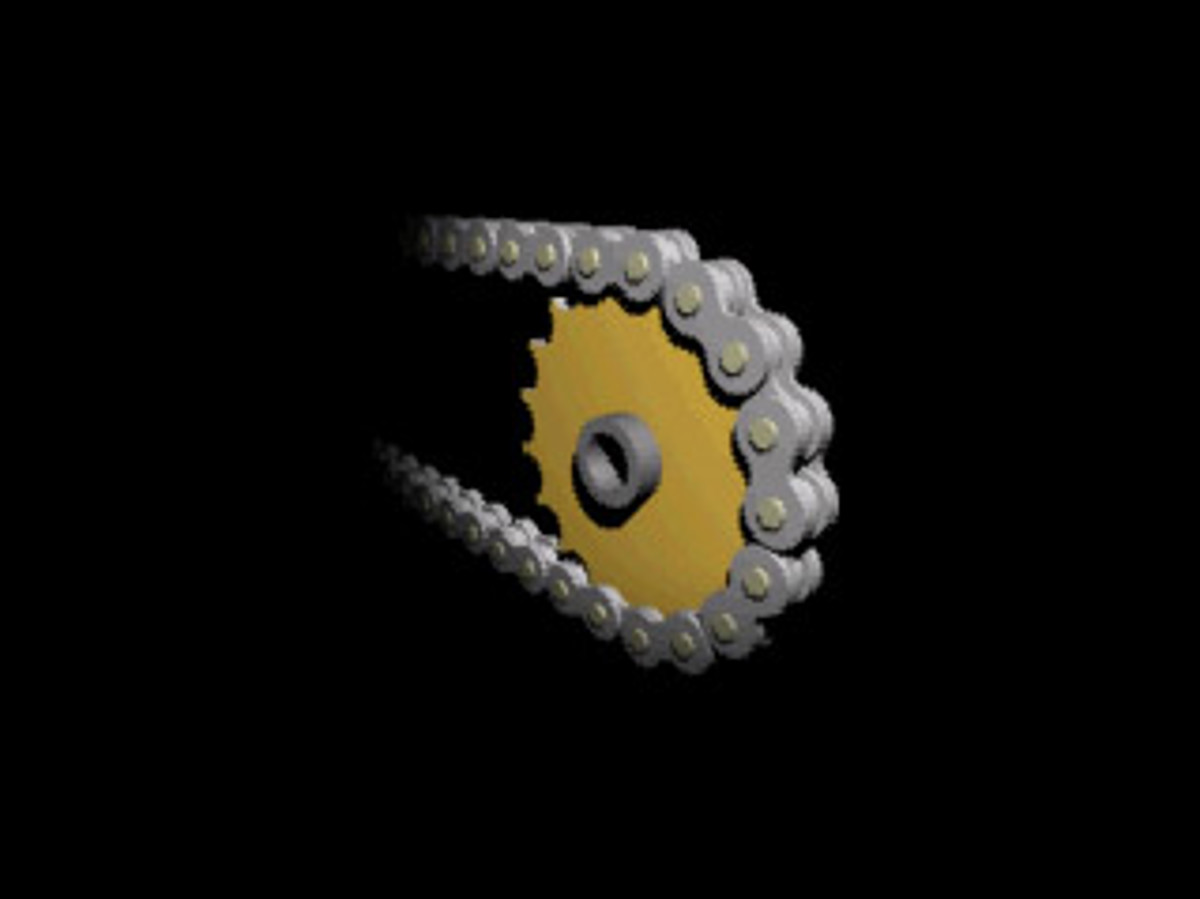

In-running nip points

Nip points can occur between rotating and In-running nip points fixed parts which create a shearing, crushing, or abrading action.

Hazards are caused by the rotating parts on machinery. Parts can rotate in opposite directions while their axes are parallel to each other.

Are also created between rotating and tangentially moving parts.

Rotating motion

Can be dangerous; even smooth slowly rotating shafts can grip hair and clothing, and through minor contact force the hand and arm into a dangerous position.

Reciprocating motions

May be hazardous because, during the back and forth or up-and-down motion, a worker may be struck by or caught between a moving and a stationary part.

Transverse motion

By movement in straight, continuous line, creates a hazard because a worker may be struck or caught in a pinch or shear point by the moving part.

Cutting action

The danger of cutting action exists at the point of operation where finger, arm and body injuries can occur and where flying chips or scrap material can strike the head, particularly the eyes or face.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.