Near-miss: Laundry fire hazards

- Safety Flash

- Published on 31 March 2016

- Generated on 8 February 2026

- IMCA SF 07/16

- 3 minute read

Jump to:

Two members have reported recent near misses which might have developed into fires in the laundry room.

Incident 1

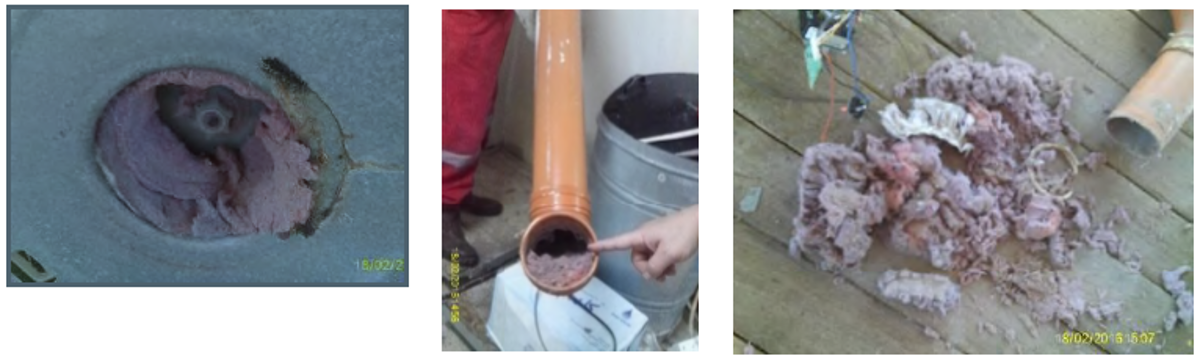

A member has reported a near miss which might have developed into a fire in the laundry room. During a weekly inspection of the laundry room, rags and lint twisted together were discovered in the dryer exhaust fan. Further investigation revealed more accumulated lint within the dryer’s outlet exhaust pipe. When the end of the outlet pipe was removed to check the inside, it was found that it was approximately 85% blocked by lint.

Our member’s investigation revealed the following:

- Athough the dryer’s lint filter was in place at the time, the evidence clearly indicates that it hadn’t always been in use, or had been used incorrectly – the correct use and installation, and frequent checking of, lint filters is essential to avoid such potentially hazardous situations.

- Use of ventilation pipes and systems can create traps in which lint accumulates over a period of time, especially if lint traps are not in use or defective – this creates a fire hazard. Such venting systems should be regularly checked to ensure that they are free of obstructions.

- There was no management of change (MoC), risk assessment or forward planning conducted to fully assess the impact of fitting the venting pipe.

Our member took the following actions:

- Immediately removed the outlet exhaust pipe for thorough cleaning and removal of lint.

- Subsequently, the dryers were relocated to an external area (winch housing) where they could vent directly to atmosphere.

What lessons were learned?

- Routine inspections are important – they exist for a reason. Don’t let ‘checklist’ mentality take over. If the persons involved here hadn’t taken the time to carry out a proper inspection, there could have been an actual fire rather than a near miss

- Ensure that health and hygiene inspections have the same priority as other safety inspections

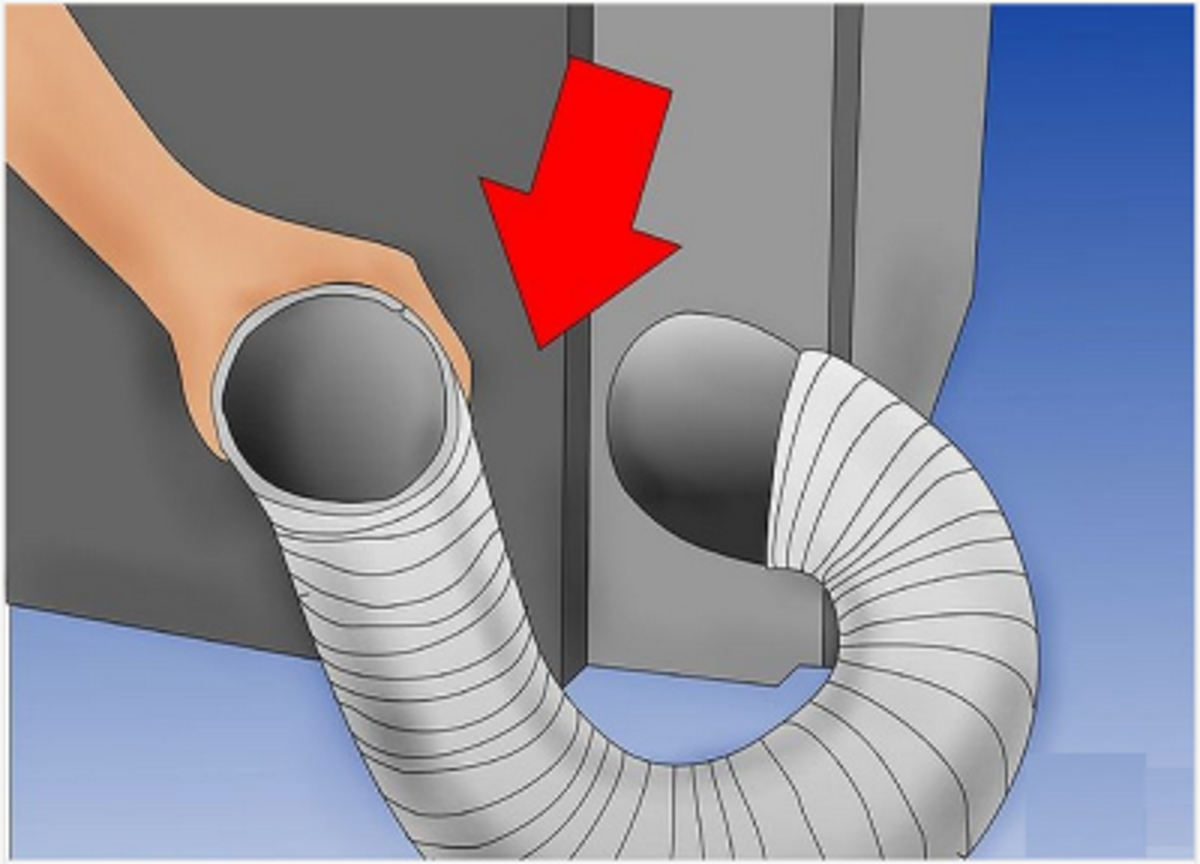

- Take extra care when dealing with tumble dryers with outlet pipe connections – with the permanent connection of a pipe, it is more difficult to identify any blockages or obstructions, and motors are exposed to increased load and overheating. Wherever possible, fitting/use of additional piping should be avoided

- In this case, the vessel management decided to go beyond checklists – the decision was taken to conduct electrical and cleanness checks in the dryer, going beyond the minimum required.

Incident 2

During a ‘routine’ UK Health & Safety Executive (HSE) inspection, a potentially hazardous condition was observed which could have caused a fire. The vessel master and crew were unaware of the potential consequences of the accumulation of flammable lint inside tumble-drying machines. A small spark, a short circuit or static electricity inside of the machine could have been sufficient enough to start a fire.

Our member provided the following handy graphic which may be of use:

Related Safety Flashes

-

IMCA SF 03/16

27 January 2016

-

IMCA SF 16/09

10 November 2009

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.