Second-hand equipment causes engine breakdown

- Safety Flash

- Published on 29 May 2015

- Generated on 18 April 2025

- IMCA SF 07/15

- 3 minute read

Jump to:

A Member has reported an incident in which an offshore wind farm Crew Transfer Vessel (CTV) suffered an engine breakdown due to the drive belt automatic tensioner seizing.

What happened?

The incident occurred whilst the vessel was on transit from harbour to site. The port engine alarm activated, it was quickly discovered after short investigation that the main engine auxiliary belt that drives the alternator and the cooling pump had broken and the belt tensioner was badly damaged.

The CTV had to return to harbour using one engine only, to allow for further investigation and the repairs to be safely carried out. The damaged parts were removed by the crew and replaced with onboard spares.

drive belt tensioner

drive belt tensioner

Findings

Our member’s investigation noted the following:

- The belt tensioner that failed had been fitted to the engine second-hand only two months previously, and its age and run time were unknown.

- The replacement part was only intended to be a short term solution until a new belt tensioner could be sourced and fitted.

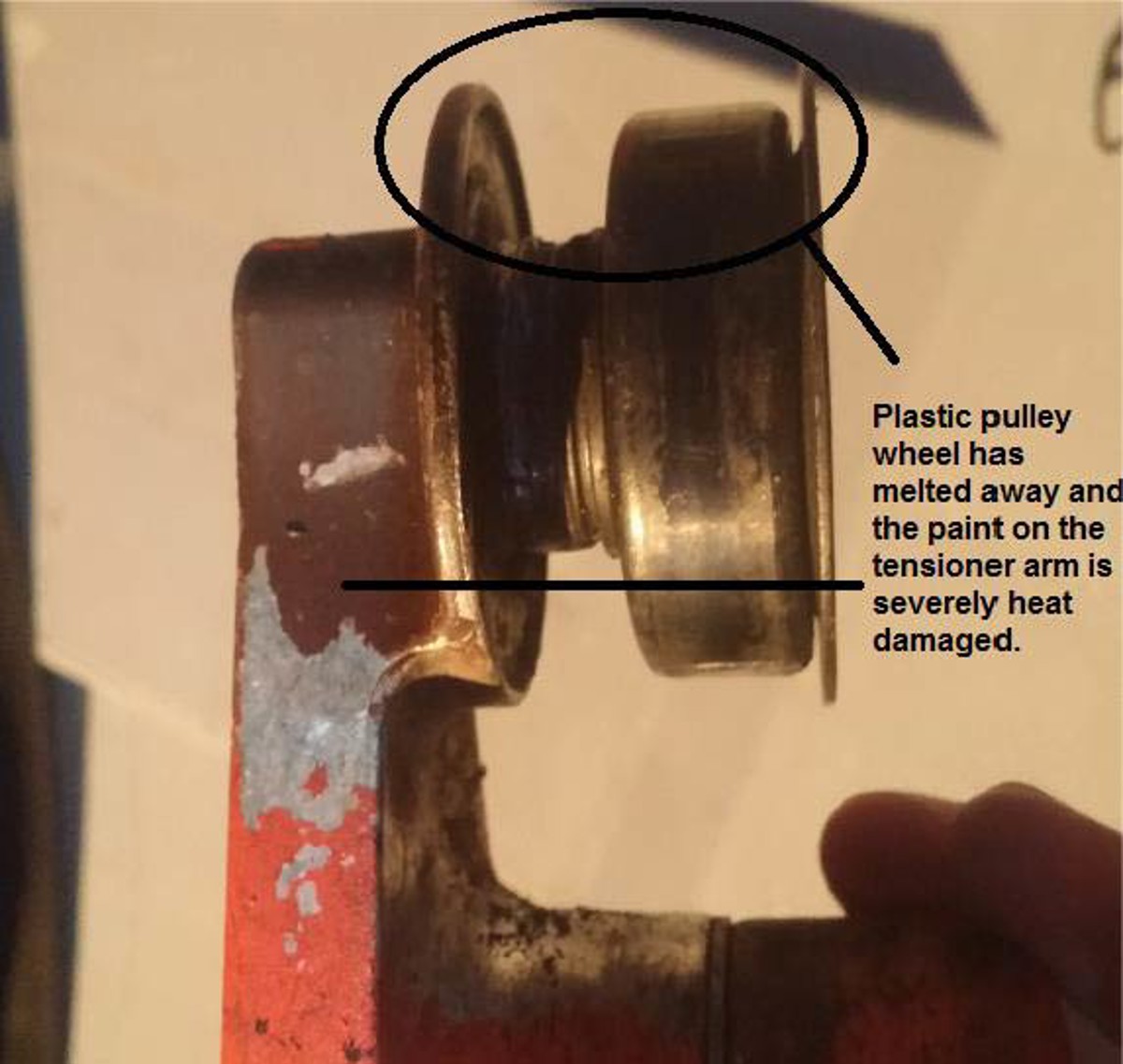

- The bearings had fallen apart and the pulley wheel seized causing the belt to run over the stationary plastic wheel until friction caused failure.

- The engine manufacturer recommended that checks be made every twelve hours.

- To see if the drive belt was damaged or worn.

- To see if the automatic belt tensioner was in proper working order and keeps the belt correctly tensioned.

- The service check sheets showed that these checks had been made at the previous services.

- The service report/invoice had been checked and there was no mention of the tensioner arm being replaced by a second hand spare but that it would be replaced covered by manufacturer’s warranty.

- The crew did not write any notes to their opposite shift to alert them of the second hand tensioner arm being used to fix the problem and therefore there was no further communication regarding the future renewal of this equipment.

- The engine maintenance log also did not mention that the tensioner replacement was a second hand spare.

- When the new tensioner arrived onboard the crew were not aware that they needed to change the second-hand spare with it; the engine manufacturer had not informed either the crew or the management that the new part should be fitted upon arrival.

- It was noted that whilst the belt tensioner could be and was checked, it was very difficult to accurately check the pulley bearing as it was a sealed unit with no means of lubrication during its working life (only at manufacture) and it was not possible to see the condition of the bearing.

- The engine manufacturer offered no guidance advising on a lifespan or recommended change time for the belt or tensioner.

Lessons learned

Our Member drew the following lessons:

- Servicing guidelines and procedures: improvements were made to on-board servicing guidelines for engines of this sort.

- Communications and record-keeping: comprehensive and proper records should be made in the vessel maintenance log – and forwarded to management ashore – when changes were made to the engine, or parts therein were replaced.

Related safety flashes

-

IMCA SF 02/15

5 February 2015

-

IMCA SF 10/14

30 June 2014

-

IMCA SF 12/13

19 July 2013

-

IMCA SF 01/11

27 January 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.