Near miss: Cargo shifted on deck in heavy weather

- Safety Flash

- Published on 18 April 2019

- Generated on 10 February 2026

- IMCA SF 07/19

- 2 minute read

Jump to:

A platform supply vessel (PSV) was on ‘stand-by’ near an offshore Installation waiting on weather.

What happened?

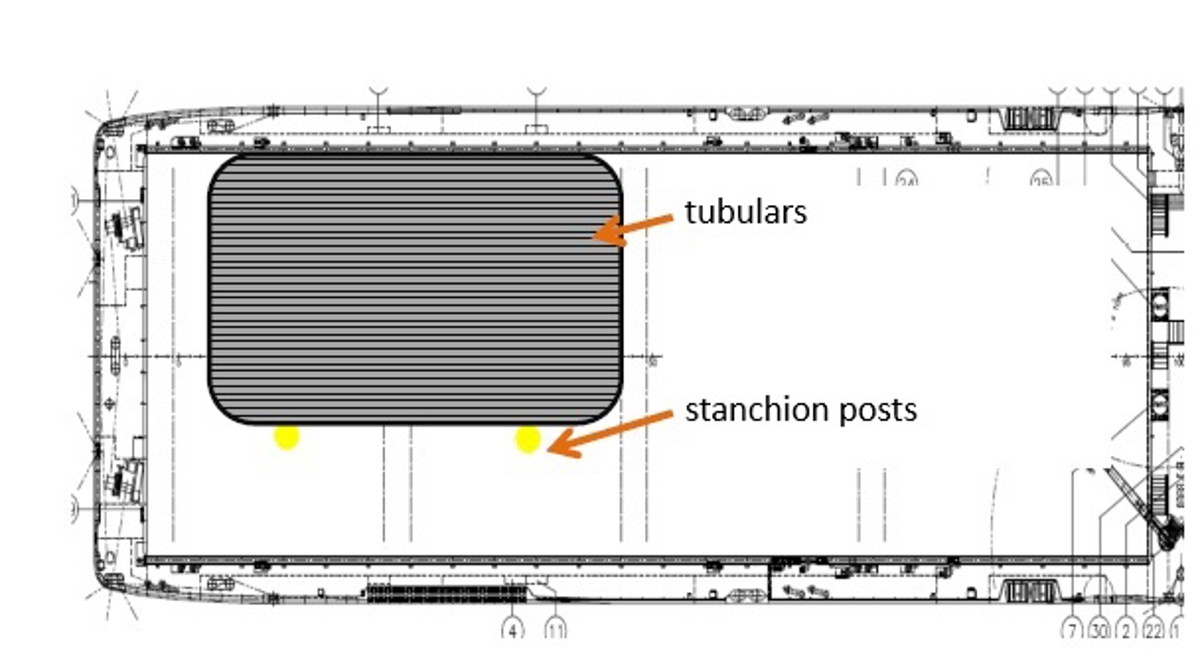

Owing to the sea conditions, the vessel was pitching and rolling heavily. A load of 20” casing had been back-loaded earlier; this load covered two-thirds of the width of the deck on the port side and was stacked two layers high. The casing was secured with pipe stanchion pins. However, on taking a particularly heavy roll to starboard, the pipe stanchions sheared, causing the load to move/roll approximately 3m to starboard, ending up resting against other back loaded cargo.

Weather conditions at the time were: wind gusting up to 45 knots, sea state: 5-6m. As per vessel procedures, no personnel were on deck at the time.

What went wrong?

Both stanchion pins sheared at the base/weld (see images below).

It is believed this incident happened because there was a small gap of 10-15 cm between the forward pin and the casing, which allowed additional load on the after pin when the vessel was rolling, thus causing the aft pin to shear.

The most recent visual inspections of the pins were within the last three months and were found to be in a satisfactory condition. However, it was later identified that the pins were several years old and had been in use frequently during adverse weather/winter conditions.

What were the causes?

- Incorrect securing method.

- Poor back-load planning (space between tubular and stanchion pin allowed movement).

- The welds on stanchion pins failed.

- Weather and sea conditions.

What actions were taken?

Increased focus on back-load planning and placement of equipment on deck:

- Box in loads with heavier back-load (this would have occurred on this vessel, however, in this case operations were suspended by the crane operator on the installation, due to excessive wind speed).

- Re-assessment of life-span of securing pins. All pins were replaced with new and welds were subject to non-destructive examination (NDE);

During loading/back-loading of casing, risk assessment regarding possible additional stanchion pins was needed, especially during winter periods.

Related Safety Flashes

-

IMCA SF 29/16

24 October 2016

-

IMCA SF 17/16

30 June 2016

-

IMCA SF 01/12

25 January 2012

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.